Nissan Airbag Module Reset

Airbag systems are critical safety components in modern vehicles, designed to mitigate injuries during collisions. When an airbag deploys in a Nissan vehicle, the airbag control module (ACM), also known as the Supplemental Restraint System (SRS) unit, stores crash data. This data prevents the system from functioning correctly, even after replacing deployed airbags and sensors. The process of resetting this module to its pre-deployment state is known as airbag module reset. This article delves into the technical aspects of Nissan airbag module reset, comparing it with alternatives, discussing reliability, maintenance, and future trends.

Understanding the Nissan Airbag System

The Nissan airbag system is a sophisticated network of sensors, actuators, and the ACM. Sensors strategically placed throughout the vehicle, such as frontal impact sensors, side impact sensors, and seat occupancy sensors, constantly monitor crash conditions. When a collision is detected, these sensors send signals to the ACM. The ACM processes this data based on pre-programmed algorithms. If the severity of the impact exceeds predefined thresholds, the ACM triggers the deployment of airbags and seatbelt pretensioners. The ACM records crucial data points such as impact force, direction, and airbag deployment timing. This crash data is stored in the ACM's non-volatile memory, effectively disabling the system until it is reset or replaced.

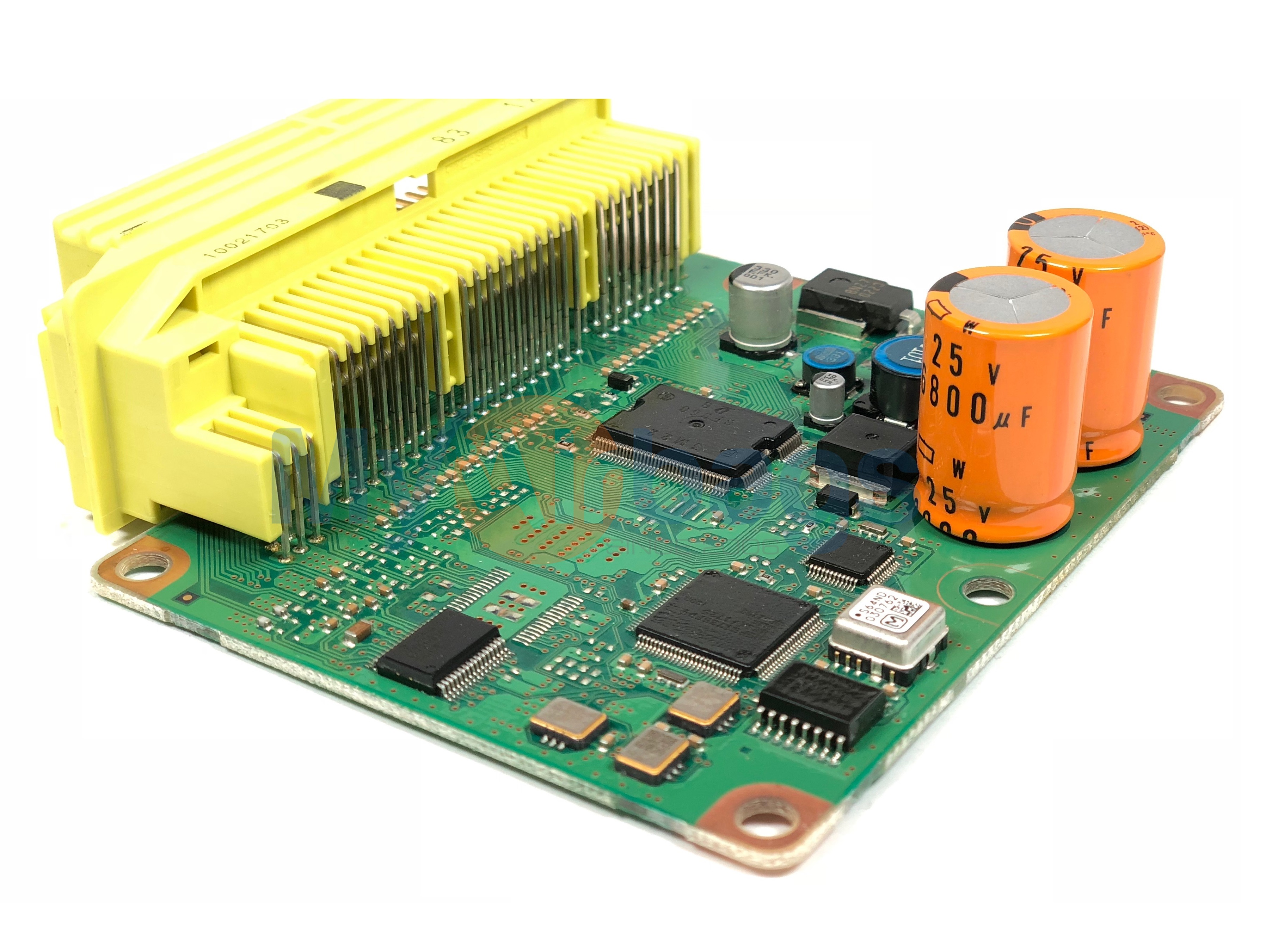

Technical Specifications of Nissan ACMs

Nissan ACMs typically utilize microcontrollers with integrated flash memory for storing program code and crash data. Common microcontroller families include those from Renesas and Infineon. These microcontrollers feature robust error detection and correction mechanisms to ensure data integrity. The ACM communicates with other vehicle systems via Controller Area Network (CAN) bus. The CAN bus allows the ACM to receive data from various sensors and transmit deployment signals to the airbags and seatbelt pretensioners. Voltage requirements are typically 12V DC, with specific current draws varying depending on the model and year. Diagnostic interfaces include OBD-II (On-Board Diagnostics II) for accessing diagnostic trouble codes (DTCs) and performing system tests.

Methods for Nissan Airbag Module Reset

Several methods exist for resetting Nissan airbag modules, each with its own advantages and disadvantages. These can be broadly categorized into:

- Software-Based Reset: This method involves using specialized diagnostic tools and software to clear the crash data from the ACM's memory. These tools often connect to the vehicle's OBD-II port and communicate with the ACM to overwrite the crash data section of the memory.

- Hardware-Based Reset: This method involves physically accessing the ACM's memory chip and using a chip programmer to erase or modify the crash data directly. This requires desoldering the memory chip from the ACM's circuit board.

- Module Replacement: Replacing the ACM with a new or refurbished unit is the most straightforward, but also the most expensive option. A new ACM will require programming to the vehicle's VIN (Vehicle Identification Number) and may need to be coded to match the specific vehicle configuration.

Software-Based Reset: Pros and Cons

Pros:

- Relatively easy and quick procedure compared to hardware-based methods.

- No need to physically remove the ACM from the vehicle in most cases.

- Less risk of damaging the ACM.

Cons:

- Requires specialized diagnostic tools and software, which can be costly.

- Not all software tools are compatible with all Nissan ACM models.

- Some software tools may be unreliable or contain bugs.

- Can be bypassed by certain modules.

Hardware-Based Reset: Pros and Cons

Pros:

- Can be used on a wider range of Nissan ACM models, including those not supported by software tools.

- Provides more direct control over the memory reset process.

Cons:

- Requires advanced technical skills in electronics and soldering.

- High risk of damaging the ACM's circuit board or memory chip during desoldering and soldering.

- Time-consuming and labor-intensive.

- Requires purchasing specialized chip programmers.

Module Replacement: Pros and Cons

Pros:

- Guaranteed to reset the airbag system.

- Reduces potential liability issues associated with resetting a damaged module.

Cons:

- Most expensive option.

- Requires programming the new module to the vehicle's VIN and configuring it to match the vehicle's options.

- May need to source a compatible module, which can be time-consuming.

Comparison with Alternatives

Besides resetting or replacing the airbag module, other options might seem viable but come with serious drawbacks. One option is using an airbag emulator, which tricks the system into thinking the airbags are functioning correctly. However, this is highly dangerous and illegal in many jurisdictions as it disables the airbag system's functionality entirely, offering no protection in the event of a collision. Similarly, simply clearing the airbag warning light without addressing the underlying crash data in the ACM is equally dangerous and irresponsible. These approaches should never be considered.

Reliability Aspects

The reliability of a reset airbag module depends heavily on the method used for resetting and the condition of the module before the reset. Software-based resets, when performed correctly with reliable tools, can be quite reliable. However, if the ACM has suffered physical damage during the collision, a reset may not restore full functionality. Hardware-based resets are generally considered less reliable due to the risk of damage during the desoldering and soldering process. A replacement module, if properly programmed and configured, offers the highest level of reliability.

Maintenance Tips

To ensure the ongoing reliability of the airbag system after a reset or replacement, the following maintenance tips should be followed:

- Regularly inspect the airbag system for any warning lights or DTCs.

- Check the condition of the airbag connectors and wiring harnesses for corrosion or damage.

- Ensure that the seat occupancy sensors are functioning correctly.

- If any issues are detected, promptly address them by a qualified technician.

Future Trends

The automotive industry is constantly evolving, and airbag systems are no exception. Future trends in airbag technology include:

- Advanced Airbag Designs: Airbags that deploy with variable force based on the occupant's size, weight, and seating position.

- External Airbags: Airbags that deploy outside the vehicle to mitigate impact forces before a collision.

- Integration with Autonomous Driving Systems: Airbag systems that can anticipate collisions and deploy pre-emptively based on data from autonomous driving sensors.

- Enhanced Diagnostics and Remote Monitoring: More sophisticated diagnostic capabilities and remote monitoring of airbag system health.

- Improved Cybersecurity: Robust security measures to protect airbag systems from hacking and unauthorized access.

Conclusion

Nissan airbag module reset is a complex procedure requiring specialized knowledge and equipment. While software-based and hardware-based reset methods offer cost-effective alternatives to module replacement, they also carry inherent risks. The choice of method depends on the technician's skills, the condition of the ACM, and the specific requirements of the vehicle. Replacement remains the safest, though most expensive, approach. As the automotive industry moves towards more advanced safety technologies, the complexity of airbag systems will continue to increase. Automotive professionals must stay updated with the latest diagnostic techniques and repair procedures to ensure the safety and reliability of these critical safety systems. The future of automotive safety depends on continuous learning and adaptation to these rapidly evolving technologies. The emphasis on data security and system integration will be paramount.