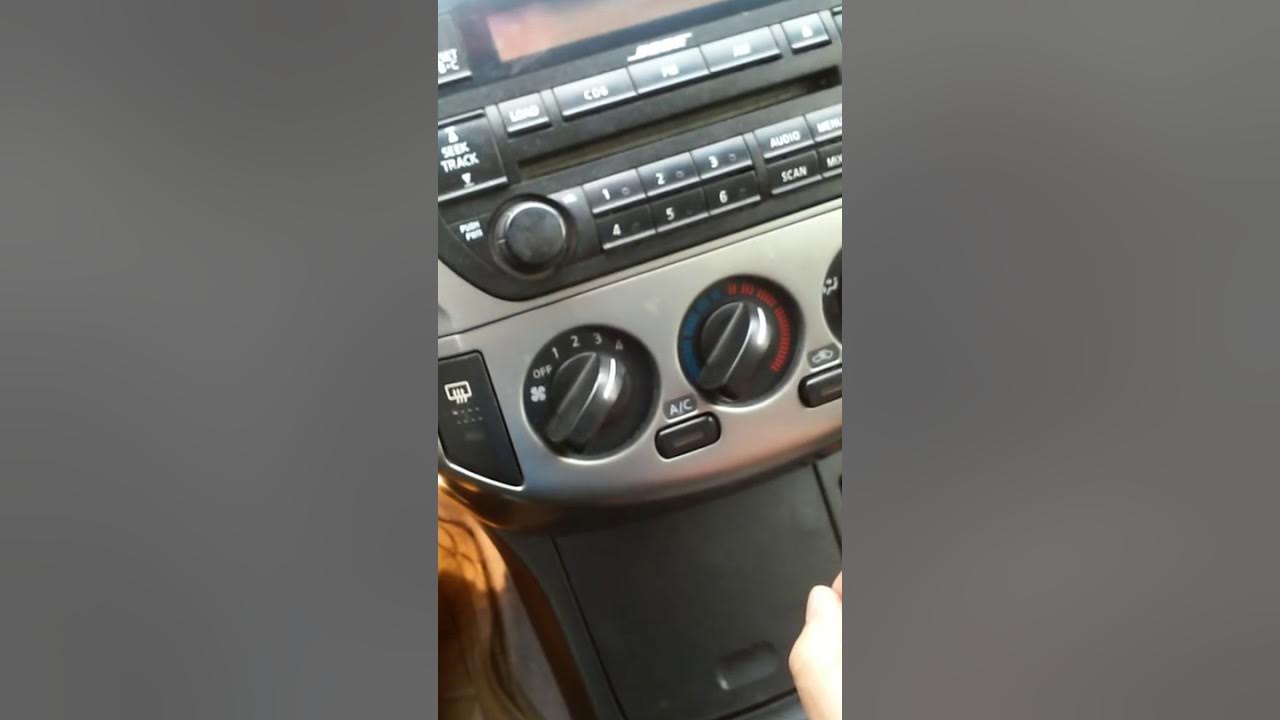

Nissan Altima Blowing Hot Air

Diagnosing why your Nissan Altima is blowing hot air when it should be providing a refreshing blast of cold AC can be a frustrating experience. Instead of simply throwing parts at the problem, a systematic approach, combined with a solid understanding of the Altima's air conditioning system, will yield the best results. This guide will delve into the common culprits behind this issue, explaining the underlying principles at play.

Understanding the Altima's AC System

Before we begin troubleshooting, it's crucial to understand the core components of the Altima's AC system and how they work together. The system fundamentally operates on the principle of refrigeration – transferring heat from inside the cabin to the outside.

- Compressor: The heart of the system, the compressor compresses the refrigerant gas, increasing its pressure and temperature. It's driven by the engine via a belt. A faulty compressor is a common cause for AC failure.

- Condenser: Located in front of the radiator, the condenser dissipates heat from the high-pressure, high-temperature refrigerant gas, causing it to condense into a high-pressure liquid. Airflow across the condenser is vital for efficient heat exchange.

- Receiver-Drier (or Accumulator): This component acts as a filter, removing moisture and contaminants from the refrigerant. It also stores a small amount of liquid refrigerant.

- Expansion Valve (or Orifice Tube): This device meters the flow of high-pressure liquid refrigerant into the evaporator. It causes a sudden pressure drop, allowing the refrigerant to expand and evaporate, absorbing heat in the process. Altimas might use either an expansion valve or an orifice tube, depending on the year and model.

- Evaporator: Situated inside the dashboard, the evaporator is where the refrigerant absorbs heat from the cabin air. As the refrigerant evaporates, it cools the evaporator core, and a blower motor forces air across the core, providing cool air to the vents.

- Refrigerant: The working fluid that carries heat throughout the system. Low refrigerant levels are a very common cause of AC problems.

Common Causes and Troubleshooting Steps

1. Low Refrigerant Levels

This is perhaps the most frequent reason for a Nissan Altima blowing hot air. Refrigerant leaks are common, especially in older vehicles. The refrigerant not only carries heat, but also carries oil to lubricate the compressor. Low refrigerant will damage the compressor.

Troubleshooting:

Visual Inspection: Look for visible signs of leaks around the compressor, condenser, refrigerant lines, and other components. Oily residue is a telltale sign.

Gauge Test: Use a manifold gauge set to measure the high and low-side pressures. Compare the readings to the specifications in your Altima's service manual. If the pressures are significantly low, it indicates a leak.

Leak Detection: If you suspect a leak but can't find it visually, use a refrigerant leak detector (electronic sniffer) or inject a UV dye into the system and use a UV light to identify the source of the leak. Always wear appropriate safety glasses when working with refrigerants and UV dye.

Solution: Repair any leaks, evacuate the system (remove all air and moisture), and recharge with the correct type and amount of refrigerant, according to the service manual. This is best left to a professional unless you have the necessary equipment and expertise.

2. Faulty Compressor

If the compressor isn't functioning correctly, it won't be able to circulate the refrigerant, resulting in no cooling. The compressor clutch should engage when AC is turned on.

Troubleshooting:

Clutch Engagement: Check if the compressor clutch is engaging when the AC is turned on. You should hear a distinct click and see the clutch plate on the front of the compressor spinning. If it's not engaging, check the AC relay and fuse. Also, a low refrigerant level will prevent the compressor clutch from engaging to protect the compressor.

Voltage Test: Use a multimeter to check if voltage is reaching the compressor. If there's voltage but the clutch isn't engaging, the clutch itself is likely faulty.

Internal Failure: Even if the clutch engages, the compressor might have internal damage. This can be diagnosed by measuring the high and low-side pressures with a manifold gauge set. Unusual pressure readings can indicate internal compressor failure.

Solution: Replace the compressor. It's highly recommended to also replace the receiver-drier (or accumulator) and expansion valve (or orifice tube) when replacing the compressor to prevent contamination of the new compressor with debris from the old one. Have the system professionally evacuated and recharged.

3. Condenser Issues

A blocked or damaged condenser can prevent proper heat dissipation, leading to poor AC performance. Debris like leaves, bugs, or damage from road hazards can restrict airflow.

Troubleshooting:

Visual Inspection: Carefully inspect the condenser for any obstructions or damage. Straighten any bent fins to improve airflow.

Temperature Check: With the AC running, carefully feel the condenser. It should be warm, but not excessively hot. Uneven temperatures can indicate blockage.

Solution: Clean the condenser thoroughly. If it's severely damaged, it needs to be replaced. Make sure to have the system evacuated and recharged by a qualified technician.

4. Expansion Valve/Orifice Tube Problems

A clogged or malfunctioning expansion valve (or orifice tube) can restrict refrigerant flow, impacting cooling performance. A clogged valve will also damage the compressor over time.

Troubleshooting:

Pressure Test: Using a manifold gauge set, check the high and low-side pressures. Unusual pressure readings (e.g., very low low-side pressure) can indicate a problem with the expansion valve or orifice tube.

Visual Inspection (Difficult): The expansion valve is typically located inside the evaporator case, making visual inspection difficult without disassembly. The orifice tube is located in the liquid line and can be inspected after removing the line.

Solution: Replace the expansion valve or orifice tube. As mentioned before, it's advisable to replace these components when replacing the compressor to prevent contamination. Have the system evacuated and recharged professionally.

5. Blower Motor Issues

Even if the AC system is functioning correctly, a faulty blower motor can prevent cool air from reaching the cabin vents. A weak or non-functioning blower motor restricts the airflow across the evaporator core.

Troubleshooting:

Blower Speed Test: Check if the blower motor operates at all speeds. If it only works on some speeds, the blower motor resistor is likely faulty.

Voltage Test: Check if voltage is reaching the blower motor. If there's no voltage, check the blower motor relay and fuse.

Solution: Replace the blower motor or blower motor resistor as needed. This is generally a straightforward repair.

6. Electrical Problems

Faulty wiring, relays, fuses, or sensors can disrupt the AC system's operation.

Troubleshooting:

Fuse Check: Start by checking all relevant fuses in the fuse box (both under the hood and inside the cabin).

Relay Check: Test the AC relay and compressor clutch relay. You can often swap relays with a known working relay of the same type to see if that resolves the issue.

Wiring Inspection: Carefully inspect the wiring harness for any damaged or corroded wires. Use a multimeter to check for continuity.

Solution: Repair or replace any faulty wiring, relays, or fuses. Electrical diagnostics can be challenging and may require a professional technician.

7. Blend Door Actuator

The blend door controls the mixture of hot and cold air entering the cabin. A faulty blend door actuator can cause the door to get stuck in the hot position, even when the AC is on.

Troubleshooting:

Actuator Function: Turn the temperature control from cold to hot while listening near the dash. You should hear the actuator motor whirring and the door moving. If not, the actuator may be faulty.

Visual Inspection: In some models, you can access and visually inspect the blend door actuator. Look for any physical damage or disconnection.

Solution: Replace the blend door actuator. This can sometimes be a difficult repair, as it often requires disassembling part of the dashboard.

Safety Precautions

Working on AC systems involves handling refrigerants, which can be harmful. Always wear safety glasses and gloves. If you're not comfortable working with refrigerants, it's best to leave the repair to a qualified technician.

Final Thoughts

Diagnosing AC problems in your Nissan Altima can be a challenging but rewarding experience. By systematically following these troubleshooting steps and understanding the underlying principles, you can pinpoint the cause of the issue and restore your AC system to its full cooling potential. Remember to consult your Altima's service manual for specific information and specifications.