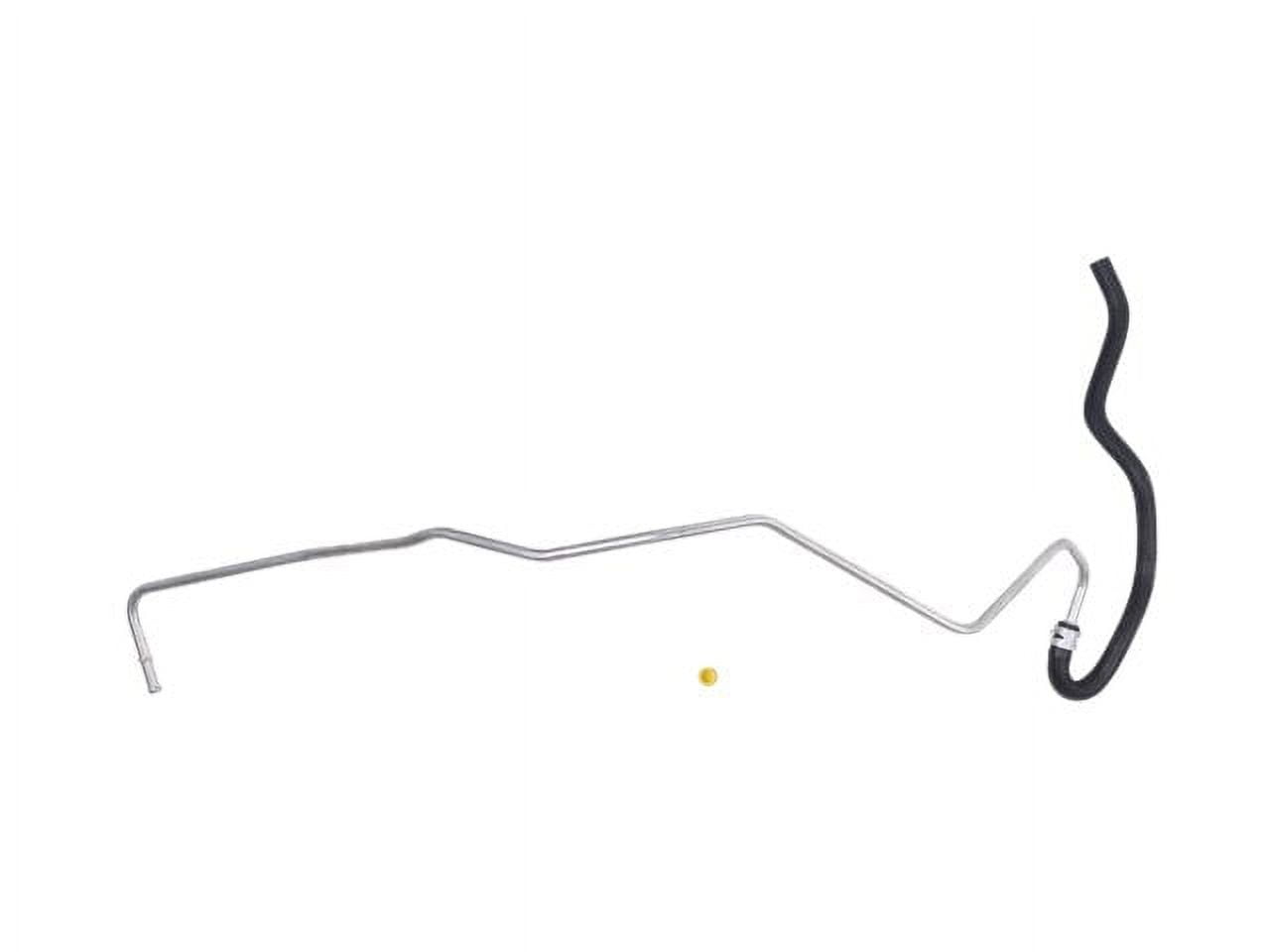

Nissan Altima Power Steering Cooler Tube

The humble power steering cooler tube, a component often overlooked in the grand scheme of automotive engineering, plays a critical role in maintaining the hydraulic power steering system's functionality. While its design may seem rudimentary, the future of mobility, driven by electrification, advanced driver-assistance systems (ADAS), and ever-increasing vehicle complexity, will inevitably impact even this seemingly simple part. Today, let's explore the evolving landscape surrounding the Nissan Altima power steering cooler tube and how technological advancements are reshaping its role and potential.

The Present: A Vital Component Facing Gradual Obsolescence?

Currently, the Nissan Altima relies on a hydraulic power steering system, a technology that has been a mainstay in automobiles for decades. The power steering cooler tube, typically a metal or composite tube with fins, is responsible for dissipating heat generated by the power steering pump and fluid. This heat is a byproduct of the constant hydraulic pressure required to assist the driver in steering, particularly at low speeds and during parking maneuvers. A failing cooler tube can lead to overheating of the power steering fluid, resulting in reduced steering assist, pump damage, and even complete system failure.

However, the automotive industry is rapidly transitioning away from hydraulic power steering systems. Electric power steering (EPS) is becoming increasingly prevalent, offering several advantages over its hydraulic counterpart. EPS systems eliminate the need for a continuously running hydraulic pump, reducing parasitic drag on the engine and improving fuel efficiency. They also offer greater flexibility in steering feel and responsiveness, allowing for customization based on driving conditions and driver preferences. Furthermore, EPS systems are integral to many ADAS features, such as lane keeping assist and automated parking, as they allow the vehicle's computer to directly control the steering.

Therefore, the demand for traditional power steering cooler tubes, like the one found in older Nissan Altima models, is likely to decrease as newer vehicles equipped with EPS become more common. This doesn't mean the technology is entirely obsolete, as a significant number of Altimas with hydraulic power steering remain on the road, requiring maintenance and repairs. Moreover, lessons learned from designing and manufacturing efficient and durable cooler tubes can inform the development of thermal management systems for other automotive components.

The Near Future: Hybridization and Thermal Management

The transition to full electrification is a gradual process. In the interim, hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) are gaining popularity. While some HEVs and PHEVs may still utilize EPS systems, the integration of electric motors and battery packs introduces new thermal management challenges. These components generate significant heat, and maintaining optimal operating temperatures is crucial for performance, efficiency, and longevity.

While the power steering cooler tube itself may not be directly relevant in a fully electric vehicle, the principles of heat dissipation and fluid dynamics remain essential. Engineers are developing sophisticated thermal management systems that utilize advanced coolants, heat exchangers, and electronic controls to regulate the temperature of various components, including the battery pack, electric motor, and power electronics.

Consider the cooling of an electric motor in a high-performance EV. These motors can generate immense amounts of heat during acceleration and high-speed driving. Traditional air cooling may be insufficient, requiring liquid cooling systems that circulate coolant through channels within the motor housing. The design of these cooling channels, the selection of coolant, and the size and efficiency of the heat exchanger are all critical factors in maintaining optimal motor performance and preventing overheating. In a way, the spirit of the power steering cooler tube lives on, adapted and evolved for a new generation of automotive technology. The understanding of fluid dynamics and heat transfer, refined over years of developing components like the cooler tube, informs the design of these advanced thermal management systems.

Challenges in Hybrid and EV Thermal Management

Developing effective thermal management systems for HEVs and EVs presents several challenges:

Complexity: Integrating multiple cooling loops and managing the temperature of various components with different thermal requirements adds complexity to the system.

Efficiency: Maximizing the efficiency of the cooling system is crucial to minimize energy consumption and maximize vehicle range.

Cost: Developing and manufacturing advanced thermal management components can be expensive, impacting the overall cost of the vehicle.

Durability: The cooling system must be durable and reliable, capable of withstanding the harsh operating conditions of the automotive environment.

The Distant Future: Smart Automotive Solutions and Integrated Systems

Looking further ahead, the automotive industry is moving towards a future of smart, connected, and autonomous vehicles. In this future, vehicles will be equipped with a vast array of sensors, actuators, and computer systems that work together to provide a seamless and personalized driving experience. The power steering system, or rather its modern electric equivalent, will be an integral part of this integrated system.

Imagine a scenario where the vehicle's computer constantly monitors various parameters, such as road conditions, driving style, and weather conditions, to optimize the steering feel and responsiveness. The system could automatically adjust the steering assist to provide greater stability in slippery conditions or to enhance maneuverability in tight spaces. Furthermore, the steering system could be integrated with the vehicle's navigation system to provide haptic feedback to the driver, guiding them along the optimal route. For example, slight vibrations in the steering wheel could indicate an upcoming turn or a change in road conditions.

Furthermore, future vehicles might utilize solid-state batteries. These batteries promise higher energy density, faster charging times, and improved safety compared to conventional lithium-ion batteries. However, they also present new thermal management challenges. Solid-state batteries are more sensitive to temperature fluctuations, requiring even more precise and sophisticated thermal control. The cooling system will need to be able to rapidly respond to changes in temperature, preventing overheating or thermal runaway.

Moreover, the concept of "vehicle-to-grid" (V2G) technology could further complicate the thermal management landscape. V2G technology allows electric vehicles to not only draw power from the grid but also to return power to the grid. This bi-directional energy flow can have significant implications for the vehicle's thermal management system. During periods of high demand, the vehicle could discharge its battery to the grid, generating heat that needs to be dissipated. Conversely, during periods of low demand, the vehicle could charge its battery from the grid, potentially requiring cooling to maintain optimal battery temperature.

In this highly integrated future, the line between individual automotive components will blur. The power steering system will no longer be a standalone system but rather a component of a larger, interconnected network. The design and development of this system will require a holistic approach, considering the interactions between various components and the overall impact on vehicle performance, efficiency, and safety.

Conclusion: Embracing the Future of Mobility

The Nissan Altima power steering cooler tube, a seemingly simple component, serves as a reminder of the constant evolution within the automotive industry. While its direct relevance may diminish with the rise of electric vehicles, the underlying principles of heat transfer and fluid dynamics remain critical to the development of advanced thermal management systems. The future of mobility is driven by innovation, and embracing new technologies while learning from the past is essential for success.

The shift from hydraulic to electric power steering, and subsequently to fully integrated smart steering systems, mirrors the broader transformation occurring in the automotive world. As we move towards a future of electrification, autonomy, and connectivity, the challenges are significant, but the opportunities are even greater. We must continue to push the boundaries of engineering and design, developing innovative solutions that are both efficient and sustainable.

The future of mobility is not just about building better cars; it's about creating a better world. A world where transportation is cleaner, safer, and more accessible to all. A world where vehicles are not just machines but intelligent partners that enhance our lives and connect us to each other. The humble power steering cooler tube might fade into the history books, but the ingenuity and dedication that went into its design and manufacture will continue to inspire us as we navigate the exciting road ahead.