Nissan Altima Wheel Bearing Replacement

The Nissan Altima, a stalwart of the mid-size sedan segment, has seen numerous iterations over the years, each with its own subtle variations in design, technology, and, importantly, maintenance needs. One common maintenance item across nearly all Altimas? Wheel bearing replacement. While the fundamental principle remains the same, nuances exist between different models, engine options, and even drivetrain configurations. Let's dive into the nitty-gritty of Altima wheel bearing replacement, focusing on what makes each generation and setup unique.

Understanding the Basics: What is a Wheel Bearing?

Before we get into the specifics, let’s quickly recap what a wheel bearing actually does. Essentially, it’s a set of steel balls (or rollers) held together by a metal ring, allowing the wheel to rotate smoothly with minimal friction. Over time, these bearings can wear out due to heat, contamination (water, dirt), and simple old age. A failing wheel bearing manifests in several ways: humming or grinding noises that increase with speed, looseness in the steering, uneven tire wear, and even vibrations felt through the floorboards.

Altima Generations: A Bearing Breakdown

We'll focus on the recent Altima generations (since the L31 series), highlighting the key differences relevant to wheel bearing replacement:

3rd Generation (L31; 2002-2006)

This generation marked a significant shift for the Altima, growing considerably in size. Wheel bearing replacement on the L31 is relatively straightforward, often involving a complete hub assembly replacement. This simplifies the process, though it can be slightly more expensive upfront. The 2.5L QR25DE engine was prevalent, and regardless of the engine choice, the front wheel bearings are generally similar.

4th Generation (L32; 2007-2012)

The L32 Altima continued the larger trend, offering both the 2.5L QR25DE and the 3.5L VQ35DE engines. The VQ35DE-equipped models, being more powerful, *could* potentially see slightly accelerated wheel bearing wear due to increased stress. However, the difference is usually negligible. Like the L31, hub assembly replacement is the norm. The 2010-2012 models introduced a facelift with minor styling changes, but the wheel bearing design remained largely unchanged.

5th Generation (L33; 2013-2018)

The L33 Altima brought a more refined design and improved fuel efficiency. Engine options remained similar (2.5L and 3.5L), with the CVT becoming the standard transmission. Again, wheel bearing replacement typically involves the entire hub assembly. Some owners have reported issues with aftermarket hub assemblies failing prematurely, so opting for a reputable brand (e.g., Timken, SKF) is highly recommended.

6th Generation (L34; 2019-Present)

The current generation Altima (L34) is arguably the most technologically advanced, featuring available all-wheel drive (AWD) and a novel variable compression turbo engine (VC-Turbo). This is where things get interesting. The AWD models have a distinctly different rear hub and bearing assembly compared to the front-wheel drive (FWD) versions. Furthermore, the VC-Turbo engine, with its higher power output, may contribute to increased stress on the front wheel bearings, particularly under aggressive driving conditions.

Spec Table: Key Differences by Generation

| Generation | Years | Typical Replacement Method | AWD Availability | VC-Turbo Availability | Notes |

|---|---|---|---|---|---|

| L31 | 2002-2006 | Hub Assembly | No | No | Relatively straightforward replacement. |

| L32 | 2007-2012 | Hub Assembly | No | No | VQ35DE might accelerate wear. |

| L33 | 2013-2018 | Hub Assembly | No | No | Use reputable aftermarket brands. |

| L34 | 2019-Present | Hub Assembly (FWD & AWD) | Yes | Yes | AWD has unique rear assembly; VC-Turbo *may* increase front bearing stress. |

FWD vs. AWD: A Critical Distinction (L34)

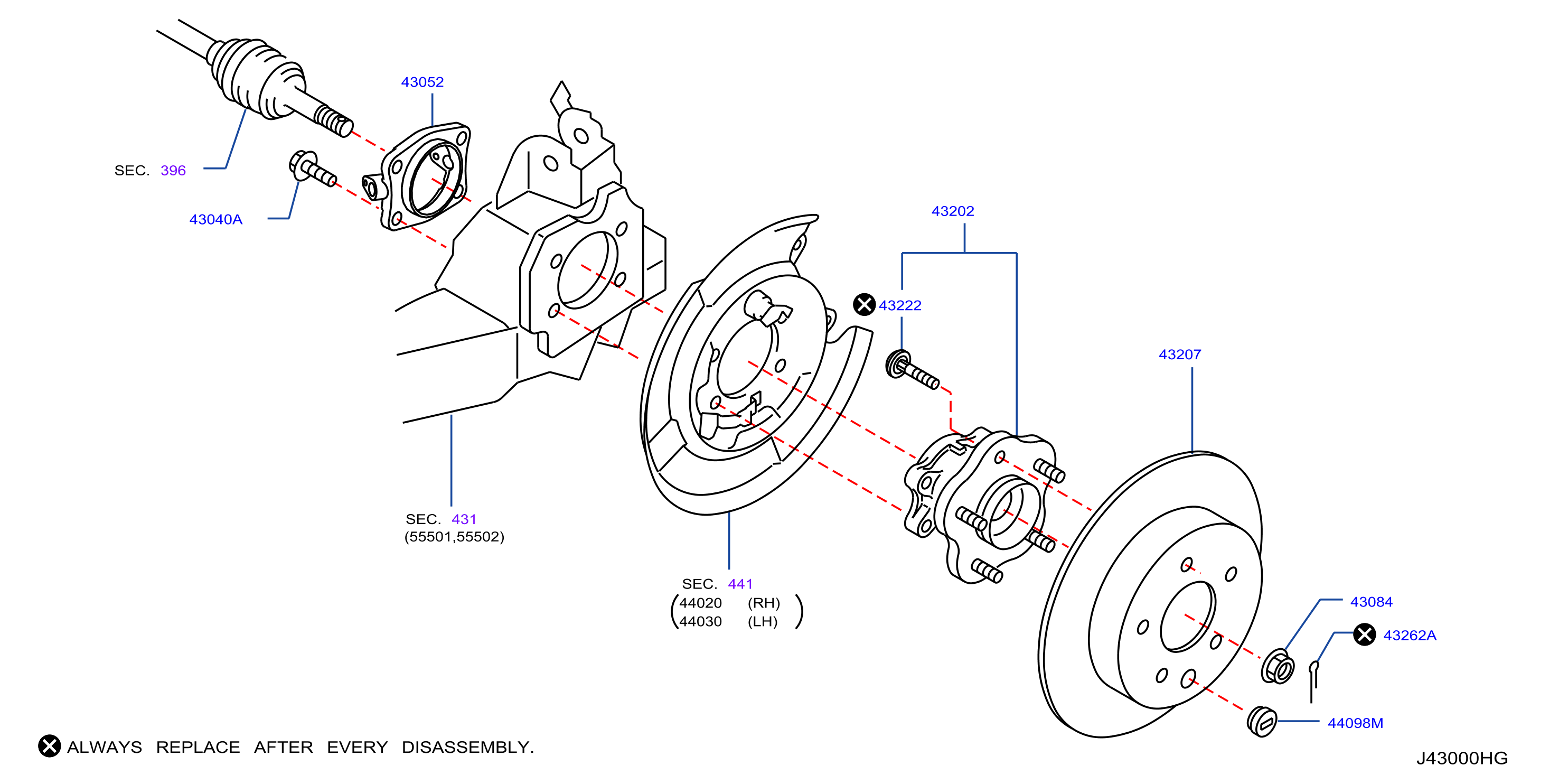

For the L34 Altima, the presence of AWD significantly alters the rear wheel bearing replacement procedure. The rear hub assembly is different, and the process involves additional steps related to the rear differential and suspension components. If you own an AWD L34, ensure you source the correct parts and follow the manufacturer's instructions meticulously. A mistake here could lead to serious mechanical issues.

Engine Options: Does Power Matter?

While the 2.5L engine is known for its reliability and fuel efficiency, the 3.5L V6 (VQ35DE) and the VC-Turbo engine offer a noticeable power boost. Theoretically, this increased power could lead to accelerated wear on the wheel bearings, especially under hard acceleration and cornering. However, in real-world driving, the difference is often marginal unless the vehicle is consistently driven aggressively. Remember, driving habits play a much larger role than the engine alone.

DIY vs. Professional Installation

Replacing a wheel bearing on an Altima can range from a relatively simple DIY job (especially on earlier models with hub assembly replacements) to a more complex undertaking requiring specialized tools and expertise. Here's a quick breakdown:

- DIY (Hub Assembly Replacement): Requires basic hand tools (sockets, wrenches, torque wrench), a jack, and jack stands. Some mechanical aptitude is necessary.

- Professional Installation: Recommended if you lack experience, don't have the necessary tools, or are dealing with a more complex setup (e.g., pressing out and in bearings, AWD models).

Pros and Cons of DIY Wheel Bearing Replacement

- Pros:

- Saves money on labor costs.

- Gain a better understanding of your car's mechanics.

- Sense of accomplishment.

- Cons:

- Requires time, effort, and tools.

- Potential for mistakes that could damage other components.

- Risk of injury if not performed safely.

Real-World Driving Impressions: Spotting a Failing Bearing

Beyond the technical details, let's talk about the *feel* of a failing wheel bearing. Most commonly, you'll hear a humming or grinding noise that gets louder as your speed increases. This noise might change or disappear when you turn the steering wheel, as the load shifts on the bearings. Vibrations, particularly felt through the floorboard or steering wheel, are another telltale sign. Don't ignore these symptoms! A neglected wheel bearing can eventually seize, causing a wheel to lock up, which could lead to a loss of control.

Aftermarket vs. OEM: A Quick Word

When it comes to replacement parts, you'll face the choice between aftermarket and Original Equipment Manufacturer (OEM) components. OEM parts are generally more expensive but offer guaranteed compatibility and quality. Aftermarket parts can be more affordable, but quality can vary significantly. As mentioned earlier, when choosing aftermarket hub assemblies, stick with reputable brands to avoid premature failure.

Torque Specs: Don't Skimp!

Regardless of whether you're tackling a DIY replacement or having a professional do the job, *always* adhere to the manufacturer's specified torque specifications for all fasteners. Overtightening can damage the bearings or other components, while undertightening can lead to loosening and failure. A torque wrench is an essential tool for this task.

A Parting Thought: The VC-Turbo Debate

Here's where things get contentious! Do you think the VC-Turbo engine in the L34 Altima *really* puts significantly more stress on the front wheel bearings compared to the naturally aspirated engines? Or is it more about driving style and maintenance habits? Let the debate begin!