Nissan Cvt Transmission Filter Location

Continuous Variable Transmissions (CVTs) have become increasingly prevalent in modern vehicles, particularly those from Nissan. While offering advantages in fuel efficiency and smoothness, their maintenance and reliability are often subjects of concern among automotive professionals. A critical aspect of CVT maintenance is understanding the location and function of the transmission filter. This article provides an in-depth look at the Nissan CVT transmission filter location, technical specifications, engineering choices, real-world performance implications, and a comparison with alternative designs.

Nissan CVT Filter Location and Types

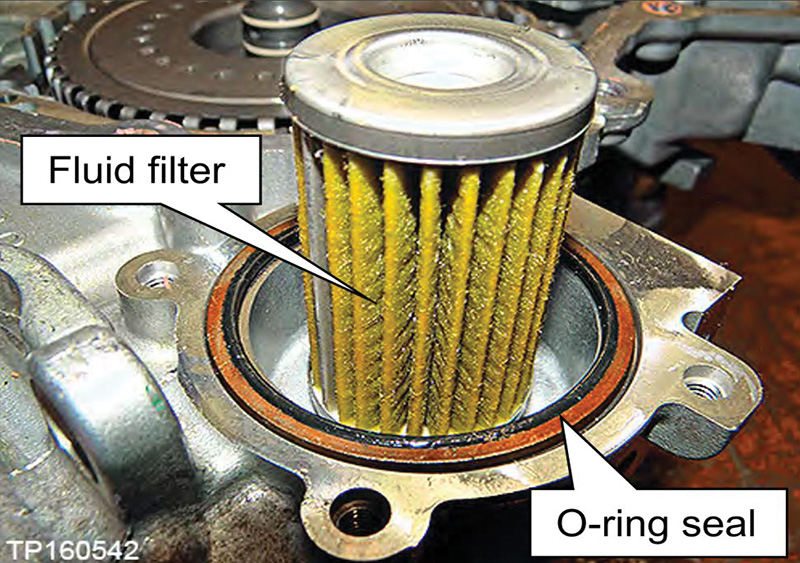

Nissan CVTs generally feature two types of filters: an internal filter and an external filter (also sometimes referred to as an in-line filter). The location of these filters varies depending on the specific CVT model. It's crucial to consult the vehicle's service manual or a reliable parts database (like those offered by major aftermarket suppliers) for the precise location for a given year and model. Generally, the internal filter is located inside the transmission pan and requires removing the pan for access. This filter typically strains larger debris and contaminants that may have found their way into the transmission fluid. The external filter, if present, is usually located in one of the transmission cooler lines, either near the radiator or the transmission itself. This location allows for easier access and replacement.

Technical specifications for these filters often include micron ratings, flow rates, and material composition. Micron ratings indicate the size of particles the filter can capture, with lower numbers indicating finer filtration. Flow rates are important for ensuring adequate fluid circulation within the transmission, especially at higher engine speeds and loads. The filter media is typically made of paper, synthetic fibers, or a combination thereof, with synthetic media generally offering superior filtration and longevity.

Engineering Choices and Rationales

The dual-filter approach reflects a calculated engineering decision. The internal filter, being more robust and less frequently replaced, serves as a primary barrier against larger particles generated from normal wear and tear within the CVT. The external filter, being more accessible, acts as a secondary line of defense, capturing finer contaminants that may have bypassed the internal filter. This two-stage filtration system is designed to maximize fluid cleanliness and extend the lifespan of the CVT components.

Nissan's engineering team selects filter materials based on several factors: filtration efficiency, fluid compatibility, resistance to degradation from heat and pressure, and cost. The aim is to strike a balance between optimal performance and affordability. The choice between an internal-only or a dual-filter system often depends on the CVT model's design complexity, intended application, and performance targets. More robust CVTs, designed for heavier vehicles or higher torque applications, may benefit from the added protection of an external filter.

Real-World Performance and Implications

A clean and properly functioning CVT filter is essential for maintaining optimal transmission performance. A clogged or damaged filter can restrict fluid flow, leading to several detrimental consequences:

- Reduced fluid pressure: Insufficient fluid pressure can compromise the clamping force on the CVT's belt or chain, leading to slippage and decreased efficiency.

- Overheating: Restricted fluid flow reduces the transmission's ability to dissipate heat, potentially causing overheating and accelerated wear of internal components.

- Increased wear and tear: Contaminants circulating in the fluid can act as abrasives, accelerating wear on critical components such as the belt/chain, pulleys, and valve body.

- Shifting problems: Erratic or delayed shifting can occur due to inadequate fluid pressure and improper valve body operation.

- Complete transmission failure: In severe cases, a neglected filter can lead to catastrophic transmission failure, requiring costly repairs or replacement.

Real-world observations often reveal that CVTs with neglected filter maintenance exhibit significantly shorter lifespans and more frequent repairs. Mechanics frequently report finding excessive debris and sludge in transmissions with overdue filter replacements, underscoring the importance of adhering to the manufacturer's recommended service intervals.

Proper filter maintenance can dramatically extend the life of a CVT, reducing the likelihood of costly repairs.

Comparison with Alternatives

Traditional automatic transmissions typically use a single internal filter located within the transmission pan. While some higher-performance automatic transmissions may incorporate an external filter in addition to the internal filter, this is less common than in Nissan CVTs. The main difference lies in the criticality of fluid cleanliness in CVTs. CVTs are more sensitive to fluid contamination due to the precise tolerances and complex control systems involved in their operation.

Pros of Nissan's CVT filter approach:

- Enhanced fluid cleanliness: The dual-filter system provides superior filtration compared to single-filter designs, reducing the risk of contamination-related problems.

- Extended component lifespan: By maintaining cleaner fluid, the filters help prolong the life of critical CVT components.

- Relatively easy external filter replacement (if equipped): The external filter's location allows for quick and convenient replacement, encouraging more frequent maintenance.

Cons:

- Complexity: The dual-filter system adds complexity to the transmission design.

- Cost: Replacing two filters can be more expensive than replacing a single filter.

- Internal filter accessibility: Replacing the internal filter requires removing the transmission pan, which can be a more involved and time-consuming process.

Reliability Aspects and Maintenance Tips

The long-term reliability of a Nissan CVT is heavily influenced by proper maintenance, with filter replacement being a key component. Nissan typically recommends replacing the CVT fluid and filters every 30,000 to 60,000 miles, depending on driving conditions and the specific CVT model. It is crucial to adhere to these recommended service intervals to maintain optimal performance and prevent premature failure.

Maintenance tips:

- Use only genuine Nissan CVT fluid or a high-quality aftermarket fluid that meets Nissan's specifications (e.g., NS-2, NS-3, or NS-CVT). Using the wrong fluid can damage the transmission.

- Replace both the internal and external filters (if equipped) simultaneously during fluid changes.

- Inspect the transmission pan and magnets for debris and metal shavings during internal filter replacement. This can provide valuable insights into the transmission's condition.

- Use a new transmission pan gasket when reinstalling the pan to prevent leaks.

- Properly torque all fasteners to the manufacturer's specifications.

- Consider a transmission cooler for vehicles subjected to heavy towing or frequent stop-and-go driving. This can help reduce fluid temperatures and extend the life of the transmission.

Future Trends

The automotive industry is undergoing a rapid transformation, with electric vehicles (EVs) and hybrid vehicles becoming increasingly popular. While CVTs are currently less common in EVs due to the electric motor's inherent ability to provide a wide range of torque, they may find applications in hybrid vehicles to optimize fuel efficiency and performance. Future CVTs are likely to incorporate advanced technologies such as improved control systems, lighter and stronger materials, and more efficient lubrication systems. Filter designs may also evolve to incorporate finer filtration and longer service intervals.

Another trend is the increasing use of electronic sensors and diagnostics to monitor transmission health. These systems can provide early warnings of potential problems, allowing for proactive maintenance and preventing costly repairs. Future vehicles may even incorporate self-cleaning or automatically replaceable filters.

Conclusion

Understanding the Nissan CVT transmission filter location, function, and maintenance requirements is crucial for automotive professionals. By adhering to recommended service intervals, using high-quality fluids and filters, and performing thorough inspections, technicians can help ensure the long-term reliability and performance of these transmissions. As the automotive industry continues to evolve, staying abreast of the latest technologies and maintenance practices will be essential for providing effective and efficient service to customers. The shift towards electric and hybrid vehicles may alter the landscape of transmission technology, but the principles of fluid cleanliness and preventative maintenance will remain paramount.