Nissan Frontier Timing Chain Replacement

The Nissan Frontier, particularly models equipped with the VQ40DE 4.0L V6 engine, is known for its robust performance and reliability. However, like any engine with an internal combustion process, certain components are subject to wear and eventual failure. One such component is the timing chain. This crucial element synchronizes the crankshaft and camshafts, ensuring precise valve timing and proper engine operation. A failing timing chain can lead to significant engine damage, making its maintenance and timely replacement paramount.

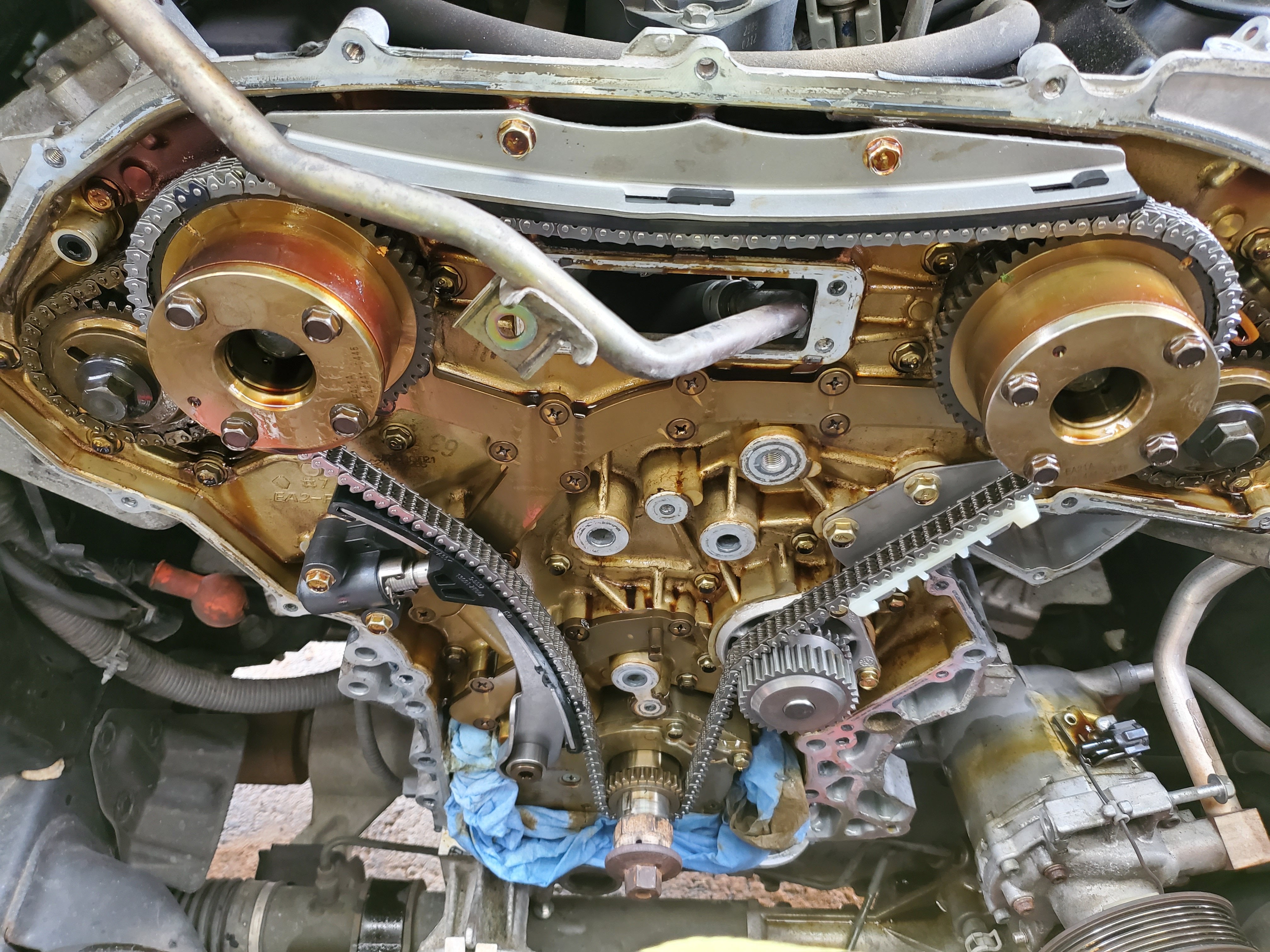

Understanding the Nissan Frontier Timing Chain System

The Frontier's VQ40DE engine utilizes a multi-chain system. This typically consists of a primary chain connecting the crankshaft to the jackshaft, and then secondary chains connecting the jackshaft to each of the camshafts. This design allows for precise valve control and contributes to the engine's overall power output. Understanding the components involved is critical for a successful replacement. These include:

- Timing Chains: The heart of the system, responsible for the mechanical link between the crankshaft and camshafts.

- Timing Chain Tensioners: Hydraulically or mechanically driven, tensioners maintain proper chain tension, preventing slack and potential skipping.

- Timing Chain Guides: These plastic or metal guides direct the chain's path and prevent excessive wear.

- Sprockets: Attached to the crankshaft, jackshaft, and camshafts, the sprockets provide the interface for the timing chains.

- Oil Pump Chain and Sprocket: The oil pump is chain driven, and this chain should also be inspected.

Failure of any of these components can compromise the entire system. Due to their interconnected nature, when replacing the timing chain, it is highly recommended to replace the tensioners, guides, and sprockets as well.

Symptoms of a Failing Timing Chain

Recognizing the signs of a worn or failing timing chain is crucial to preventing catastrophic engine damage. Some common symptoms include:

- Rattling Noise from the Engine: Often most noticeable at startup or idle, this noise is a telltale sign of chain slack caused by wear or faulty tensioners.

- Check Engine Light: A stretched timing chain can cause camshaft and crankshaft timing to be out of sync, triggering a P0011, P0012, P0016, P0017 or similar diagnostic trouble code (DTC). These codes indicate a misalignment between the camshaft and crankshaft positions.

- Engine Misfires: Incorrect valve timing can lead to misfires, resulting in rough idling and decreased engine performance.

- Loss of Power: A stretched or skipping timing chain can significantly reduce engine power and acceleration.

- Hard Starting: Difficulties starting the engine can also be a symptom of timing chain issues.

- Engine Stalling: In severe cases, a failing timing chain can cause the engine to stall completely.

If you experience any of these symptoms, it is imperative to have your Frontier inspected by a qualified mechanic as soon as possible. Ignoring these signs can lead to complete engine failure, resulting in much higher repair costs.

Tools and Materials Required

Replacing a timing chain is a complex procedure that requires specialized tools and a thorough understanding of engine mechanics. If you are not comfortable performing this repair yourself, it is best left to a professional. However, for those with the necessary skills and experience, here's a list of essential tools and materials:

- New Timing Chain Kit: Including the timing chains, tensioners, guides, and sprockets. Always use a reputable brand for quality and reliability.

- Nissan Frontier Service Manual: This provides detailed instructions and torque specifications specific to your vehicle's year and model.

- Timing Chain Alignment Tools: Essential for properly aligning the camshafts and crankshaft during installation.

- Socket Set and Wrenches: Metric sockets and wrenches of various sizes are needed to remove and install engine components.

- Torque Wrench: Crucial for tightening bolts to the correct specifications, preventing damage and ensuring proper assembly.

- Piston Stop Tool: To keep the engine from rotating while loosening or tightening the crankshaft pulley bolt.

- Crankshaft Pulley Holder: Used to hold the crankshaft pulley in place while loosening or tightening the bolt.

- Harmonic Balancer Puller: Required to remove the harmonic balancer from the crankshaft.

- Engine Hoist: For supporting the engine during the process if needed.

- Penetrating Oil: To loosen stubborn bolts and nuts.

- Gaskets and Seals: New gaskets and seals are necessary to prevent leaks after reassembly.

- Engine Oil and Filter: Replace the engine oil and filter after completing the repair.

- Coolant: To refill the cooling system after draining it.

- Clean Rags and Parts Cleaner: For cleaning engine components.

Step-by-Step Timing Chain Replacement Procedure (Overview)

This is a general overview of the timing chain replacement procedure. Consult your Nissan Frontier service manual for specific instructions and torque specifications for your vehicle.

- Preparation: Disconnect the battery, drain the coolant and engine oil, and remove any components obstructing access to the timing chain cover (e.g., radiator, fan shroud, belts, hoses).

- Disassembly: Remove the serpentine belt, crankshaft pulley, and timing chain cover. Carefully inspect all components for wear or damage.

- Timing Mark Alignment: Rotate the engine until the timing marks on the crankshaft and camshaft sprockets are aligned according to the service manual. This is critical for proper engine timing.

- Timing Chain Removal: Carefully remove the old timing chains, tensioners, and guides.

- Component Inspection: Inspect the oil pump chain and sprocket. Consider replacing these components too for maximum reliability.

- Installation: Install the new timing chains, tensioners, and guides, ensuring they are properly seated and aligned with the timing marks. Use the alignment tools to maintain the correct camshaft and crankshaft positions.

- Tensioner Activation: Activate the timing chain tensioners according to the service manual.

- Verification: Double-check the timing mark alignment and rotate the engine by hand to ensure smooth operation and no interference.

- Reassembly: Install the timing chain cover, crankshaft pulley, serpentine belt, and other removed components. Use new gaskets and seals where necessary.

- Fluid Refill: Refill the coolant and engine oil to the proper levels.

- Startup and Testing: Reconnect the battery and start the engine. Listen for any unusual noises and check for leaks. Monitor the engine's performance and address any issues that arise.

Important Note: Incorrect timing can lead to severe engine damage. If you are not confident in your ability to perform this repair accurately, seek professional assistance.

Common Mistakes to Avoid

Several common mistakes can occur during timing chain replacement, leading to complications and potential engine damage. Awareness of these pitfalls can help ensure a successful repair:

- Incorrect Timing Mark Alignment: Failing to properly align the timing marks is the most common cause of timing chain-related problems after replacement. Double-check the alignment multiple times before reassembling the engine.

- Reusing Old Components: Reusing old tensioners, guides, or sprockets can compromise the integrity of the new timing chain system. Replace all components in the timing chain kit for optimal performance and longevity.

- Improper Tensioner Installation: Incorrectly installing or activating the timing chain tensioners can lead to chain slack and premature wear. Follow the service manual instructions carefully.

- Forgetting to Lubricate: Failing to lubricate the timing chains, sprockets, and guides during installation can cause friction and premature wear. Apply engine oil to all components before assembly.

- Using Incorrect Torque Specifications: Over-tightening or under-tightening bolts can damage components and compromise the assembly. Use a torque wrench and follow the service manual specifications.

Preventative Maintenance

While timing chain replacement is an inevitable maintenance item, several steps can be taken to extend its lifespan and prevent premature failure:

- Regular Oil Changes: Using high-quality engine oil and adhering to the recommended oil change intervals is crucial for lubricating the timing chain and tensioners.

- Using the Correct Oil Viscosity: Consult your owner's manual for the proper oil viscosity for your climate and driving conditions.

- Avoiding Excessive Engine Revving: Excessive engine revving can put undue stress on the timing chain and other engine components.

- Addressing Oil Leaks Promptly: Oil leaks can lead to low oil levels and reduced lubrication, accelerating timing chain wear.

- Regular Inspections: Have your mechanic inspect the timing chain system during routine maintenance to identify potential issues early on.

Conclusion

The timing chain is a critical component of the Nissan Frontier's engine, and its proper function is essential for reliable performance. Recognizing the symptoms of a failing timing chain, using the correct tools and procedures, and performing preventative maintenance can help ensure a long and trouble-free lifespan. While timing chain replacement can be a complex undertaking, understanding the system and its components is crucial for both DIY enthusiasts and professional mechanics alike. Always consult the factory service manual and prioritize accuracy and precision during the repair process. Addressing timing chain issues promptly and effectively will help keep your Nissan Frontier running smoothly for years to come.