Nissan Juke Timing Chain Replacement

The Nissan Juke, with its distinctive styling and peppy engines, has carved a unique niche in the compact crossover market. While generally reliable, like all vehicles, certain components are subject to wear and tear. The timing chain, a critical element synchronizing the crankshaft and camshaft(s), is one such component that may require replacement over the Juke's lifespan. This article provides a comprehensive guide to understanding, diagnosing, and addressing timing chain issues in the Nissan Juke, aimed at enthusiasts, owners, and professionals alike.

Understanding the Nissan Juke Timing Chain System

Unlike timing belts, which are typically made of reinforced rubber, timing chains are constructed from metal links, offering significantly greater durability. However, even the sturdiest chain can stretch or experience wear on its guides and tensioners over time. The Nissan Juke utilizes a timing chain system in most of its engine variants, including the popular HR16DE 1.6-liter naturally aspirated engine and the turbocharged MR16DDT 1.6-liter engine. The chain's job is to ensure the precise opening and closing of engine valves relative to piston position, a process essential for efficient combustion.

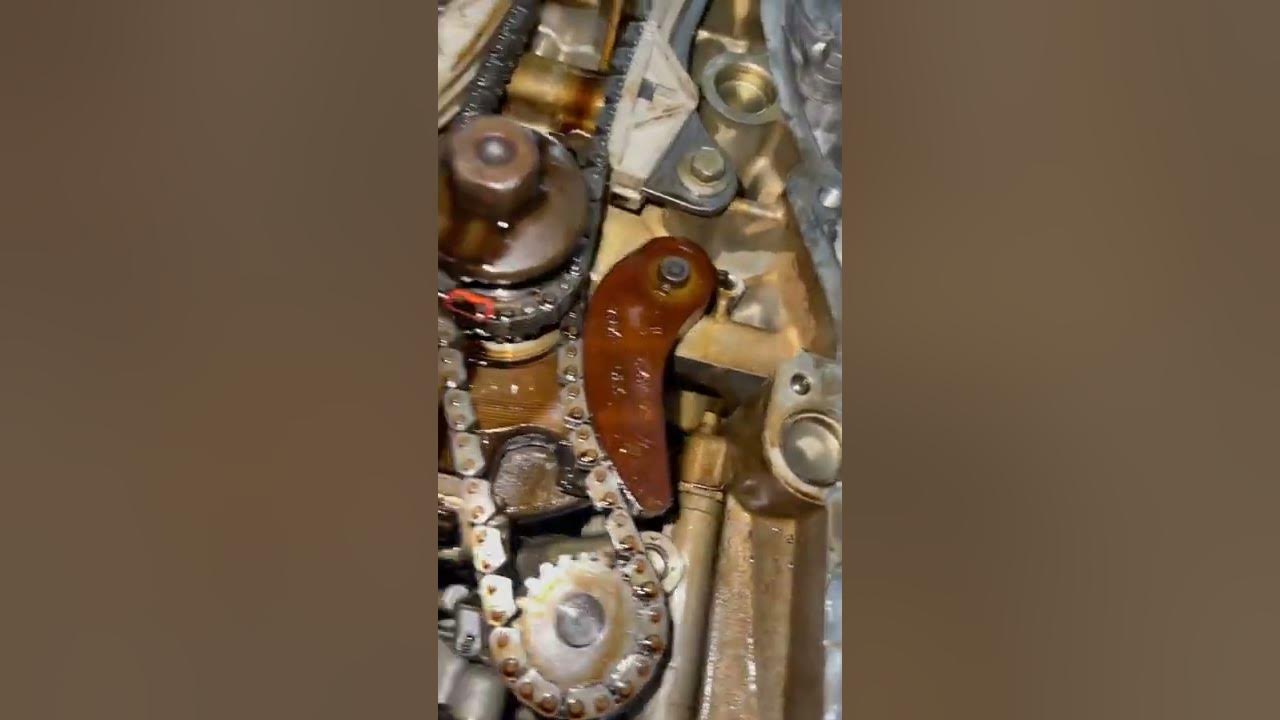

The timing chain system isn't just the chain itself. It comprises several crucial parts:

- Timing Chain: The main component transmitting rotational force.

- Timing Chain Guides: Plastic or metal guides that direct the chain's path, preventing excessive vibration and ensuring smooth operation.

- Timing Chain Tensioner: A spring-loaded or hydraulically actuated device that maintains proper chain tension, preventing slack and potential skipping.

- Sprockets: Gears mounted on the crankshaft and camshaft(s) that the timing chain engages with.

Symptoms of a Failing Nissan Juke Timing Chain

Recognizing the early warning signs of a timing chain issue can prevent catastrophic engine damage. Here are some common symptoms:

- Rattling Noise: A rattling or whining sound coming from the engine, particularly during startup or idle, is a classic indicator of a stretched or worn timing chain. This noise often intensifies with engine speed.

- Check Engine Light (CEL): The engine control unit (ECU) may trigger the CEL with codes related to camshaft/crankshaft correlation. Common codes include P0011, P0012, P0016, P0017, P000A, and P000B. These codes suggest a mismatch between the positions of the crankshaft and camshaft(s), often due to timing chain stretch.

- Rough Idle: A stretched timing chain can disrupt valve timing, leading to an unstable and rough idle.

- Loss of Power: Inaccurate valve timing reduces engine efficiency, resulting in a noticeable decrease in power, especially during acceleration.

- Poor Fuel Economy: Inefficient combustion caused by improper valve timing can lead to reduced fuel economy.

- Engine Misfires: Severely stretched or damaged timing chains can cause engine misfires, triggering additional diagnostic trouble codes.

- Engine Stalling: In extreme cases, a skipping or broken timing chain can cause the engine to stall completely.

It's crucial to address these symptoms promptly. Ignoring them can lead to more severe engine damage, potentially requiring a complete engine rebuild or replacement.

Diagnosing Timing Chain Issues

A thorough diagnosis is essential before embarking on a timing chain replacement. Here's a step-by-step approach:

- Visual Inspection: Carefully inspect the engine for any visible signs of oil leaks, damaged components, or unusual wear.

- Listen for Noises: Use a stethoscope or a long screwdriver to pinpoint the source of any unusual noises. Pay particular attention to the timing chain cover area.

- OBD-II Scan: Use an OBD-II scanner to retrieve any diagnostic trouble codes (DTCs) stored in the ECU. Record all codes and research their potential causes.

- Timing Chain Tensioner Inspection: If accessible, inspect the timing chain tensioner. An excessively extended tensioner rod indicates significant chain stretch. Some tensioners have marks indicating the maximum permissible extension.

- Timing Check: Verify the valve timing using specialized tools and the manufacturer's specifications. This involves aligning timing marks on the crankshaft and camshaft sprockets. Any deviation from the specified alignment confirms a timing chain issue.

- Compression Test: A compression test can reveal potential valve damage resulting from timing chain issues. Low compression in one or more cylinders may indicate bent valves.

Nissan Juke Timing Chain Replacement Procedure

Important Safety Note: Timing chain replacement is a complex procedure that requires specialized tools and expertise. If you are not comfortable performing this repair yourself, it is highly recommended to seek the assistance of a qualified mechanic. Disconnecting the battery is crucial for safety.

Here's a general overview of the timing chain replacement procedure for a Nissan Juke (specific steps may vary depending on the engine model):

- Preparation: Gather all necessary tools, including a timing chain kit (which typically includes the chain, tensioner, guides, and sprockets), sockets, wrenches, torque wrench, crankshaft pulley holder, and engine support. Disconnect the negative battery terminal.

- Component Removal: Remove the accessory drive belts, coolant reservoir, air intake system, and any other components obstructing access to the timing chain cover.

- Drain Coolant and Oil: Drain the engine coolant and engine oil.

- Remove Timing Chain Cover: Carefully remove the timing chain cover. Be mindful of any bolts or fasteners that may be hidden.

- Set Engine to TDC: Rotate the engine manually until the number one piston is at Top Dead Center (TDC) on the compression stroke. Verify that the timing marks on the crankshaft and camshaft sprockets are aligned according to the manufacturer's specifications.

- Secure the Crankshaft: Use a crankshaft pulley holder to prevent the crankshaft from rotating during the timing chain removal and installation process.

- Remove Old Timing Chain: Carefully remove the old timing chain, tensioner, and guides. Inspect the sprockets for wear or damage. Replace them if necessary.

- Install New Timing Chain: Install the new timing chain, tensioner, and guides, ensuring that the timing marks on the chain align correctly with the marks on the sprockets. Follow the manufacturer's instructions for proper chain orientation and tensioner installation.

- Verify Timing: Double-check that the timing marks on the crankshaft and camshaft sprockets are still aligned correctly. Rotate the engine manually several times and re-verify the timing.

- Reassemble: Reinstall the timing chain cover, ensuring that all gaskets and seals are in good condition. Replace any worn or damaged seals.

- Refill Fluids: Refill the engine with fresh engine oil and coolant.

- Reinstall Components: Reinstall all previously removed components, including the accessory drive belts, coolant reservoir, and air intake system.

- Final Checks: Reconnect the negative battery terminal. Start the engine and listen for any unusual noises. Check for leaks. Use an OBD-II scanner to clear any DTCs.

Post-Replacement Procedures and Tips

After replacing the timing chain, it's crucial to perform the following:

- Monitor for Leaks: Closely monitor the engine for any oil or coolant leaks around the timing chain cover.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the engine, particularly during startup and idle.

- Check Engine Performance: Ensure that the engine is running smoothly and efficiently. Monitor fuel economy and performance.

- Oil Change: Consider performing an oil change after a few hundred miles to remove any debris that may have accumulated during the replacement process.

Real-world Example: I once worked on a Juke with the MR16DDT engine that had a severe case of timing chain stretch. The owner had ignored the early warning signs (rattling noise and check engine light) for several months. When I finally replaced the timing chain, the old chain was noticeably longer than the new one. The engine ran significantly smoother and quieter after the repair, and the owner reported a noticeable improvement in fuel economy.

Choosing the Right Timing Chain Kit

Selecting a high-quality timing chain kit is essential for ensuring long-term reliability. Opt for reputable brands known for their durability and performance. Consider kits that include all necessary components, such as the chain, tensioner, guides, and sprockets. Research online reviews and consult with automotive professionals to make an informed decision. Avoid cheap, generic kits, as they may compromise quality and longevity. Some reputable brands include Cloyes, Aisin, and OEM Nissan parts.

Preventative Maintenance

While timing chain replacement is inevitable in some cases, preventative maintenance can significantly extend the lifespan of the timing chain system. Regularly changing the engine oil with the correct viscosity and quality is crucial. Follow the manufacturer's recommended oil change intervals. Address any oil leaks promptly to prevent oil starvation to the timing chain components. Avoid aggressive driving habits that put excessive strain on the engine. These measures can help minimize wear and tear on the timing chain system, delaying the need for replacement.

By understanding the timing chain system, recognizing the warning signs of failure, and following a proper diagnostic and replacement procedure, you can ensure the longevity and performance of your Nissan Juke's engine.