Nissan Juke Timing Chain Replacement Interval

The Nissan Juke, with its distinctive styling and peppy engine, has become a popular choice for many drivers. However, like any vehicle, it requires regular maintenance to ensure optimal performance and longevity. One critical aspect of that maintenance is understanding the timing chain and its potential for replacement.

Understanding the Timing Chain in Your Nissan Juke

Unlike older vehicles that used timing belts, the Nissan Juke predominantly uses a timing chain. The timing chain's primary function is to synchronize the rotation of the crankshaft and camshaft(s). This synchronization is crucial for the engine's valves to open and close at the precise moment, allowing for efficient combustion and smooth operation. Timing chains are generally designed to last longer than timing belts, but they are not immune to wear and tear and can eventually require replacement.

The lifespan of a timing chain is influenced by several factors, including driving habits, maintenance practices, and the quality of engine oil used. Harsh driving conditions, such as frequent hard acceleration and stop-and-go traffic, can accelerate wear on the chain. Neglecting regular oil changes can also contribute to premature failure, as dirty oil can cause increased friction and wear on the chain and its associated components.

Nissan Juke Timing Chain Replacement Interval: The Real Story

Nissan does not provide a specific mileage-based replacement interval for the timing chain in the Juke. Instead, they recommend inspecting the chain and related components for wear or damage during routine maintenance. However, in real-world scenarios, many owners and mechanics suggest proactively inspecting the timing chain system around 100,000 to 150,000 miles. This is especially true for vehicles that have been subjected to demanding driving conditions or have a history of infrequent oil changes.

Why No Official Replacement Interval?

The absence of a mandated replacement interval reflects the design expectation of a timing chain outlasting a timing belt. However, it's crucial to remember that "lifetime" components still require monitoring and potential replacement based on actual condition. Neglecting the timing chain system can lead to catastrophic engine damage if the chain fails.

Troubleshooting Timing Chain Issues: Symptoms and Causes

Identifying timing chain issues early can prevent costly repairs down the road. Here are some common symptoms that may indicate a problem:

- Rattling or Whining Noises: These noises are often most noticeable during cold starts or at idle. A stretched or worn timing chain can create slack, causing it to rattle against the timing cover or other engine components.

- Check Engine Light (CEL): A stretched timing chain can disrupt the engine's timing, triggering various diagnostic trouble codes (DTCs) related to camshaft or crankshaft position sensor correlation. Common codes include P0011, P0012, P0016, P0017, and similar variations.

- Rough Idling: A misaligned timing chain can cause the engine to idle roughly or stall, especially at low speeds. This is because the valves are not opening and closing at the correct times, leading to inefficient combustion.

- Loss of Power: A stretched timing chain can retard the engine's timing, resulting in a noticeable decrease in power and acceleration.

- Increased Fuel Consumption: Inefficient combustion due to improper timing can lead to increased fuel consumption.

- Engine Misfires: Similar to rough idling, misfires can occur when the valves are not timed correctly, leading to incomplete combustion in one or more cylinders.

Common Causes of Timing Chain Problems:

- Lack of Regular Oil Changes: Dirty or contaminated oil can accelerate wear on the timing chain, tensioners, and guides.

- Low Oil Level: Insufficient oil can lead to inadequate lubrication of the timing chain system, causing increased friction and wear.

- Poor Quality Oil: Using the wrong type or grade of oil can also contribute to premature timing chain failure. Always use the oil viscosity recommended by Nissan.

- Aggressive Driving Habits: Frequent hard acceleration and high-RPM driving can put excessive stress on the timing chain.

- Faulty Timing Chain Tensioner: The tensioner maintains proper tension on the timing chain. A faulty tensioner can allow the chain to become loose, leading to rattling and eventual failure.

- Worn Timing Chain Guides: These guides help to keep the timing chain aligned and prevent it from rubbing against other engine components. Worn or broken guides can accelerate chain wear.

Diagnosing and Repairing Timing Chain Issues

If you suspect a timing chain problem, it's crucial to have your vehicle inspected by a qualified mechanic. Here's a breakdown of the diagnostic and repair process:

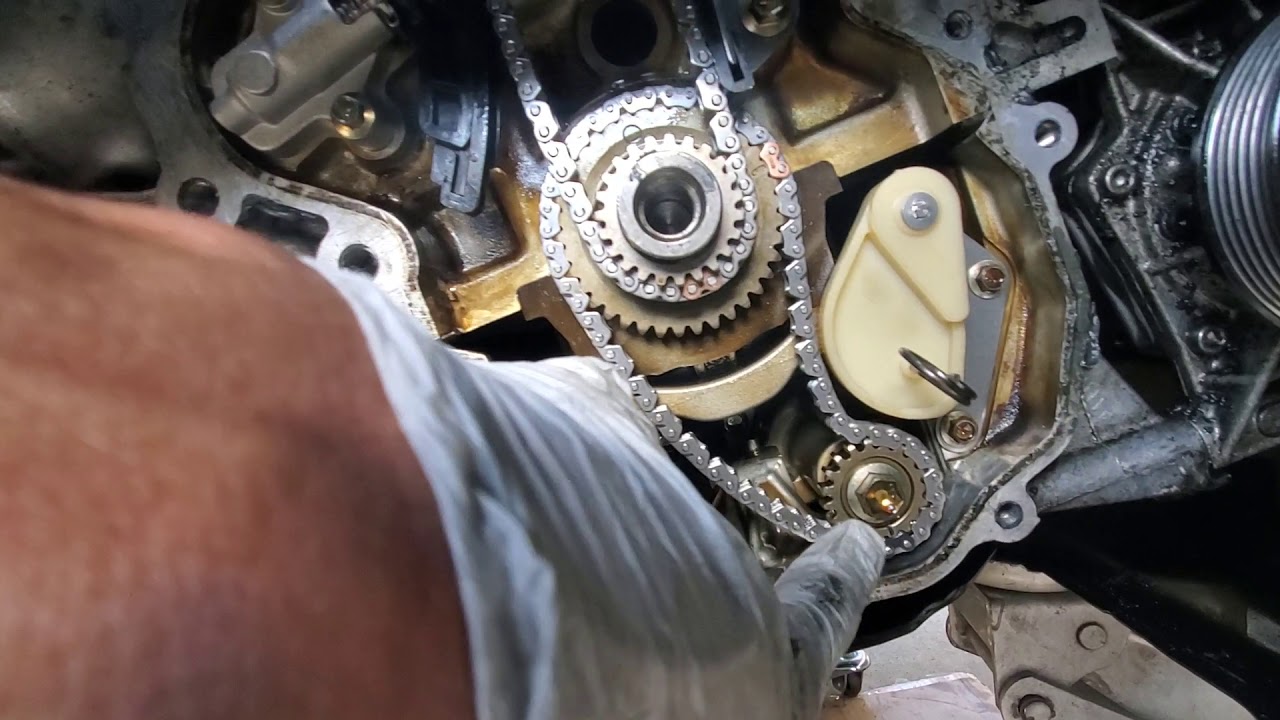

- Visual Inspection: The mechanic will visually inspect the timing chain, tensioner, and guides for signs of wear or damage. This may involve removing the timing cover for a more thorough inspection.

- Diagnostic Trouble Codes (DTCs): The mechanic will scan the engine control unit (ECU) for any DTCs related to the timing chain system. These codes can provide valuable clues about the nature of the problem.

- Mechanical Tests: The mechanic may perform mechanical tests to assess the timing chain's tension and alignment. This could involve using specialized tools to measure chain stretch or check the camshaft and crankshaft timing angles.

Repair Options:

If the timing chain is found to be stretched or worn, replacement is the recommended course of action. A complete timing chain replacement typically includes the following components:

- Timing Chain

- Timing Chain Tensioner

- Timing Chain Guides

- Crankshaft Sprocket

- Camshaft Sprocket(s)

- Water Pump (often recommended, as it's frequently accessed during the timing chain replacement)

- Seals and Gaskets

It's essential to replace all of these components as a set to ensure proper operation and prevent premature failure of the new timing chain. Using high-quality parts from reputable manufacturers is also crucial for long-term reliability.

Example: Consider a 2012 Nissan Juke with 120,000 miles. The owner reports a rattling noise during cold starts and a noticeable loss of power. A mechanic diagnoses a stretched timing chain and recommends a complete timing chain replacement kit. By replacing all the components simultaneously, the owner can ensure that the engine timing is properly restored and prevent future issues.

Cost Considerations:

Timing chain replacement can be a relatively expensive repair, as it involves significant labor. The cost will vary depending on the vehicle model, the extent of the damage, and the labor rates in your area. However, neglecting a worn timing chain can lead to even more costly engine damage, such as bent valves or a damaged cylinder head. Therefore, it's best to address timing chain issues proactively.

Real-World Issues and Examples

Many Nissan Juke owners have reported timing chain issues, particularly in earlier model years. These reports often involve rattling noises, check engine lights, and performance problems. Some owners have found that using high-quality synthetic oil and following a more frequent oil change schedule (e.g., every 5,000 miles) can help to extend the life of the timing chain. Others have opted to install aftermarket timing chain tensioners or guides that are designed to be more durable than the OEM components.

Comparison with Other Models:

The Nissan Juke shares its engine with other Nissan and Renault models, such as the Nissan Versa, Sentra, and some Renault Clios. Therefore, these models may also be susceptible to similar timing chain issues. It's important to research the specific maintenance requirements and common problems associated with your vehicle's engine. For example, the Nissan Altima with the 2.5L engine (QR25DE) has also been known to experience timing chain problems. While the design isn't identical to the Juke's, the underlying issues stemming from oil quality and maintenance are similar.

Example: A mechanic working on a Nissan Sentra with the same engine as the Juke noted that consistent oil changes every 3,000 miles, rather than the manufacturer's suggested interval, significantly reduced the likelihood of timing chain issues. This highlights the importance of proactive maintenance.

Tips for Maintaining Your Nissan Juke's Timing Chain

Here are some practical tips to help keep your Nissan Juke in top condition and prolong the life of its timing chain:

- Follow the Recommended Oil Change Schedule: Adhere to Nissan's recommended oil change intervals or, even better, shorten them slightly, especially if you frequently drive in harsh conditions.

- Use High-Quality Engine Oil: Use the correct type and grade of engine oil as specified in your owner's manual. Synthetic oil is generally recommended for better lubrication and protection.

- Check Oil Levels Regularly: Monitor your oil level regularly and top it off as needed. Low oil levels can lead to increased wear on the timing chain system.

- Avoid Aggressive Driving: Minimize hard acceleration and high-RPM driving, as this can put excessive stress on the timing chain.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from your engine, such as rattling or whining. These noises could indicate a timing chain problem.

- Regular Inspections: Have your mechanic inspect the timing chain and related components during routine maintenance visits.

- Consider an Oil Analysis: Regular oil analysis can reveal early signs of wear or contamination, allowing you to address potential issues before they become major problems.

- Use OEM or High-Quality Replacement Parts: When replacing timing chain components, opt for OEM (Original Equipment Manufacturer) parts or high-quality aftermarket alternatives from reputable brands.

By following these tips, you can help to ensure that your Nissan Juke's engine remains in top condition and that the timing chain lasts as long as possible.

Proactive maintenance and early detection are key to preventing costly repairs and keeping your Nissan Juke running smoothly for years to come.