Nissan Ka24 Torque Settings

The Nissan KA24 engine, a workhorse found in many popular Nissan models like the 240SX (S13 & S14), Altima, and Hardbody pickup, is known for its reliability. However, like any engine, proper maintenance and understanding of torque specifications are critical for its longevity and performance. This article focuses on essential torque settings for the KA24 engine, offering troubleshooting tips and practical solutions for common issues.

Why Torque Settings Matter

Using the correct torque settings is crucial for several reasons. Under-torquing can lead to leaks, loose components, and eventual failure. Over-torquing can stretch or break bolts, strip threads, and damage engine components. Both situations can result in costly repairs. Torque is the rotational force applied to a fastener, and precise application ensures the correct clamping force, distributing stress evenly across the joint.

Essential KA24 Torque Specifications

Here's a breakdown of common torque specifications. Always consult your vehicle's repair manual for specific values, as variations can exist between models and years. Use a calibrated torque wrench for accurate results.

Cylinder Head

The cylinder head bolts are critical. Improper torque can lead to head gasket failure, coolant leaks, and oil leaks. The KA24 typically uses a torque-to-yield (TTY) bolt design, meaning they stretch slightly upon tightening. They should be replaced every time they're removed. Always follow the manufacturer's recommended tightening sequence and use new bolts.

Example procedure:

- Lightly lubricate the threads of the new cylinder head bolts with engine oil.

- Install all bolts finger tight.

- Stage 1: Torque all bolts to 22 ft-lbs (30 Nm) in the proper sequence (typically a spiral pattern starting from the center bolts outwards).

- Stage 2: Torque all bolts to 51 ft-lbs (69 Nm) in the same sequence.

- Stage 3: Turn all bolts an additional 90 degrees (1/4 turn) in the same sequence. This is where the TTY bolts stretch.

Problem: Coolant leaks around the head gasket.

Possible Cause: Improper cylinder head bolt torque. Reusing old bolts can also prevent proper clamping force.

Solution: Replace head gasket and head bolts, following the correct torque procedure. Check the head and block for warpage and have them resurfaced if necessary.

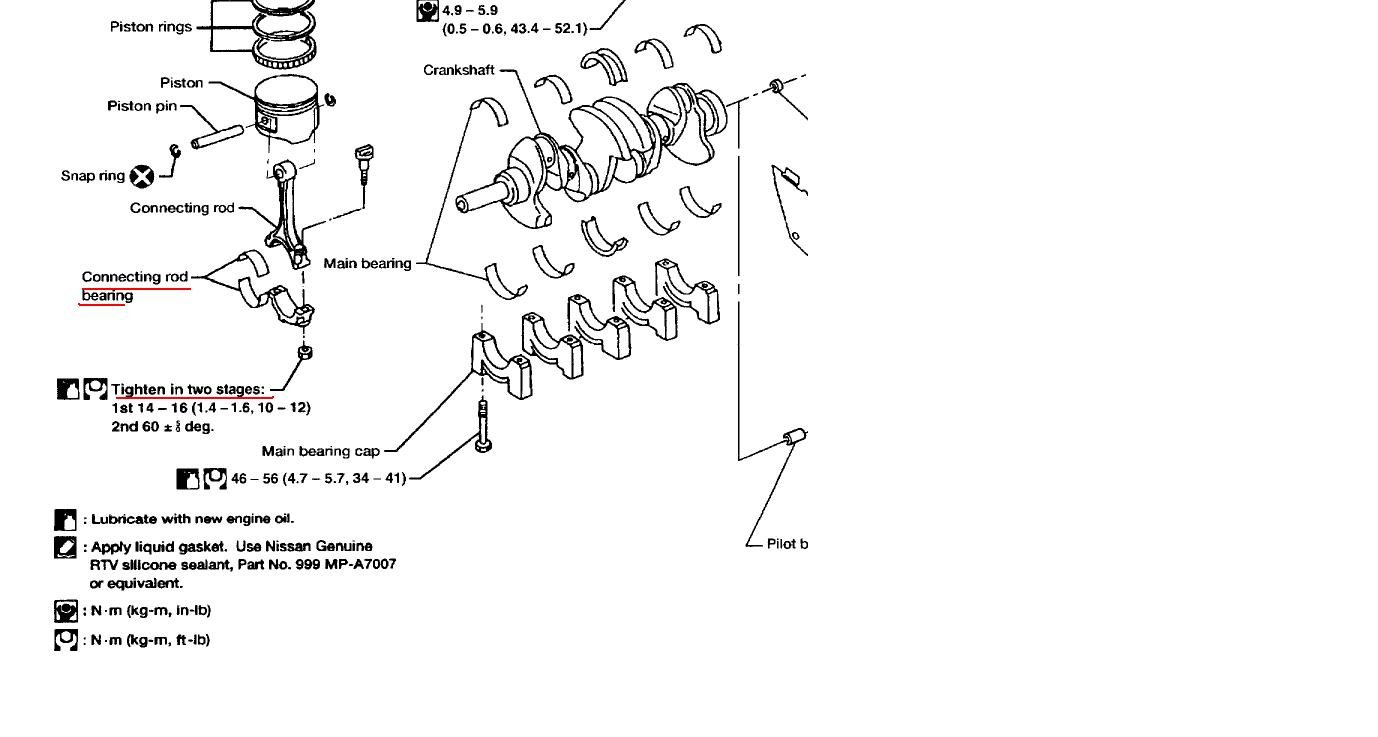

Connecting Rods

Connecting rod bolts hold the connecting rods to the crankshaft. Incorrect torque can lead to rod knock, bearing failure, and potentially catastrophic engine damage. Connecting rod bolts are also frequently TTY and should be replaced when removed.

Example:

- Lubricate the threads and under the bolt heads with engine oil.

- Install connecting rod caps and bolts finger tight.

- Stage 1: Torque all bolts to 15 ft-lbs (20 Nm).

- Stage 2: Turn all bolts an additional 60-90 degrees (check your manual).

Problem: Engine knocking, especially at low RPMs.

Possible Cause: Loose connecting rod bolts causing bearing failure.

Solution: Inspect connecting rod bearings for damage. Replace bearings and bolts, torque to specification. Check crankshaft for damage if bearing failure was significant.

Main Bearing Caps

Main bearing caps secure the crankshaft to the engine block. These are critical for crankshaft support and oil clearance. Again, proper torque is essential to prevent premature bearing wear and crankshaft damage. These are often not TTY, but check your manual.

Example:

- Lubricate threads and under bolt heads.

- Install main bearing caps and bolts finger tight.

- Torque bolts to 47-51 ft-lbs (64-69 Nm) in sequence, typically starting from the center caps and working outwards.

Problem: Low oil pressure, especially when the engine is hot.

Possible Cause: Excessive crankshaft play due to worn main bearings, often caused by improper main bearing cap torque.

Solution: Check main bearing clearances with plastigauge. Replace main bearings and torque main bearing cap bolts to specification. Check crankshaft for wear.

Intake and Exhaust Manifolds

Intake and exhaust manifold bolts are typically lower torque values. Over-tightening can warp the manifolds or strip the threads in the cylinder head. Always use a torque wrench and the correct tightening sequence (usually from the center outwards).

Example:

- Install manifold bolts finger tight.

- Torque bolts to approximately 14-18 ft-lbs (19-24 Nm) in the proper sequence.

Problem: Exhaust leaks or vacuum leaks around the intake manifold.

Possible Cause: Loose or broken manifold bolts, warped manifold due to over-tightening.

Solution: Check manifold for warpage. Replace gaskets and bolts. Torque to specification in the proper sequence.

Spark Plugs

Spark plugs require a specific torque to ensure a good seal and proper heat transfer. Overtightening can damage the spark plug threads in the cylinder head. Consult the spark plug manufacturer's specifications.

Example: Most spark plugs for the KA24DE call for around 18-22 ft-lbs (24-30 Nm), but it varies, so check the spark plug box.

Problem: Difficult to remove spark plugs, stripped threads in the cylinder head.

Possible Cause: Overtightened spark plugs.

Solution: Use a thread chaser to clean the spark plug threads in the cylinder head. If the threads are severely damaged, a thread repair kit (e.g., Heli-Coil) may be necessary.

Oil Pan

The oil pan bolts are crucial for preventing oil leaks. Overtightening can damage the oil pan flange or strip the threads in the engine block. Use a torque wrench and a gasket.

Example: Around 7-9 ft-lbs (9-12 Nm) is typical. These are small bolts, so be careful!

Problem: Oil leaks from the oil pan gasket.

Possible Cause: Over or undertightened oil pan bolts, damaged gasket.

Solution: Replace the oil pan gasket and torque the bolts to specification. Inspect the oil pan flange for damage or warpage.

Troubleshooting Common KA24 Issues

Problem: Engine overheating

Possible Cause: Head gasket failure due to improper cylinder head bolt torque, coolant leaks, or a faulty water pump.

Solution: Pressure test the cooling system to check for leaks. Perform a compression test to check for head gasket leaks. Replace the head gasket and cylinder head bolts if necessary, following the correct torque procedure. Replace the water pump if faulty.

Problem: Engine knocking or rattling

Possible Cause: Loose connecting rod bolts, worn connecting rod bearings, or piston slap.

Solution: Inspect connecting rod bearings for damage. Replace bearings and bolts, torque to specification. Check crankshaft for damage if bearing failure was significant. Piston slap usually requires a full engine rebuild.

Problem: Oil leaks

Possible Cause: Worn or damaged gaskets (valve cover, oil pan, front main seal, rear main seal), loose bolts, or over-tightened bolts causing gasket damage.

Solution: Identify the source of the leak. Replace the gasket and torque the bolts to specification. Inspect sealing surfaces for damage.

Tips for Maintaining Your KA24 Engine

- Regular Oil Changes: Use high-quality engine oil and filters and change them according to the manufacturer's recommendations.

- Coolant System Maintenance: Flush and refill the cooling system every 2-3 years to prevent corrosion and scale buildup.

- Valve Adjustments: The KA24E and early KA24DE engines require periodic valve adjustments. Follow the manufacturer's recommendations for valve clearances.

- Timing Chain Maintenance: While robust, the timing chain can stretch over time. Listen for rattling noises and inspect the timing chain tensioner periodically.

- Use Quality Parts: Always use high-quality replacement parts, especially for critical engine components.

- Proper Torque: Always use a calibrated torque wrench and follow the manufacturer's recommended torque specifications.

By understanding the importance of torque settings and performing regular maintenance, you can keep your Nissan KA24 engine running reliably for years to come. Consult your vehicle's repair manual for specific information and torque specifications.