Nissan Rogue 2021 Brake Pads

The 2021 Nissan Rogue represents a significant redesign for the popular compact SUV, and while much attention is given to its aesthetics and technology, the fundamental components of its safety system, like the brakes, deserve a closer look. This guide will delve into the specifics of the 2021 Rogue's brake pads, exploring their materials, design, function, and the underlying engineering principles that ensure safe and reliable stopping power.

Brake System Overview

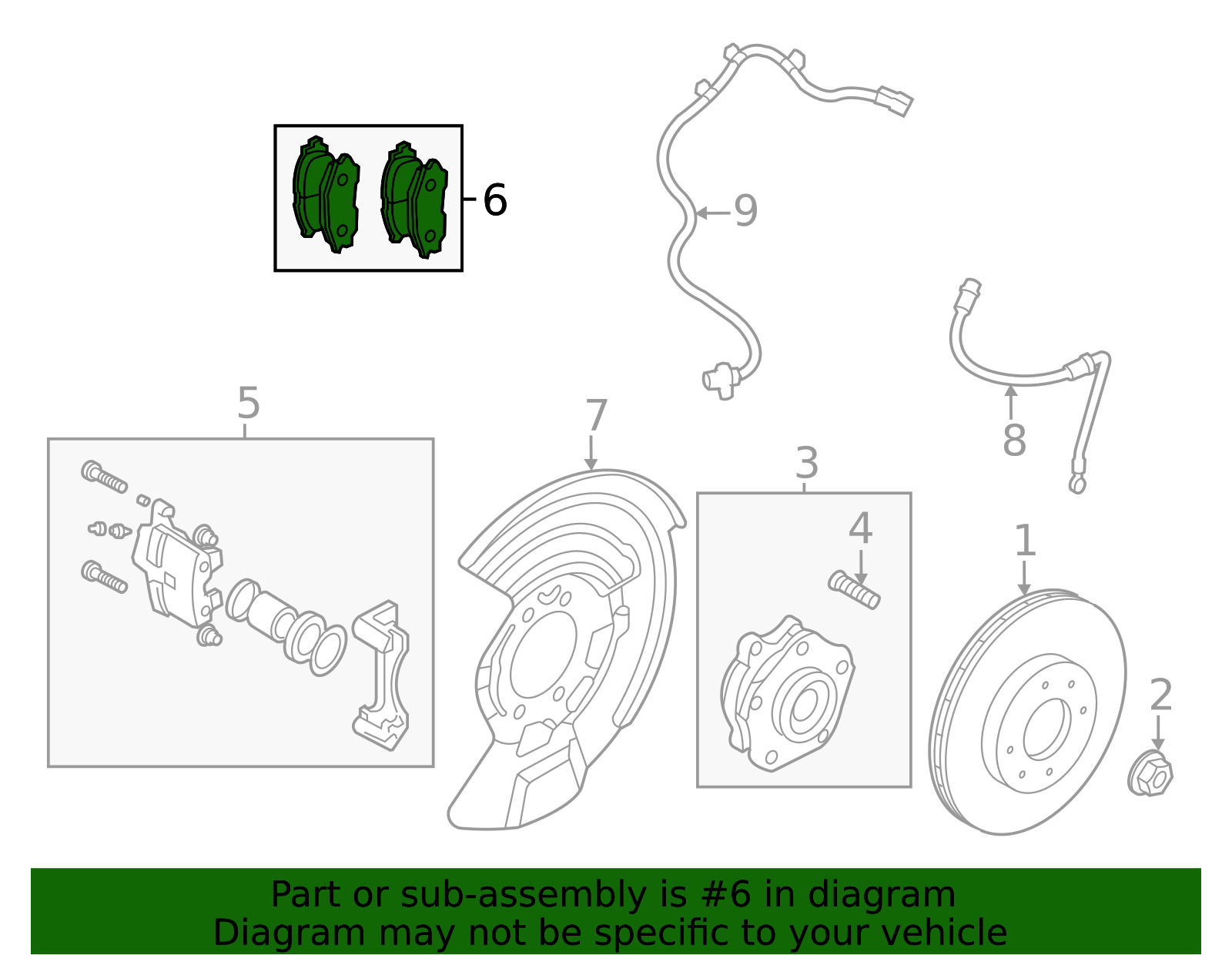

Before diving into the pads themselves, it's crucial to understand the broader context of the braking system. The 2021 Rogue, like most modern vehicles, utilizes a hydraulic braking system. When the driver presses the brake pedal, it activates a master cylinder, which then pushes brake fluid through lines to each wheel. At each wheel resides a caliper, which houses the brake pads. The hydraulic pressure forces the caliper pistons to clamp the brake pads against the brake rotors (also known as discs), creating friction and slowing the vehicle. The key components are therefore the master cylinder, brake lines, calipers, brake pads, and rotors. The efficiency and responsiveness of the entire system depend heavily on the performance of each component, with the brake pads playing a pivotal role.

Brake Pad Composition and Materials

Brake pads are not simply solid blocks of friction material. They are carefully engineered composites designed to balance stopping power, durability, noise reduction, and rotor wear. The materials used in the 2021 Rogue's brake pads are chosen to meet specific performance criteria established by Nissan.

Typically, modern brake pads are categorized into several types based on their composition:

- Organic (Non-Asbestos Organic - NAO): These pads use a blend of fibers, resins, and fillers. They tend to be quieter and produce less rotor wear, but they also wear faster and may not perform as well under high-temperature or heavy-duty braking conditions. While early organic pads contained asbestos, this is now prohibited due to health concerns.

- Semi-Metallic: These pads contain a significant amount of metal (typically 30-70%) mixed with other materials. They offer improved stopping power and heat dissipation compared to organic pads, making them a good choice for general driving conditions. However, they can be noisier and cause more rotor wear.

- Ceramic: Ceramic brake pads use ceramic fibers, fillers, and bonding agents. They provide excellent stopping power, are quiet, and produce very little brake dust. They also tend to be more expensive than other types of pads.

- Low-Metallic NAO: This is a hybrid approach, blending some metallic content into an organic formulation to boost performance without the harshness of full semi-metallic pads. They often represent a good balance of performance, noise, and rotor wear.

It is likely that the 2021 Nissan Rogue utilizes either a low-metallic NAO or a ceramic-enhanced formulation for its brake pads. The exact composition is proprietary information, but these types strike a good balance for everyday driving, providing adequate stopping power, acceptable noise levels, and reasonable rotor life. The backing plate, which is the metal plate to which the friction material is bonded, is typically made of steel. This plate provides structural support and facilitates heat transfer away from the friction material.

Brake Pad Design and Construction

The design of a brake pad goes beyond just the friction material. Several key features contribute to its overall performance:

- Chamfers and Slots: Many brake pads feature chamfers (angled edges) and slots on the friction surface. These are designed to reduce noise and vibration. Chamfers prevent the leading and trailing edges of the pad from grabbing the rotor abruptly, while slots help to vent gases and debris generated during braking, maintaining a clean contact surface.

- Wear Indicators: Brake pads are equipped with wear indicators that alert the driver when the pads need to be replaced. These indicators can be mechanical (a small metal tab that rubs against the rotor, producing a squealing noise) or electronic (a sensor that triggers a warning light on the dashboard). The 2021 Rogue likely uses a combination of both types depending on trim level.

- Anti-Squeal Shims: These are thin layers of material (often rubber or composite) attached to the back of the brake pads. They help to dampen vibrations and reduce brake squeal. The use of these shims is crucial in maintaining a quiet and comfortable driving experience.

- Friction Material Bonding: The friction material is bonded to the backing plate using a high-strength adhesive. This adhesive must be able to withstand high temperatures and shear forces to prevent the friction material from separating from the backing plate.

The overall shape and size of the brake pad are also crucial. The pad must be designed to fit precisely within the caliper and to provide adequate contact area with the rotor. The larger the contact area, the greater the stopping power, but also the greater the potential for heat buildup.

Heat Management

Friction generates significant heat, and brake pads are subjected to extreme temperatures during braking. If the heat is not dissipated effectively, it can lead to brake fade (a reduction in braking performance due to the friction material overheating) and damage to other brake system components. Several design features contribute to heat management:

- Friction Material Composition: Certain materials used in brake pad construction are better at dissipating heat than others. Semi-metallic and ceramic pads, for example, generally offer better heat dissipation than organic pads.

- Ventilation: Some brake rotors are vented, meaning they have internal channels that allow air to flow through them, cooling them down. The 2021 Rogue's front rotors are likely vented, while the rear rotors may be solid, depending on the model.

- Backing Plate Design: The design of the backing plate can also influence heat transfer. Some backing plates have cutouts or other features that improve airflow.

- Brake Fluid: The brake fluid itself plays a role in heat management. Over time, brake fluid can absorb moisture, which lowers its boiling point and makes it more susceptible to boiling under high temperatures. This can lead to brake fade. Regular brake fluid flushes are essential to maintain optimal braking performance.

Failure to manage heat effectively can lead to a phenomenon known as brake fade, where the coefficient of friction between the pads and rotor decreases due to excessive temperature. This results in a reduced braking force for the same pedal effort. Severe brake fade can be a dangerous situation, highlighting the importance of selecting appropriate brake pads and maintaining the braking system properly.

Brake Pad Performance Characteristics

The performance of brake pads is characterized by several key factors:

- Coefficient of Friction (µ): This is a measure of the friction between the brake pad and the rotor. A higher coefficient of friction indicates greater stopping power. However, a higher coefficient of friction can also lead to increased rotor wear.

- Fade Resistance: This is the ability of the brake pad to maintain its stopping power under high-temperature conditions.

- Wear Rate: This is the rate at which the brake pad material wears away during use. A lower wear rate indicates longer pad life.

- Noise Level: Brake pads can generate noise during braking, particularly squealing or grinding sounds. Quiet operation is an important consideration for many drivers.

- Dust Generation: Brake pads produce dust as they wear down. Some types of pads produce more dust than others. Ceramic pads, for example, tend to produce very little dust.

These characteristics are carefully balanced to achieve the desired performance characteristics for the 2021 Rogue. Nissan engineers have selected brake pads that provide adequate stopping power, good fade resistance, acceptable wear rate, and low noise levels for typical driving conditions.

Maintenance and Replacement

Brake pads are a wear item and will eventually need to be replaced. The lifespan of brake pads depends on several factors, including driving habits, road conditions, and the type of brake pads used. As a general rule, brake pads should be inspected regularly, and replaced when they reach a minimum thickness specified by Nissan. Ignoring worn brake pads can lead to damage to the rotors, requiring more expensive repairs.

When replacing brake pads, it is important to use high-quality replacement pads that meet or exceed the original equipment specifications. Using inferior pads can compromise braking performance and safety. It is also recommended to replace the rotors at the same time as the brake pads if the rotors are worn or damaged. The 2021 Rogue's brake pads require periodic inspection, generally during routine maintenance appointments. A visual inspection of the pad thickness can provide an indication of remaining life. Additionally, any unusual noises, such as squealing or grinding, should prompt an immediate inspection. Neglecting brake maintenance can lead not only to diminished braking performance but also to costly damage to the rotors, calipers, and potentially other components of the braking system.

In conclusion, the 2021 Nissan Rogue's brake pads are engineered components designed to provide safe and reliable stopping power. Their composition, design, and performance characteristics are carefully optimized to meet specific requirements. Regular maintenance and timely replacement of worn brake pads are essential to ensure optimal braking performance and safety.