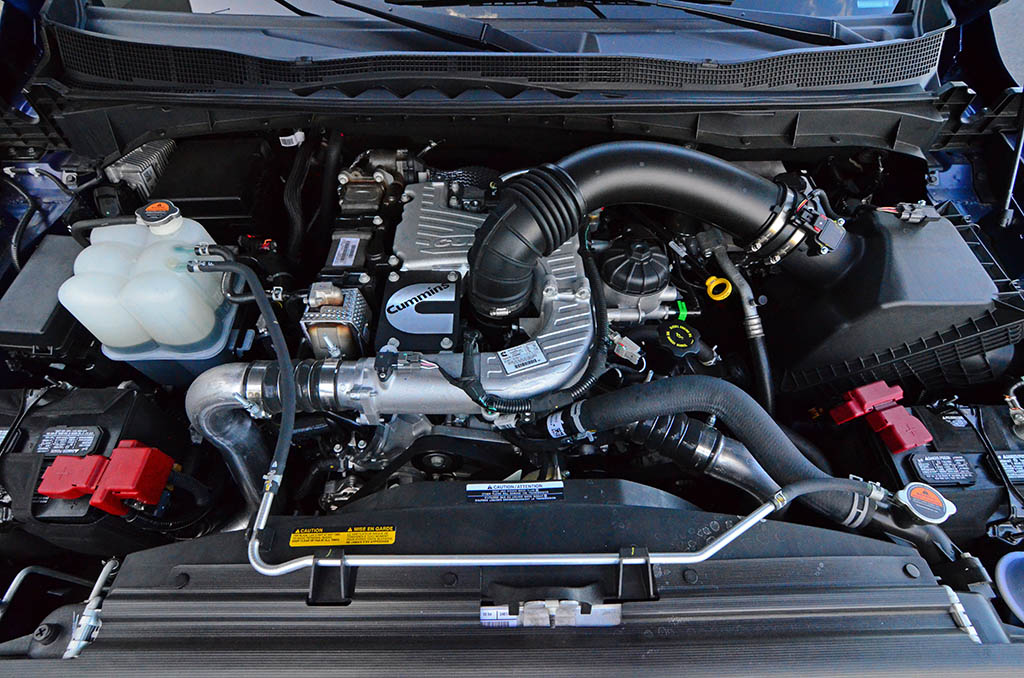

Nissan Titan Xd Diesel Engine

The Nissan Titan XD, particularly the models equipped with the Cummins 5.0L V8 Turbo Diesel engine, has always been a topic of considerable interest among truck enthusiasts. Its unique design philosophy and specific engineering choices set it apart from its competitors. This article will delve into the technical intricacies of this engine, providing an in-depth look at its key components and systems.

Engine Overview: Cummins 5.0L V8 Turbo Diesel

The heart of the Titan XD is the Cummins 5.0L V8 Turbo Diesel, a power plant designed for heavy-duty applications. Unlike some light-duty diesels that are merely adapted from gasoline engines, the 5.0L Cummins was engineered from the ground up as a dedicated diesel. This is evident in its robust construction and design features tailored for diesel combustion characteristics.

The engine displaces 5.0 liters (305 cubic inches) and features a 90-degree V8 configuration. Its bore and stroke are designed to provide a good balance of torque and horsepower, crucial for hauling and towing. The engine block is made from compacted graphite iron (CGI), a material known for its high strength and stiffness while being lighter than traditional cast iron. This contributes to the engine's overall durability and helps to reduce weight compared to a fully cast iron block.

Key Components and Systems

Let's examine some of the most important aspects of the Cummins 5.0L V8:

Cylinder Heads and Valvetrain

The engine utilizes aluminum alloy cylinder heads. Aluminum offers better thermal conductivity than cast iron, improving heat dissipation and reducing the risk of localized hot spots. Each head features four valves per cylinder (two intake and two exhaust), operated by a direct-acting overhead valve (OHV) system. The OHV configuration, while not as common in modern passenger cars, offers a compact design and robust performance suitable for the high loads and stresses of a diesel engine. The camshaft is located centrally in the engine block, and pushrods transfer motion to the rocker arms, which in turn actuate the valves. This design promotes simplicity and durability.

Fuel Injection System

A high-pressure common rail (HPCR) fuel injection system is employed. This system uses a central rail to store fuel at extremely high pressure (over 29,000 psi) and then injects it directly into the cylinders via electronically controlled injectors. The high pressure ensures excellent fuel atomization and precise metering, leading to cleaner combustion and improved fuel efficiency. Multiple injection events per combustion cycle are possible with HPCR, reducing combustion noise and emissions. The injectors themselves are solenoid-activated units, known for their reliability and responsiveness.

Turbocharging System

The Cummins 5.0L V8 stands out with its advanced turbocharging system. It employs a sequential, series-turbocharger configuration featuring two turbochargers: a smaller one and a larger one. The smaller turbocharger is designed for quick response at low engine speeds, providing excellent low-end torque and minimizing turbo lag. As engine speed increases, the larger turbocharger comes into play, delivering higher boost pressure for increased power output at higher RPMs. This arrangement provides a wider powerband than a single turbocharger system. The wastegates are electronically controlled, allowing for precise boost management and optimal performance across the engine's operating range.

The placement of the turbochargers within the valley of the V8 engine is also noteworthy. This "valley-mounted" design helps to minimize exhaust manifold volume, further improving turbocharger response.

Cooling System

The cooling system is critical for maintaining optimal engine temperatures and preventing overheating, especially under heavy load conditions. The Cummins 5.0L V8 uses a high-capacity cooling system with a large radiator and multiple cooling fans. An engine oil cooler is also integrated into the system to help dissipate heat from the engine oil, which is particularly important in a turbo diesel due to the increased thermal stress on the oil. The engine also uses a coolant filtration system to remove contaminants from the coolant, extending the life of the cooling system components.

Exhaust Aftertreatment System

Modern diesel engines require sophisticated exhaust aftertreatment systems to meet stringent emissions regulations. The Cummins 5.0L V8 incorporates a comprehensive system that includes:

- Diesel Oxidation Catalyst (DOC): Oxidizes hydrocarbons (HC) and carbon monoxide (CO) into water and carbon dioxide.

- Diesel Particulate Filter (DPF): Traps particulate matter (PM), also known as soot. The DPF undergoes periodic regeneration cycles where the trapped soot is burned off at high temperatures.

- Selective Catalytic Reduction (SCR) System: Reduces nitrogen oxides (NOx) into nitrogen and water using a diesel exhaust fluid (DEF), also known as AdBlue. DEF is injected into the exhaust stream upstream of the SCR catalyst.

The effectiveness of the aftertreatment system is monitored by various sensors, including NOx sensors and particulate matter sensors, which provide feedback to the engine control unit (ECU) to optimize emissions performance.

Engine Control Unit (ECU)

The ECU is the "brain" of the engine, responsible for controlling and managing all aspects of engine operation. It receives input from numerous sensors, including engine speed, load, temperature, and exhaust gas composition. Based on this information, the ECU adjusts fuel injection timing and duration, turbocharger boost pressure, EGR valve opening, and other parameters to optimize performance, fuel efficiency, and emissions. The ECU also monitors the health of the engine and its various systems, and it can store diagnostic trouble codes (DTCs) if any problems are detected. The ECU is programmed with sophisticated algorithms and maps to ensure optimal performance under a wide range of operating conditions.

Other Notable Features

- Forged Steel Crankshaft: For maximum strength and durability.

- Fracture-Split Connecting Rods: These rods are manufactured as one piece and then fractured, creating a perfectly matched mating surface for increased strength and precision.

- Piston Cooling Jets: Spray oil onto the underside of the pistons to help dissipate heat and reduce piston temperatures.

- Viscous Fan Clutch: The engine uses a viscous fan clutch, which engages and disengages the cooling fan based on engine temperature. This helps to improve fuel efficiency and reduce noise when cooling is not needed.

Performance and Reliability

The Cummins 5.0L V8 Turbo Diesel in the Nissan Titan XD delivers a robust combination of torque and horsepower, making it well-suited for towing and hauling. Its peak output is rated at 310 horsepower and 555 lb-ft of torque. The engine's robust design and construction contribute to its reputation for reliability. While it's not without its quirks (like any engine), it's generally considered to be a durable and dependable power plant when properly maintained. The CGI block, forged steel crankshaft, and robust valvetrain are all designed to withstand the stresses of heavy-duty use.

Conclusion

The Cummins 5.0L V8 Turbo Diesel is a sophisticated and well-engineered engine designed specifically for heavy-duty truck applications. Its combination of advanced technologies, such as the sequential turbocharging system, high-pressure common rail fuel injection, and sophisticated exhaust aftertreatment, contribute to its impressive performance and emissions characteristics. While the Titan XD didn't reach the sales volume Nissan hoped for, the engineering of the 5.0L Cummins remains a fascinating study in modern diesel technology. Understanding the intricacies of this engine provides valuable insight into the complexities of diesel engine design and its application in demanding environments. It's a testament to the engineering prowess of both Cummins and Nissan.