Nissan Versa Transmission Replacement

The Nissan Versa, known for its affordability and fuel efficiency, often sees high mileage. As with any vehicle, components wear over time, and the transmission, being a complex and critical assembly, is no exception. Replacing a Versa transmission is a significant undertaking, but understanding the process can empower DIY enthusiasts and provide valuable insight for anyone considering this repair.

Understanding the Versa Transmission

The Versa, depending on the model year, might be equipped with either a continuously variable transmission (CVT) or a traditional automatic transmission. The CVT, in particular, is a crucial element in achieving the Versa’s fuel economy. While both types perform the same fundamental function – transferring power from the engine to the wheels – their operating principles differ significantly.

CVT Operation

CVTs, unlike traditional automatics with fixed gear ratios, use a belt (usually made of steel) and two variable-diameter pulleys to provide an infinite range of gear ratios within its design limitations. One pulley is connected to the engine, and the other to the drive wheels. By varying the diameter of these pulleys, the transmission can smoothly adjust the gear ratio, keeping the engine in its optimal power band for maximum efficiency. The Versa's CVT is electronically controlled, using sensors to monitor various parameters and actuators to adjust the pulley diameters. This sophisticated system allows for seamless acceleration and efficient cruising.

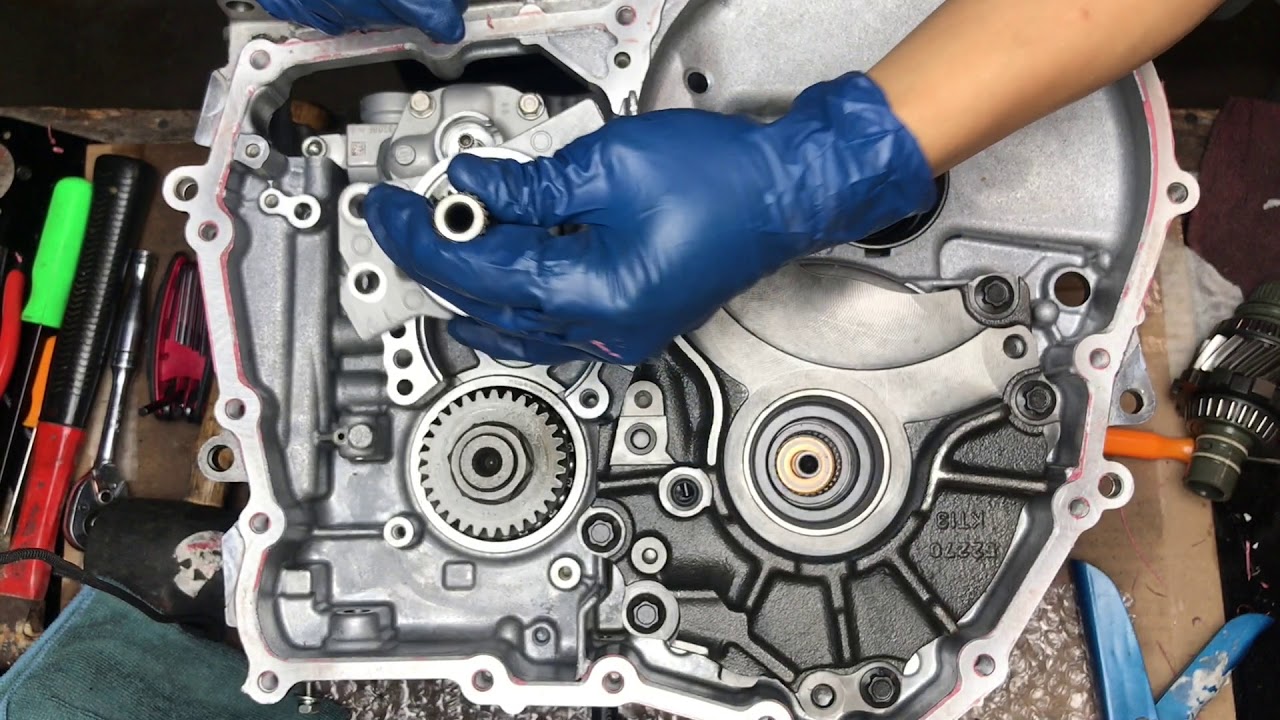

Traditional Automatic Transmission Operation

Traditional automatic transmissions utilize planetary gearsets, clutches, and bands to achieve different gear ratios. These gearsets are engaged and disengaged by hydraulic pressure controlled by a valve body, based on input from sensors and the driver's throttle input. The Versa's traditional automatic offers a set number of fixed gear ratios, providing distinct shifts as the vehicle accelerates. While not as efficient as a CVT in some situations, traditional automatics are often perceived as more durable by some drivers.

When a Transmission Replacement is Necessary

Several symptoms can indicate a failing transmission, warranting a replacement. These include:

- Slipping Gears: The engine revs up without a corresponding increase in vehicle speed.

- Rough or Erratic Shifting: Abrupt or jerky gear changes, particularly noticeable with a traditional automatic.

- Delayed Engagement: A noticeable pause between shifting into drive or reverse and the vehicle moving.

- Unusual Noises: Whining, clunking, or grinding sounds coming from the transmission area.

- Burning Smell: Often indicates overheated transmission fluid, a sign of internal damage.

- Transmission Warning Light: Illumination of the dashboard warning light (often a generic "Check Engine" light) coupled with diagnostic trouble codes (DTCs) related to the transmission.

A thorough diagnosis is crucial before committing to a replacement. Sometimes, seemingly severe transmission problems can be resolved with a fluid change, valve body repair, or sensor replacement. Scan the vehicle's computer for diagnostic codes and consult a qualified mechanic to rule out less drastic solutions.

Tools and Materials Required

Replacing a Versa transmission requires a comprehensive set of tools and materials. Safety is paramount, so invest in quality equipment and follow proper procedures.

- New or Remanufactured Transmission: Ensure it is the correct model and year for your Versa.

- New Transmission Mounts: Replace these as a matter of course, as they are likely worn.

- New Transmission Fluid: Use the correct type specified for your transmission (e.g., Nissan CVT Fluid NS-3 or equivalent).

- New Transmission Filter (if applicable): Some transmissions have a replaceable filter.

- Drain Pan: To catch fluids.

- Socket Set: Metric sockets of various sizes.

- Wrench Set: Metric wrenches of various sizes.

- Torque Wrench: Essential for tightening bolts to the correct specification.

- Pry Bars: For separating components.

- Hammer: Rubber mallet or dead-blow hammer.

- Jack and Jack Stands: To safely lift and support the vehicle.

- Wheel Chocks: To prevent the vehicle from rolling.

- Penetrating Oil: To loosen stubborn bolts.

- Shop Rags: For cleaning.

- Safety Glasses: To protect your eyes.

- Gloves: To protect your hands.

- Transmission Jack: A specialized jack designed to support and lower transmissions safely.

- Service Manual: A detailed service manual specific to your Versa model is essential.

Step-by-Step Replacement Procedure (General Outline)

This is a general outline of the transmission replacement procedure. Always consult a service manual specific to your vehicle for detailed instructions and torque specifications.

- Preparation: Disconnect the negative battery cable. Safely lift and support the vehicle on jack stands. Chock the rear wheels.

- Drain the Transmission Fluid: Locate the drain plug on the transmission pan (or CVT case) and remove it, allowing the fluid to drain completely.

- Disconnect Electrical Connectors: Carefully disconnect all electrical connectors attached to the transmission. Label each connector to ensure correct reconnection later.

- Remove the Shift Linkage: Disconnect the shift cable from the transmission shift lever.

- Disconnect Cooler Lines: Disconnect the transmission cooler lines. Plug the lines to prevent excessive fluid leakage.

- Remove the Driveshafts/Axles: Depending on the Versa's configuration (FWD), you'll need to remove the driveshafts or axles from the transmission.

- Support the Engine: Use an engine support bar or jack to support the engine's weight once the transmission is removed.

- Remove the Transmission Mounts: Remove the bolts securing the transmission mounts to the transmission and the vehicle frame.

- Position the Transmission Jack: Position the transmission jack under the transmission and secure it properly.

- Remove the Transmission Bolts: Remove the bolts that secure the transmission to the engine.

- Lower the Transmission: Carefully lower the transmission using the transmission jack. Ensure it clears all surrounding components.

- Install the New Transmission: Carefully raise the new or remanufactured transmission into position using the transmission jack. Align it with the engine and install the mounting bolts. Tighten the bolts to the specified torque.

- Reinstall Components: Reinstall all components in the reverse order of removal, including the transmission mounts, driveshafts/axles, cooler lines, shift linkage, and electrical connectors.

- Install New Transmission Fluid: Fill the transmission with the correct type and amount of fluid. Consult the service manual for the correct fill procedure.

- Reconnect the Battery: Reconnect the negative battery cable.

- Test Drive: Lower the vehicle and take it for a test drive. Check for proper shifting and any unusual noises or vibrations.

- Check Fluid Level: After the test drive, check the transmission fluid level again and add fluid as needed.

Important Considerations

- Torque Specifications: Always use a torque wrench and tighten bolts to the specified torque in the service manual. Overtightening can damage components, while undertightening can lead to leaks or failures.

- Fluid Type: Using the wrong type of transmission fluid can cause severe damage. Consult the service manual for the correct fluid specification.

- Cleanliness: Maintain a clean work environment to prevent contamination of the transmission.

- Safety: Wear safety glasses and gloves at all times. Use jack stands to support the vehicle safely.

- Professional Assistance: If you are not comfortable performing this repair, seek professional assistance from a qualified mechanic. Incorrect installation can lead to serious damage to the transmission and other vehicle components.

- CVT Specifics: CVT transmissions are particularly sensitive to proper fluid levels and calibration. Ensure the fluid level is correct and, if necessary, have the CVT recalibrated after replacement.

Conclusion

Replacing a Nissan Versa transmission is a complex but manageable task for experienced DIY mechanics. By understanding the transmission's operation, gathering the necessary tools, following the correct procedure, and adhering to safety precautions, you can successfully complete this repair. However, if you lack experience or are unsure about any aspect of the process, it is best to seek professional assistance. A faulty transmission can significantly impact the vehicle's performance and safety, making proper installation paramount.