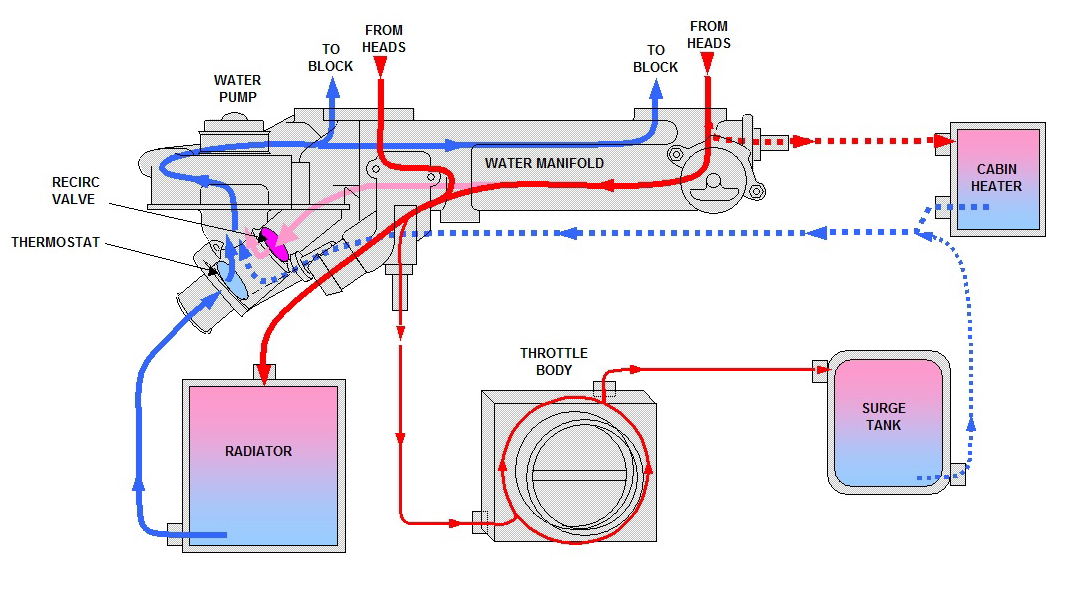

Northstar Engine Coolant Flow Diagram

The Northstar engine, a Cadillac staple for over two decades, is often remembered for its performance, but sometimes less fondly for its cooling system complexities. Understanding its coolant flow diagram is critical for maintenance, but what can its lessons teach us about the future of thermal management in increasingly electrified and complex vehicles?

Let's revisit the Northstar's coolant system briefly. Its unique design, with reverse flow cooling and a coolant passage through the engine block's valley, aimed for improved thermal efficiency and reduced cylinder head temperatures. The flow diagram illustrates a complex network of hoses, passages, a surge tank, and often, dual thermostats. While innovative for its time, it also presented challenges – susceptibility to air pockets, gasket failures, and the need for meticulous bleeding procedures after maintenance. These issues highlight the critical importance of robust design and reliable components when dealing with intricate cooling systems, a lesson highly relevant as we move towards more advanced automotive technologies.

The Rise of Electric Vehicle (EV) Thermal Management

The transition to EVs doesn't eliminate the need for thermal management; it simply shifts the focus. Instead of solely managing engine heat, EVs require precise temperature control for batteries, motors, and power electronics. Efficient thermal management is paramount for:

- Battery Life: Maintaining optimal battery temperature extends its lifespan and prevents degradation. Overheating can drastically reduce battery capacity and increase the risk of thermal runaway.

- Performance: Battery performance is highly temperature-dependent. Cooling systems prevent performance drops during high-demand driving, while heating systems ensure optimal power output in cold weather.

- Charging Speed: Fast charging generates significant heat. Effective cooling is essential for enabling faster charging rates without damaging the battery.

- Cabin Comfort: Electric vehicles often employ heat pumps to provide efficient cabin heating and cooling, further integrating the thermal management system.

Upcoming technologies in EV thermal management are moving beyond traditional liquid cooling to include more advanced solutions:

Advanced Coolants

Traditional coolants are being replaced by fluids with superior thermal properties. These include:

- Dielectric Fluids: These non-conductive fluids allow for direct cooling of battery cells and electronic components, improving heat transfer efficiency and reducing the risk of electrical shorts.

- Nanofluids: These coolants contain nanoparticles that enhance thermal conductivity, allowing for smaller and more efficient cooling systems.

- Phase Change Materials (PCMs): PCMs absorb and release heat during phase transitions (e.g., solid to liquid), providing a buffer against temperature fluctuations and improving thermal stability.

Direct Cooling Strategies

Moving away from indirect cooling (where a coolant circulates around battery modules) to direct cooling promises significant improvements. Direct cooling strategies include:

- Immersion Cooling: Submerging battery cells directly in a dielectric fluid offers exceptional heat transfer and uniform temperature distribution. This is already seeing adoption in high-performance applications and data centers.

- Microchannel Cooling: Integrating microchannels within battery cells or modules allows for highly localized and efficient heat extraction.

Integrated Thermal Management Systems

The future of EV thermal management lies in integration. Instead of separate cooling loops for different components, integrated systems combine multiple cooling functions into a single, optimized loop. This offers several advantages:

- Reduced Complexity: Fewer components, hoses, and pumps simplify the system and reduce weight.

- Improved Efficiency: Waste heat from one component can be used to heat another, maximizing energy utilization. For example, motor heat can be used to warm the cabin in cold weather.

- Enhanced Control: Advanced control algorithms can precisely manage the flow of coolant to different components, optimizing performance and efficiency based on real-time conditions.

Hybrid Systems: A Balancing Act

Hybrid vehicles present a unique thermal management challenge, requiring systems that can handle both internal combustion engine (ICE) heat and electric component cooling. This often involves:

- Dual Cooling Loops: Separate loops for the ICE and electric components, each optimized for its specific thermal requirements.

- Heat Exchangers: Devices that transfer heat between the two loops, allowing for waste heat recovery and improved overall efficiency.

- Sophisticated Control Systems: Algorithms that manage the flow of coolant between the loops, balancing the needs of the ICE and electric components based on driving conditions.

The complexity of hybrid systems demands robust and reliable components, echoing the lessons learned from the Northstar engine. Any vulnerability in the cooling system can lead to performance degradation, increased emissions, or even system failure. However, this complexity also presents opportunities for innovation, such as developing more efficient heat exchangers and more intelligent control strategies.

Smart Automotive Solutions and Thermal Management

The increasing connectivity and intelligence of modern vehicles are revolutionizing thermal management. Smart automotive solutions are enabling:

- Predictive Thermal Management: Using real-time data (e.g., weather conditions, driving patterns, navigation information) to anticipate thermal loads and proactively adjust cooling strategies. For example, pre-cooling the battery before a fast charging session or pre-heating the cabin before departure.

- Adaptive Cooling Strategies: Optimizing cooling performance based on individual driving styles and preferences.

- Remote Diagnostics and Monitoring: Monitoring coolant levels, temperatures, and pump performance remotely, enabling proactive maintenance and preventing breakdowns.

- Vehicle-to-Grid (V2G) integration: Utilizing the EV battery as a thermal storage device, enabling more efficient energy management and grid stabilization.

These smart solutions require sophisticated sensors, actuators, and control algorithms, as well as reliable data communication networks. However, they offer the potential to significantly improve the efficiency, performance, and reliability of vehicle thermal management systems.

Challenges and Opportunities

While the future of automotive thermal management is bright, several challenges must be addressed:

- Cost: Advanced cooling technologies, such as direct cooling and advanced coolants, can be expensive. Reducing costs will be crucial for widespread adoption.

- Complexity: Integrating multiple cooling functions into a single system can increase complexity and require specialized expertise. Simplification and standardization are key.

- Reliability: Ensuring the long-term reliability of advanced cooling systems is essential. Robust design, rigorous testing, and proactive maintenance are critical.

- Environmental Impact: The environmental impact of coolants and manufacturing processes must be considered. Sustainable and environmentally friendly solutions are needed.

Overcoming these challenges will require collaboration between automakers, suppliers, researchers, and policymakers. Innovation, standardization, and a focus on sustainability will be essential for unlocking the full potential of advanced automotive thermal management.

A Visionary Note

Imagine a future where vehicles seamlessly adapt to their environment, optimizing energy use and maximizing performance through intelligent thermal management. Picture self-healing cooling systems that automatically repair leaks and prevent breakdowns. Envision vehicles that share thermal energy with buildings and communities, creating a more efficient and sustainable energy ecosystem. This future is within reach, driven by innovation, collaboration, and a commitment to sustainable mobility. The lessons learned from systems like the Northstar, both in their successes and shortcomings, pave the way for the sophisticated and efficient thermal management systems of tomorrow.