P0456 Evaporative Emission System Leak Detected Very Small Leak

The P0456 diagnostic trouble code (DTC), indicating "Evaporative Emission System Leak Detected Very Small Leak," is a common headache for automotive technicians. It signifies that the vehicle's onboard diagnostic (OBD) system has detected a leak within the evaporative emission control (EVAP) system, but the leak is small enough that it doesn't immediately cause significant fuel vapor release into the atmosphere. While seemingly minor, this code shouldn't be ignored, as it can point to underlying issues affecting fuel economy, emissions compliance, and potentially even engine performance in the long run.

Understanding the EVAP System

The EVAP system is designed to prevent fuel vapors from escaping into the atmosphere. It captures these vapors, stores them temporarily (usually in a charcoal canister), and then purges them into the engine to be burned during normal operation. Modern EVAP systems are complex, incorporating numerous components:

- Fuel Tank: The source of the fuel vapors. Engineering choices here include materials resistant to fuel degradation and pressure variations.

- Fuel Cap: A seemingly simple component, but a common culprit for P0456. It must seal tightly to prevent vapor leaks.

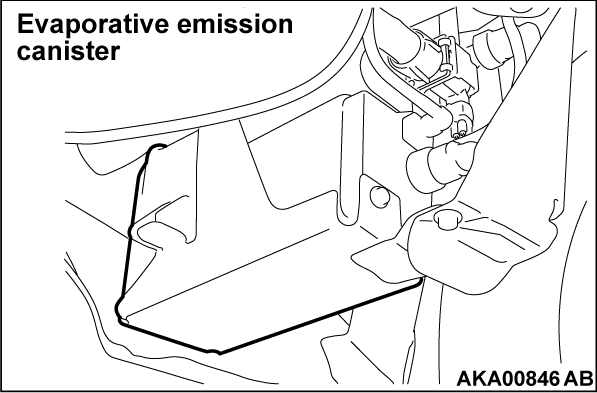

- Charcoal Canister: Contains activated charcoal that absorbs and stores fuel vapors. Canister design dictates capacity and efficiency.

- Purge Valve: Controls the flow of vapor from the canister to the engine intake manifold. Typically a solenoid valve controlled by the PCM.

- Vent Valve: Allows fresh air to enter the EVAP system. Often located near the charcoal canister. Also a solenoid valve controlled by the PCM.

- Pressure Sensor: Monitors pressure or vacuum within the EVAP system. Provides feedback to the PCM for leak detection.

- Hoses and Tubing: Connect all the components, carrying fuel vapors. Material selection is crucial to withstand fuel exposure and temperature changes.

Technical Specifications and Engineering Considerations

The P0456 code is triggered when the PCM detects a pressure difference in the EVAP system that exceeds a pre-defined threshold, indicating a leak. The "very small leak" designation typically refers to a leak rate in the range of 0.020 to 0.040 inches in diameter. This size leak is difficult to detect without specialized equipment. The PCM uses sophisticated algorithms to monitor pressure decay over time, compensating for temperature changes and other factors that can influence EVAP system pressure. These algorithms vary depending on the vehicle manufacturer and model year.

Engineering choices in EVAP system design directly impact the likelihood of P0456 occurring. For example:

- Hose Materials: Using higher-quality, fuel-resistant rubber or plastic hoses can reduce the risk of cracking and leaks over time. Alternatives include using Teflon-lined hoses for improved permeation resistance, but these are typically more expensive.

- Valve Design: Robust valve designs with durable seals are essential for preventing leaks. Solenoid valve reliability is a critical factor.

- Canister Placement: Positioning the charcoal canister in a location that minimizes exposure to heat and road debris can extend its lifespan and prevent damage that could lead to leaks.

- Diagnostic Algorithms: More sophisticated leak detection algorithms can improve the accuracy and sensitivity of the EVAP system diagnostics, reducing the chances of false positives or undetected leaks.

Real-World Performance and Diagnostic Procedures

Diagnosing a P0456 code requires a systematic approach. Common diagnostic tools include:

- Scan Tool: To read the DTC and access EVAP system data (pressure readings, valve status, etc.).

- Smoke Machine: The most effective tool for locating small leaks. Introduces a visible smoke into the EVAP system, allowing technicians to pinpoint the source of the leak.

- EVAP Tester: A specialized tool that can pressurize or apply vacuum to the EVAP system to test for leaks. May include flow meters for quantifying leak rates.

- Multimeter: To check the electrical circuits of the purge and vent valves.

The diagnostic procedure typically involves:

- Visual Inspection: Thoroughly inspect all EVAP system components, including the fuel cap, hoses, valves, and canister, for signs of damage, cracks, or loose connections. This is often overlooked, but can save a lot of time.

- Fuel Cap Test: Test the fuel cap's sealing ability using a specialized fuel cap tester. A faulty fuel cap is a common cause of P0456.

- Smoke Test: Introduce smoke into the EVAP system and carefully inspect all components for escaping smoke.

- Valve Testing: Verify that the purge and vent valves are functioning correctly. Use a scan tool to activate the valves and listen for proper operation. Check the valve's electrical circuits with a multimeter.

- Component Isolation: If a leak is suspected but difficult to pinpoint, isolate sections of the EVAP system to narrow down the location of the leak.

Common Causes of P0456:

- Loose or Damaged Fuel Cap

- Cracked or Deteriorated Hoses

- Faulty Purge or Vent Valve

- Damaged Charcoal Canister

- Leaking Fuel Tank or Fuel Filler Neck

- Corroded or Damaged EVAP System Lines

Comparison with Alternatives

Alternative EVAP system designs exist, although the fundamental principles remain the same. Some manufacturers use different types of pressure sensors or valve designs. The primary difference lies in the specific algorithms used for leak detection and the sensitivity of the system.

Pros of Current EVAP Systems:

- Effective at preventing fuel vapor emissions.

- Relatively reliable, with a long service life for most components.

- Diagnostic tools and procedures are well-established.

Cons of Current EVAP Systems:

- Can be complex and difficult to diagnose, especially small leaks.

- Hoses and valves are prone to degradation over time.

- False positives can occur due to temperature changes or sensor inaccuracies.

Reliability Aspects and Maintenance Tips

The reliability of the EVAP system depends on several factors, including the quality of the components, the operating environment, and the maintenance practices. Regular maintenance can help prevent P0456 codes and extend the lifespan of the EVAP system.

Maintenance Tips:

- Inspect the Fuel Cap Regularly: Check the fuel cap for cracks, damage, or a worn seal. Replace it if necessary.

- Inspect Hoses: Periodically inspect the EVAP system hoses for cracks, leaks, or deterioration. Replace damaged hoses promptly.

- Avoid Overfilling the Fuel Tank: Overfilling can saturate the charcoal canister and reduce its effectiveness.

- Use Quality Fuel: Poor quality fuel can contain contaminants that can damage EVAP system components.

- Address EVAP Codes Promptly: Ignoring EVAP codes can lead to more serious problems.

Future Trends

Future trends in EVAP system technology are likely to focus on improved efficiency, reliability, and diagnostics. Some potential developments include:

- More Durable Materials: The use of more durable materials, such as Teflon-lined hoses and advanced polymers, can extend the lifespan of EVAP system components and reduce the risk of leaks.

- Improved Leak Detection Algorithms: More sophisticated leak detection algorithms can improve the accuracy and sensitivity of the EVAP system diagnostics, reducing the chances of false positives or undetected leaks.

- Self-Sealing Technology: The development of self-sealing technology for hoses and connections could prevent leaks from developing in the first place.

- Integration with Electric Vehicles: As electric vehicles (EVs) become more prevalent, EVAP systems will need to be adapted to address the unique challenges of fuel vapor management in hybrid and plug-in hybrid vehicles. This will likely involve more sophisticated vapor recovery and storage systems.

- Remote Diagnostics: Future vehicles may be equipped with remote diagnostics capabilities that allow technicians to monitor EVAP system performance and identify potential problems before they become serious.

Conclusion

The P0456 code represents a small but potentially significant issue with the vehicle's EVAP system. Understanding the system's design, function, and diagnostic procedures is essential for automotive professionals. By following a systematic approach to diagnosis and repair, technicians can effectively address P0456 codes and ensure that vehicles meet emissions standards. Looking ahead, the automotive industry is constantly evolving, and advancements in EVAP system technology will continue to improve the efficiency, reliability, and environmental performance of vehicles. The increasing complexity of automotive systems necessitates continuous learning and adaptation for automotive professionals to remain proficient in their field. The future demands a strong understanding of both mechanical and electronic systems, coupled with a commitment to staying abreast of the latest technological advancements.