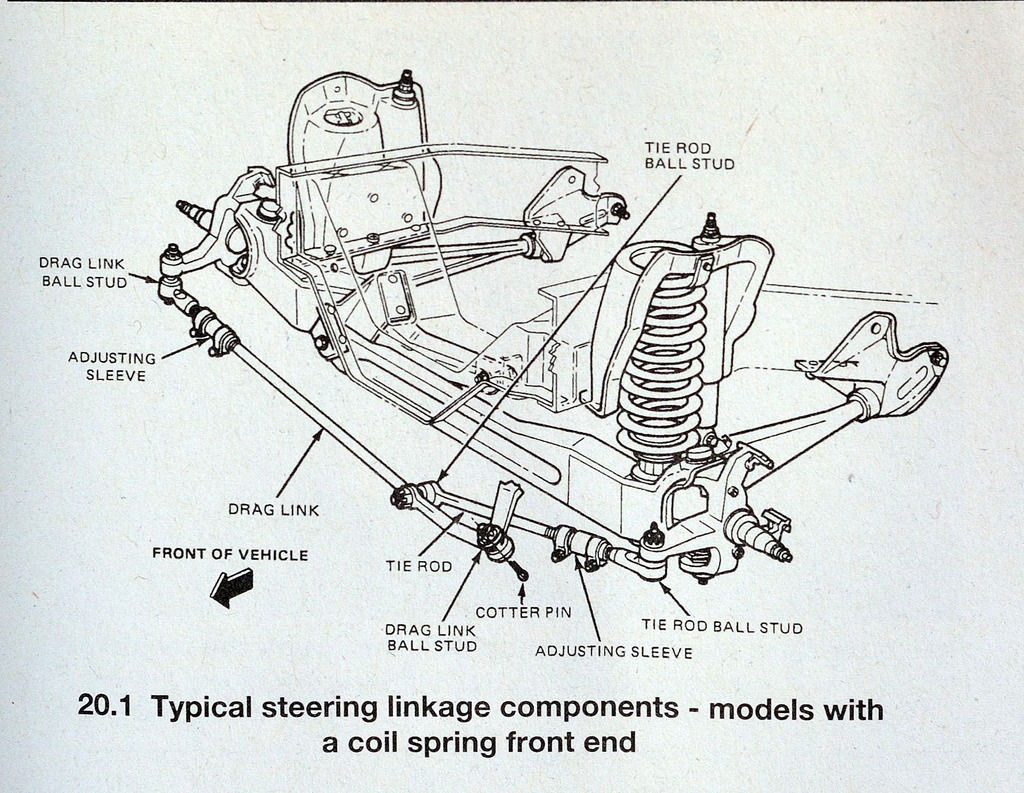

Pitman Arm Idler Arm Diagram

For the seasoned car enthusiast, the undercarriage is more than just a collection of greasy bits; it's a symphony of engineering that dictates how a vehicle handles, feels, and ultimately, connects with the road. And at the heart of older, particularly rear-wheel-drive systems, lies a critical steering linkage – the Pitman arm and idler arm. These often-overlooked components play a vital role in translating steering wheel input into directional changes. While their function seems simple enough, the nuances in design, application, and maintenance can significantly impact your driving experience. Let's dive deep into the world of Pitman and idler arms, comparing different models, engines, and technologies to help you understand the subtle differences and keep your classic ride steering true.

The Dynamic Duo: Pitman Arm & Idler Arm Explained

Before we get into the specifics, let's quickly recap what these parts do. The Pitman arm connects to the steering box (or rack in some systems) and converts the rotary motion from the steering box into linear motion. This linear motion is then transferred to the center link or relay rod. The Idler arm, mounted on the opposite side of the vehicle from the Pitman arm, supports the center link or relay rod and mirrors the Pitman arm's movement, ensuring the steering geometry remains consistent throughout the steering range. Think of them as a pair of synchronized dancers ensuring the car moves smoothly and predictably.

Variations Across Models and Engines

The specific designs and specifications of Pitman and idler arms vary considerably across different makes, models, and even engine configurations. This is due to several factors, including vehicle weight, steering geometry requirements, and the intended use of the vehicle. For example:

- Heavy-Duty Trucks vs. Passenger Cars: Trucks and SUVs, especially those designed for towing or off-road use, typically employ much beefier Pitman and idler arms compared to smaller passenger cars. This is necessary to handle the increased weight and stress placed on the steering system.

- Engine Size and Placement: Sometimes, seemingly unrelated components like engine size and placement can influence the design. A larger, heavier engine might require a more robust steering system overall, leading to slightly different arm specifications.

- Steering Gear Ratios: Vehicles with different steering gear ratios may require altered arm lengths to achieve the desired steering feel and responsiveness. A quicker steering ratio might benefit from a slightly shorter Pitman arm for increased responsiveness.

Here's a simplified spec table illustrating some potential differences (Note: these are illustrative and specific values will vary depending on the actual vehicle):

| Vehicle Model | Pitman Arm Length (Approx.) | Idler Arm Mounting Style | Common Failure Point |

|---|---|---|---|

| 1969 Chevrolet Camaro | 6.25 inches | Bolt-on bracket | Ball joint wear |

| 1978 Ford F-150 | 7.5 inches | Bolt-on frame | Bushing wear |

| 1995 Jeep Cherokee | 6.0 inches | Bolt-on frame | Ball joint and bushing wear |

Pros and Cons: The Good, The Bad, and The Wobbly

Understanding the advantages and disadvantages of a well-functioning vs. a worn-out system is crucial.

Pros of a Healthy Pitman/Idler Arm System:

- Precise Steering: A tight and responsive steering feel, allowing for confident handling.

- Improved Vehicle Stability: Reduces wandering and improves stability, especially at higher speeds.

- Reduced Tire Wear: Proper steering geometry minimizes uneven tire wear.

- Enhanced Safety: Predictable steering response is essential for safe driving.

Cons of a Worn Pitman/Idler Arm System:

- Vague Steering: A noticeable lack of precision and responsiveness.

- Wandering and Instability: The vehicle may drift or wander, requiring constant steering corrections.

- Increased Tire Wear: Premature and uneven tire wear due to misalignment.

- Potential Safety Hazard: Compromised steering control can be dangerous, especially in emergency situations.

- Knocking or Clunking Noises: Audible signs of worn-out joints or bushings.

Real-World Driving Impressions: Feeling the Difference

The impact of a properly maintained (or neglected) Pitman and idler arm system is most evident in the driving experience. Imagine piloting a classic muscle car with a brand-new, perfectly aligned steering system. The steering is crisp and direct, responding instantly to your inputs. You feel a strong connection to the road, allowing you to confidently navigate corners and enjoy the raw power of the engine. Now picture the same car, but with worn-out ball joints and sloppy bushings in the steering linkage. The steering feels vague and unresponsive, requiring constant corrections to keep the car tracking straight. Every bump and imperfection in the road is amplified, making the driving experience tiring and frustrating. The difference is night and day.

"I remember replacing the entire steering linkage on my '67 Mustang," recalls seasoned mechanic and classic car enthusiast, Mark Johnson. "Before the replacement, it felt like I was wrestling a greased pig. Afterwards, it was like driving a brand new car. The difference was incredible."

The same holds true for trucks and SUVs. A worn steering system on a truck can make towing a trailer a white-knuckle experience, while a tight and well-maintained system inspires confidence and control.

Modern Advancements and Alternatives

While the traditional Pitman arm and idler arm system is still found on many older vehicles, modern cars have largely transitioned to rack-and-pinion steering systems. Rack-and-pinion systems offer several advantages, including:

- Improved Steering Precision: More direct and responsive steering feel.

- Reduced Weight: Typically lighter than traditional systems.

- Fewer Moving Parts: Generally simpler and more reliable.

However, some enthusiasts argue that rack-and-pinion systems lack the classic feel and feedback of older steering systems. Furthermore, upgrading a classic car to rack-and-pinion steering can be a complex and expensive undertaking.

Maintenance and Troubleshooting

Regular inspection and maintenance are essential for keeping your Pitman and idler arm system in top condition. Key areas to check include:

- Ball Joints: Inspect for play or looseness.

- Bushings: Look for cracks, wear, or excessive play.

- Mounting Points: Ensure all bolts and fasteners are properly tightened.

- Grease Fittings: Regularly lubricate all grease fittings with the appropriate grease.

Common symptoms of a failing Pitman or idler arm include:

- Excessive play in the steering wheel.

- Wandering or drifting at highway speeds.

- Uneven tire wear.

- Knocking or clunking noises from the front end.

Addressing these issues promptly can prevent further damage and ensure your vehicle remains safe and enjoyable to drive.

The Verdict: A Vital Link to Driving Pleasure

The Pitman arm and idler arm might seem like simple components, but they play a critical role in the overall driving experience. Understanding their function, variations, and potential issues is essential for any car enthusiast who wants to maintain a classic ride or simply appreciate the engineering that goes into a well-handling vehicle. Whether you're restoring a vintage muscle car or keeping your truck in top condition, paying attention to these often-overlooked parts can make a world of difference.

So, here's a fun question to ignite the debate: Do you think the "feel" of a well-maintained Pitman/Idler arm steering system is superior to modern rack-and-pinion, even if the latter offers objectively better performance? Let the arguments begin!