Port Fuel Injection Vs Direct Injection

Alright, let's dive into the nitty-gritty of engine fuel delivery – specifically, the age-old debate of Port Fuel Injection (PFI) versus Direct Injection (DI). Both systems do the same basic job: getting fuel into the engine to be burned. But *how* they do it makes a huge difference in performance, efficiency, and even maintenance. Think of it like delivering a package: one method drops it at your doorstep, the other delivers it right into your hand. Both get it to you, but the process is distinct.

Port Fuel Injection (PFI)

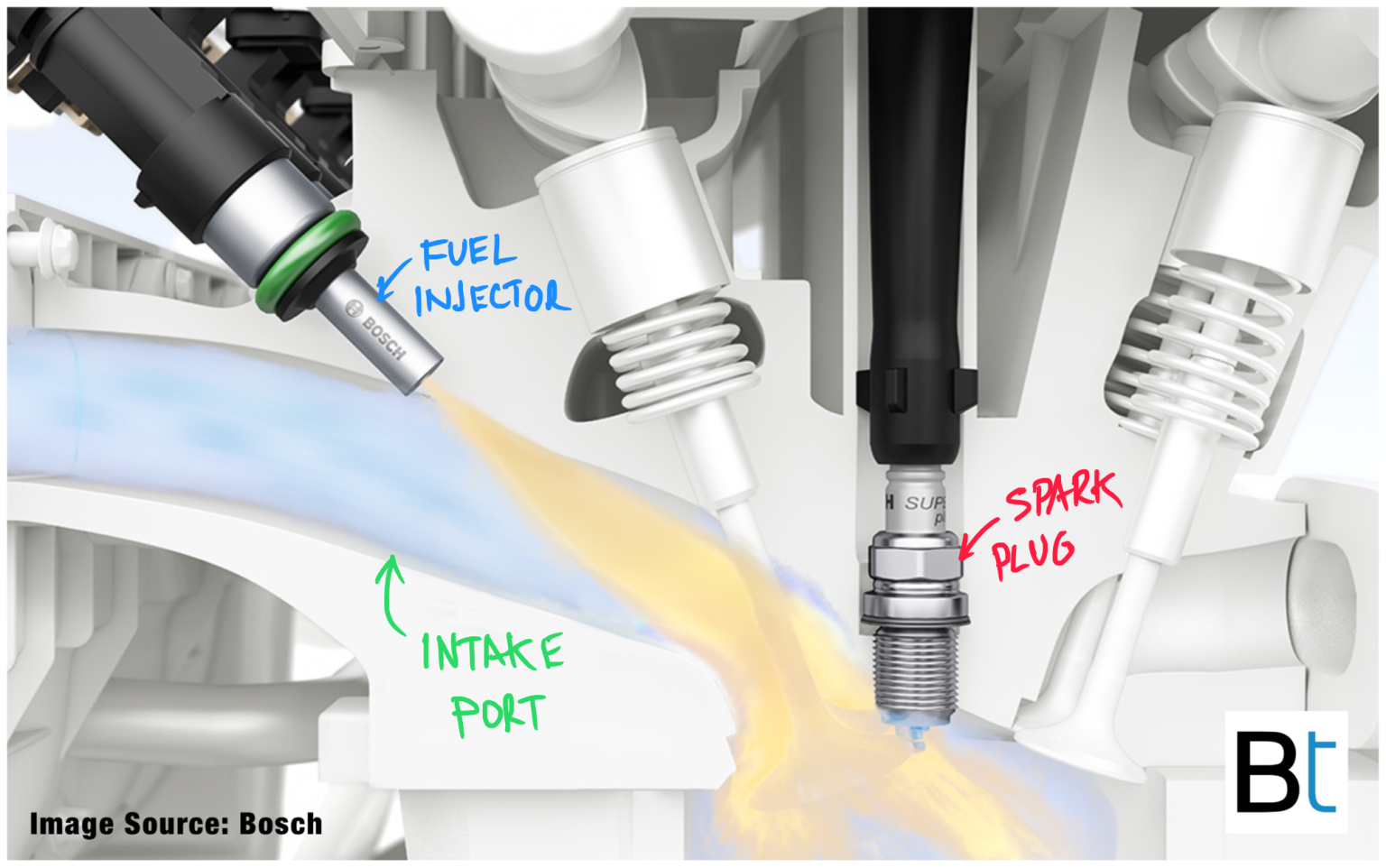

PFI, also sometimes referred to as Multiport Fuel Injection (MPFI), is the older and, in many ways, simpler of the two technologies. In a PFI system, fuel injectors are located in the intake manifold, upstream of the intake valves. Each cylinder has its own injector, hence the "multiport" designation.

How it Works

Here's the sequence of events in a typical PFI system:

- The Engine Control Unit (ECU) determines how much fuel is needed based on various sensor inputs (throttle position, mass airflow, engine speed, etc.).

- The ECU signals the appropriate injector to open for a specific duration (the pulse width).

- The injector sprays fuel into the intake port. This fuel mixes with incoming air.

- The intake valve opens, and the air-fuel mixture is drawn into the cylinder during the intake stroke.

- The mixture is compressed, ignited by the spark plug, and the combustion process pushes the piston to generate power.

A key aspect of PFI is that the fuel has time to mix with air before entering the cylinder. This leads to more homogenous air-fuel mixture than some direct injection systems.

Advantages of PFI

- Simplicity and Cost: PFI systems are generally simpler in design and therefore cheaper to manufacture and maintain. Injectors operate at relatively low pressures (around 40-60 PSI), reducing the demands on the fuel pump and associated components.

- Intake Valve Cleaning: One of the biggest benefits of PFI is its inherent ability to clean the intake valves. The fuel, sprayed onto the back of the intake valve, acts as a solvent, washing away carbon deposits that can accumulate over time. This helps to maintain optimal airflow and prevent performance degradation.

- Reduced Particulate Emissions: PFI tends to produce lower particulate emissions compared to early direct injection systems, although modern DI has largely caught up in this area with sophisticated injection strategies.

- Easier to Diagnose and Repair: Due to the simpler design, PFI systems are generally easier for mechanics to diagnose and repair. Parts are readily available and usually less expensive than their DI counterparts.

Disadvantages of PFI

- Lower Fuel Efficiency: Because the fuel is injected into the intake port and has to travel some distance before reaching the cylinder, some fuel can condense on the port walls, leading to less efficient combustion. This generally results in lower fuel economy compared to direct injection.

- Lower Power Potential: PFI systems can be limited in their ability to provide precise fuel control, particularly at higher engine speeds and loads. This can restrict power output compared to DI.

- Knock Sensitivity: Due to the intake charge being heated in the intake manifold, PFI engines are more susceptible to pre-ignition or knock under high load.

Direct Injection (DI)

Direct Injection (DI), also known as Gasoline Direct Injection (GDI), represents a more advanced approach to fuel delivery. As the name suggests, the fuel injector is located directly inside the cylinder, injecting fuel directly into the combustion chamber. This is a significant departure from PFI.

How it Works

The process unfolds as follows:

- The ECU monitors engine parameters and calculates the required fuel quantity.

- The ECU commands the injector to spray fuel directly into the cylinder. This happens either during the intake stroke (homogeneous charge) or the compression stroke (stratified charge - more on this later).

- Air enters the cylinder through the intake valve, creating a mixture with the injected fuel.

- The mixture is compressed and then ignited by the spark plug, leading to combustion and power generation.

DI systems operate at much higher fuel pressures than PFI, typically ranging from 2,000 to 3,000 PSI or even higher in some modern applications. This high pressure is necessary to atomize the fuel effectively within the cylinder.

Advantages of DI

- Improved Fuel Efficiency: Injecting fuel directly into the cylinder allows for more precise control over the air-fuel mixture. This reduces fuel wasted on port walls and creates more efficient combustion, resulting in better fuel economy.

- Increased Power Output: DI enables higher compression ratios and more aggressive spark timing, leading to increased power and torque. The precise fuel control also allows for optimized combustion at high engine speeds.

- Reduced Knock: The direct injection of fuel into the cylinder cools the air charge, reducing the likelihood of engine knock.

- Stratified Charge Capability: Some DI systems can operate in a "stratified charge" mode, particularly at light loads. In this mode, a rich air-fuel mixture is concentrated around the spark plug, while the rest of the cylinder contains a very lean mixture. This allows for ultra-lean burn and exceptional fuel economy.

Disadvantages of DI

- Carbon Buildup on Intake Valves: This is the biggest drawback of DI. Because fuel is no longer washing over the intake valves, carbon deposits can accumulate, restricting airflow and reducing engine performance. This requires periodic cleaning (usually manual cleaning or walnut blasting) which adds to the cost of ownership.

- Higher Cost and Complexity: DI systems are more complex and expensive to manufacture and maintain than PFI systems. High-pressure fuel pumps and injectors are costly, and their precision requires tighter tolerances and more sophisticated controls.

- Potential for Increased Particulate Emissions: Although modern DI systems have mitigated this with improvements in injector design and combustion strategies, early DI engines were known to produce higher levels of particulate matter (soot) than PFI engines. This can require the use of gasoline particulate filters (GPFs) in some regions.

- More Difficult to Diagnose and Repair: The high-pressure components and sophisticated controls make DI systems more challenging to diagnose and repair. Specialized tools and knowledge are often required.

- Noisier Operation: High-pressure fuel injection can be more audible, leading to a characteristic "ticking" sound from the engine.

The Hybrid Approach: GDI with PFI

To get the best of both worlds, some manufacturers are now employing a hybrid approach: a combination of GDI and PFI. These systems use both direct injectors and port injectors. The ECU can switch between the two, or use both simultaneously, depending on the operating conditions. This allows for high performance and fuel efficiency, while also mitigating the carbon buildup issue on the intake valves.

Which is Right for You?

The "best" fuel injection system depends on your priorities. If you're looking for maximum fuel economy and performance, and don't mind the potential maintenance costs associated with carbon buildup, DI is likely the better choice. If you prioritize simplicity, affordability, and ease of maintenance, PFI is a solid option. And if you want the best of both worlds, look for a vehicle with a GDI/PFI hybrid system.

Ultimately, understanding the strengths and weaknesses of each system will help you make an informed decision about your next vehicle or even inform your modifications to an existing one. Remember, knowledge is power – especially when it comes to engines!