Power Steering Pump Bolt Size

Power steering is one of those features we take for granted until it's gone. But when that groaning starts, or the wheel becomes a workout, chances are your power steering pump is complaining. And often, the culprit can be something as seemingly minor as a power steering pump bolt. This article dives into the often-overlooked world of power steering pump bolts, focusing on their size, why they matter, troubleshooting issues related to them, and how to keep your system healthy.

Understanding Power Steering Pump Bolts: More Than Just Fasteners

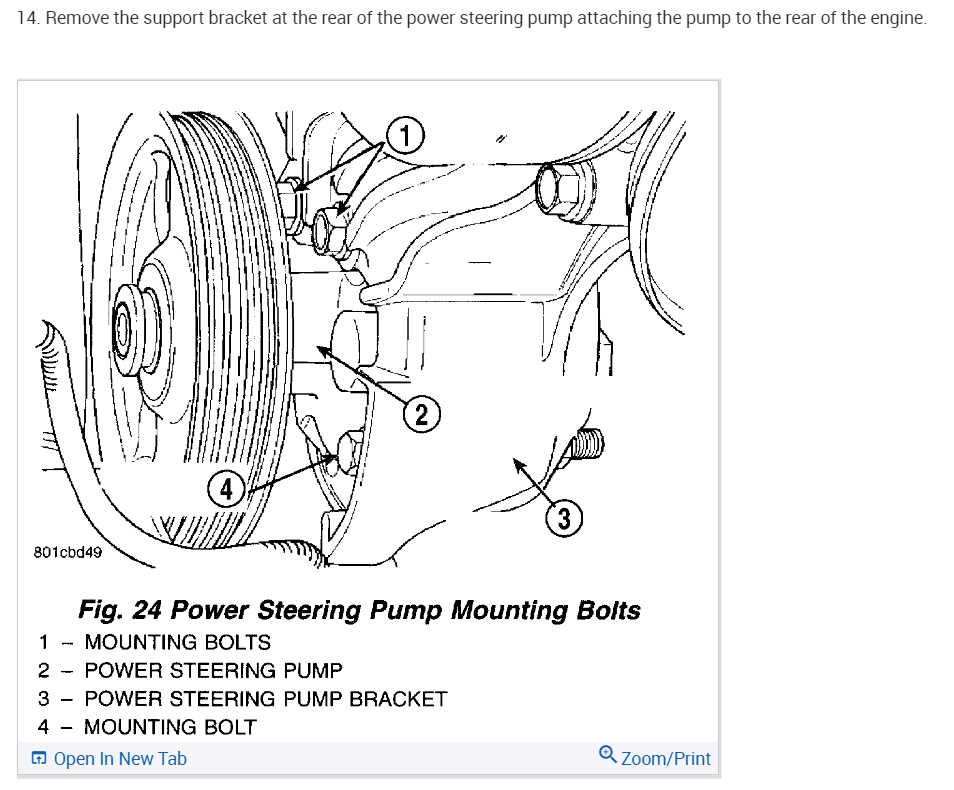

Power steering pump bolts secure the pump to its bracket on the engine. They may seem like simple fasteners, but they play a critical role in maintaining proper pump alignment and preventing vibration. Incorrect size, damaged threads, or loose bolts can lead to a cascade of problems.

The Importance of Correct Size: Using the wrong bolt size is a recipe for disaster. A bolt that's too short won't fully engage the threads, leading to a weak connection that can easily strip or vibrate loose. A bolt that's too long can bottom out before properly clamping the pump, or even damage other components behind the bracket. A wrong diameter can mean it won't thread in properly, or will weaken the bolt and the threads in the engine block or mounting bracket.

Bolt Material Matters: Often overlooked, the grade of the bolt is just as important as its size. Power steering pumps, especially on high-performance or heavy-duty vehicles, can generate significant vibrations. Using a low-grade bolt can lead to fatigue failure and breakage.

Common Symptoms of Power Steering Pump Bolt Issues

Here are some telltale signs that your power steering pump bolts might be causing problems:

- Power Steering Noise (Whining or Groaning): This is a classic symptom. Loose bolts allow the pump to vibrate, amplifying its normal operating sounds.

- Power Steering Fluid Leaks: Vibration caused by loose bolts can stress the pump's seals and connections, leading to leaks.

- Loss of Power Steering Assist: If the pump isn't securely mounted, it might not be able to generate the necessary pressure, resulting in reduced or intermittent power steering assist.

- Visible Pump Movement or Vibration: In severe cases, you might be able to see the pump vibrating excessively while the engine is running.

- Stripped Bolt Threads: If you've recently worked on the power steering pump and are having trouble tightening the bolts, the threads might be stripped in the pump housing, mounting bracket or even the engine block.

Troubleshooting Power Steering Pump Bolt Problems

Problem 1: Power Steering Pump Noise and Vibration

Symptom: Loud whining or groaning noise from the power steering pump, especially at low speeds. Excessive vibration felt through the steering wheel.

Possible Causes:

- Loose Power Steering Pump Bolts: This is the most common cause.

- Incorrect Bolt Torque: Even if the bolts are present, they might not be tightened to the correct torque specification.

- Damaged Bolt Threads: Stripped or cross-threaded bolts won't hold properly.

- Worn or Damaged Mounting Bracket: A cracked or weakened bracket can contribute to vibration.

Solution:

- Inspect the Bolts: Visually check the bolts for looseness, damage, or corrosion. Ensure they are the correct type.

- Tighten to Specification: Consult your vehicle's repair manual for the correct torque specification. Use a torque wrench to tighten the bolts to the recommended value. Overtightening can strip the threads, so be careful.

- Thread Repair: If the threads are stripped, you might be able to repair them using a thread repair kit (e.g., Heli-Coil). If the damage is too severe, you may need to replace the pump housing or mounting bracket.

- Bracket Inspection: Carefully inspect the mounting bracket for cracks or damage. Replace it if necessary.

Example: On a 2010 Honda Civic, a common issue is a whining power steering pump. Often, simply tightening the three 10mm bolts that hold the pump in place to the specified torque (usually around 16 lb-ft) will resolve the noise. However, if the noise persists, further investigation into the pump itself is needed.

Problem 2: Power Steering Fluid Leak Around the Pump

Symptom: Visible power steering fluid leak around the pump area. Fluid level in the reservoir drops noticeably.

Possible Causes:

- Loose Power Steering Pump Bolts: Vibration can damage seals and connections, causing leaks.

- Damaged Pump Seals: The pump's internal seals might be worn or damaged.

- Loose Hose Connections: The hoses connecting to the pump might be loose or cracked.

Solution:

- Identify the Source of the Leak: Clean the area around the pump and hoses. Then, run the engine and observe where the leak is originating.

- Tighten Connections: If the leak is coming from a hose connection, tighten the clamp or fitting. Replace the hose if it's cracked or damaged.

- Inspect and Tighten Bolts: Check the power steering pump bolts for looseness. Tighten them to the correct torque specification.

- Seal Replacement: If the leak is coming from the pump itself, you might need to replace the pump's seals or the entire pump.

Example: On a 2015 Ford F-150, a common leak point is the high-pressure hose connection to the power steering pump. Before replacing the pump, always check the hose connection and ensure the bolts holding the pump are tight. The bolts are usually 13mm and should be tightened to around 30 lb-ft.

Problem 3: Loss of Power Steering Assist

Symptom: Steering becomes difficult, especially at low speeds. Steering wheel feels heavy and unresponsive.

Possible Causes:

- Loose Power Steering Pump Bolts: The pump isn't operating efficiently due to improper mounting.

- Low Power Steering Fluid Level: Insufficient fluid reduces the pump's ability to generate pressure.

- Faulty Power Steering Pump: The pump might be failing internally.

- Clogged Power Steering System: A blockage in the system can restrict fluid flow.

Solution:

- Check Fluid Level: Ensure the power steering fluid reservoir is filled to the correct level.

- Inspect and Tighten Bolts: Check the power steering pump bolts for looseness. Tighten them to the correct torque specification.

- Bleed the System: Air in the power steering system can cause a loss of assist. Follow the manufacturer's instructions for bleeding the system.

- Pump Diagnosis: If the fluid level is correct and the bolts are tight, the pump might be faulty. Have the pump tested by a qualified mechanic.

Example: In older vehicles like a 1998 Jeep Cherokee, a complete loss of power steering assist can sometimes be traced back to loose power steering pump bolts combined with a worn-out pump. Replacing the pump *and* ensuring the correct bolt size and torque are used during installation is crucial for a lasting repair. These bolts are typically 10mm or 13mm, depending on the engine.

Real-World Example: The Case of the Mysterious Noise

A customer brought in their 2012 Toyota Camry complaining of a loud whining noise from the engine compartment. The noise was most pronounced when turning the steering wheel. The mechanic initially suspected the power steering pump itself. However, upon closer inspection, they noticed that one of the power steering pump bolts was missing entirely. The remaining two bolts were loose. Replacing the missing bolt and tightening the remaining ones to the correct torque (21 Nm) completely eliminated the noise. This simple fix saved the customer the cost of a new power steering pump.

Preventative Maintenance for Power Steering Systems

Taking a proactive approach can prevent many power steering problems. Here's how to keep your system in top shape:

- Regularly Check Fluid Level: Check the power steering fluid level at least every oil change. Low fluid levels can damage the pump.

- Use the Correct Fluid: Always use the power steering fluid specified in your vehicle's owner's manual. Using the wrong fluid can damage the pump and seals.

- Inspect Hoses and Connections: Regularly inspect the power steering hoses and connections for leaks or damage. Replace any cracked or worn hoses.

- Check for Leaks: Periodically check for leaks around the power steering pump and rack. Address any leaks promptly to prevent further damage.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the power steering system. Whining, groaning, or squealing noises can indicate a problem.

- Torque Check: Every year or so, especially after any work on the power steering system, it's a good idea to check the torque on the pump mounting bolts.

Conclusion

Power steering pump bolts might seem insignificant, but they play a vital role in the proper functioning of your power steering system. Understanding their importance, recognizing the symptoms of bolt-related problems, and performing regular maintenance can save you time, money, and headaches. By taking care of these small details, you can keep your car running smoothly and enjoy effortless steering for years to come. Always consult your vehicle's repair manual for specific bolt sizes and torque specifications. If in doubt, seek the help of a qualified mechanic.