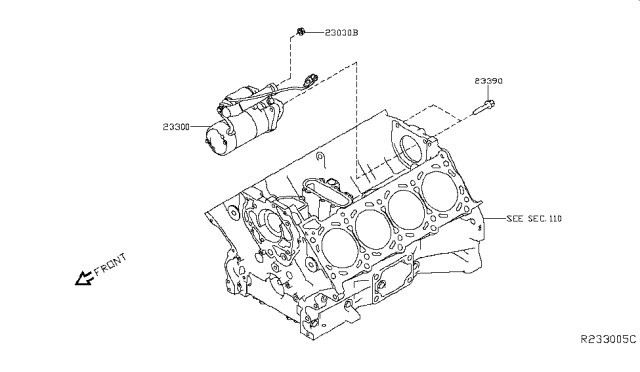

Starter For 2017 Nissan Titan

The 2017 Nissan Titan, a robust contender in the full-size truck market, relies on a sophisticated, yet relatively simple, starting system to bring its powerful engine to life. This article will dissect the starter motor used in the 2017 Titan, focusing on its components, operation, and common failure points. We'll delve into the electromechanical workings, providing a technical overview suitable for the curious reader and aspiring automotive engineer.

The Starter System: An Overview

The starting system's primary function is to crank the engine – to rotate the crankshaft – until the combustion process can sustain itself. In essence, it replaces the hand-cranking method of early automobiles with an electric motor powered by the vehicle's battery. The 2017 Titan's starting system consists of several key components working in concert:

- Battery: The energy source, typically a 12-volt lead-acid battery, providing the initial electrical power.

- Ignition Switch: A control switch that, when turned to the "start" position, initiates the starting sequence.

- Starter Relay: A high-current switch activated by the ignition switch, sending power to the starter solenoid. This is often implemented as a safety measure to prevent excessive current draw through the ignition switch itself.

- Starter Solenoid: An electromagnetic switch that performs two crucial functions: engaging the starter motor and connecting the battery's full power to the motor.

- Starter Motor: The electromechanical device that converts electrical energy into mechanical rotation, turning the engine's crankshaft.

- Flywheel/Flexplate: A toothed wheel attached to the engine's crankshaft, providing a surface for the starter motor's pinion gear to engage.

The Starter Motor: A Detailed Look

The heart of the starting system is the starter motor itself. Let's break down its construction and operation:

Components:

- Housing: A robust metal case that encloses and protects the internal components.

- Field Windings/Permanent Magnets: Creates a strong magnetic field within the motor. Older designs typically use field windings – coils of wire carrying current to generate the magnetic field. Newer designs often utilize permanent magnets, offering improved efficiency and reduced size. The 2017 Titan likely employs a permanent magnet design for its starter.

- Armature: A rotating assembly consisting of a shaft, laminated iron core, and multiple windings of copper wire. The armature interacts with the magnetic field, generating torque.

- Commutator: A segmented copper ring attached to the armature. Brushes make contact with the commutator, providing a path for electrical current to flow into the armature windings.

- Brushes: Typically made of carbon, the brushes press against the commutator, transferring electrical current to the rotating armature.

- Pinion Gear: A small gear attached to the starter motor's output shaft. This gear engages with the flywheel or flexplate to crank the engine.

- Overrunning Clutch (Bendix Drive): A one-way clutch mechanism that allows the pinion gear to engage the flywheel/flexplate for starting but disengages automatically once the engine starts and exceeds the starter motor's speed. This prevents the starter motor from being driven at excessively high speeds by the running engine, which would quickly destroy it.

- Solenoid (Integrated): As mentioned earlier, the solenoid often integrated directly onto the starter motor housing serves two crucial roles. It mechanically pushes the pinion gear into engagement with the flywheel/flexplate and simultaneously connects the high-current path from the battery to the starter motor.

Operation:

When the ignition switch is turned to the "start" position, a small current flows to the starter relay. The relay closes, sending power to the starter solenoid. The solenoid's electromagnet pulls a plunger, which performs two actions simultaneously:

- Pinion Gear Engagement: The plunger mechanically pushes a lever that extends the pinion gear forward, meshing it with the teeth of the flywheel or flexplate. This is a critical step, as proper engagement is essential for successful cranking.

- High-Current Connection: The plunger also closes a set of heavy-duty electrical contacts within the solenoid, completing the circuit between the battery and the starter motor. This allows a large current to flow through the starter motor's windings.

With power applied, the starter motor's armature begins to rotate rapidly. The interaction between the magnetic field (created by the field windings or permanent magnets) and the current flowing through the armature windings generates a powerful torque. This torque is transmitted through the pinion gear to the flywheel/flexplate, causing the engine's crankshaft to rotate. As the crankshaft turns, it drives the pistons, valves, and other engine components, initiating the combustion process.

Once the engine starts, it begins to spin faster than the starter motor. The overrunning clutch prevents the engine from driving the starter motor. When the ignition switch is released from the "start" position, the current to the solenoid is cut off. The plunger retracts, disengaging the pinion gear and disconnecting the battery from the starter motor. The starter motor comes to a stop, ready for the next start cycle.

Common Failure Points:

Like any mechanical and electrical device, the starter motor is subject to wear and tear. Here are some common causes of starter motor failure in the 2017 Nissan Titan:

- Worn Brushes: Over time, the carbon brushes wear down due to friction against the commutator. This reduces their ability to conduct current, leading to weak or intermittent starting. A telltale sign is a clicking sound without the engine turning over.

- Solenoid Failure: The solenoid is a high-stress component that can fail due to burned contacts, a weak electromagnet, or mechanical damage. This can prevent the starter motor from engaging or receiving power. Often a single click will be heard with no action from the starter.

- Overrunning Clutch Problems: The overrunning clutch can fail to engage or disengage properly. If it fails to engage, the pinion gear will not mesh with the flywheel, resulting in no cranking. If it fails to disengage, the starter motor will be driven at excessive speeds by the engine, leading to damage. Grinding noises are often a sign of this.

- Armature Problems: The armature windings can short circuit, open circuit, or become grounded. This can result in a complete failure of the starter motor or cause it to draw excessive current.

- Loose or Corroded Connections: Poor electrical connections can restrict current flow to the starter motor, resulting in weak starting or no starting at all. Corrosion on battery terminals, ground connections, or starter motor terminals is a common culprit.

- Flywheel/Flexplate Damage: Damaged or missing teeth on the flywheel or flexplate can prevent the pinion gear from engaging properly. This can result in a grinding noise or no starting.

- Battery Issues: Although technically not a starter motor issue, a weak or discharged battery is a very common cause of starting problems. A battery with insufficient voltage or amperage cannot provide the necessary power to crank the engine effectively. Always verify the battery's condition before diagnosing the starter itself.

Diagnosis and Testing:

Diagnosing a faulty starter motor requires a systematic approach. Here are some basic troubleshooting steps:

- Check the Battery: Verify the battery voltage and its ability to deliver sufficient amperage. A load test is recommended.

- Inspect Connections: Ensure that all electrical connections to the battery, starter motor, and ground are clean, tight, and free of corrosion.

- Listen for Sounds: Pay attention to any unusual sounds when attempting to start the engine. A clicking sound may indicate a solenoid problem, while a grinding sound may indicate a problem with the pinion gear or flywheel.

- Voltage Drop Test: Use a multimeter to measure the voltage drop across the starter motor circuit while cranking the engine. Excessive voltage drop indicates a problem with the wiring or connections.

- Starter Motor Test (Bench Test): Remove the starter motor from the vehicle and perform a bench test. This involves connecting the starter motor directly to a fully charged battery to observe its operation. A properly functioning starter motor will spin freely and engage the pinion gear forcefully.

Conclusion:

The starter motor in the 2017 Nissan Titan is a vital component responsible for initiating the engine's operation. Understanding its construction, operation, and common failure points is essential for effective troubleshooting and maintenance. By following a systematic diagnostic approach and utilizing appropriate testing methods, you can accurately identify and resolve starter motor problems, ensuring reliable starting performance for your Titan. Regular maintenance of the battery and electrical connections can significantly extend the lifespan of the starter motor and prevent many common starting issues. Remember safety first when working with electrical systems and always disconnect the battery before performing any repairs.