Tail Light Wiring Color Code

Understanding the tail light wiring color code is crucial for anyone working on vehicle electrical systems, whether you're replacing a bulb, installing a trailer hitch, or troubleshooting electrical issues. While there isn't a universally standardized color code across all vehicle manufacturers and models, there are common practices and guidelines that can significantly simplify the process. This article aims to provide a comprehensive overview of common tail light wiring color codes, best practices for identifying wires, and tips for safe and effective tail light wiring.

Why is Understanding Tail Light Wiring Important?

Tail lights are essential safety components on any vehicle. They provide vital signals to other drivers, indicating when you're braking, turning, or driving in reverse. Faulty tail lights can lead to accidents and even legal trouble. Knowing the tail light wiring color code allows you to:

- Correctly diagnose and repair wiring problems.

- Safely install aftermarket accessories like trailer lights or auxiliary lighting.

- Avoid short circuits and electrical damage that could affect other vehicle systems.

- Pass vehicle inspections that require properly functioning tail lights.

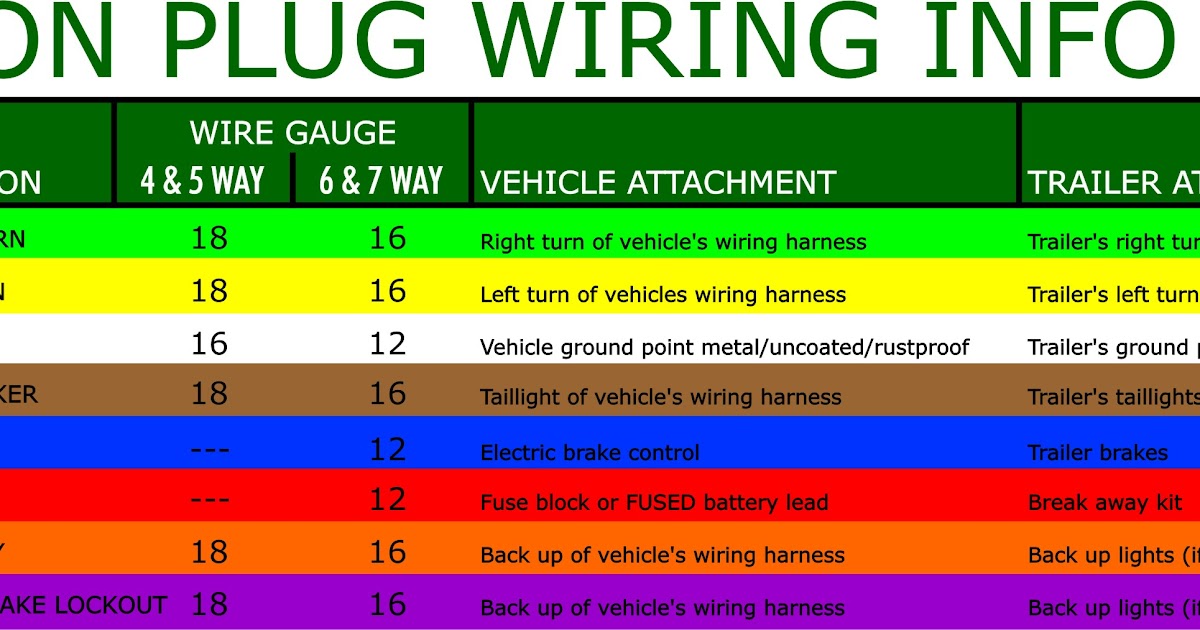

Common Tail Light Wiring Color Codes

As mentioned earlier, a globally consistent color code doesn't exist. However, some colors are more frequently used for specific functions than others. Keep in mind that these are general guidelines, and you should always verify the specific wiring diagram for your vehicle. Accessing the service manual is the best approach.

Ground Wire

The ground wire is almost universally black. It provides the return path for the electrical current and is essential for the proper functioning of the tail lights. It connects the circuit back to the vehicle's chassis, completing the electrical loop.

Brake Light Wire

Brake lights often use red or orange wiring. However, some manufacturers might use other colors, so always double-check. The brake light wire activates when the brake pedal is pressed, signaling to drivers behind you that you're slowing down or stopping. It's essential for safe driving and preventing rear-end collisions.

Turn Signal Wires

Turn signal wires are commonly yellow (left turn signal) and green (right turn signal). These wires activate the corresponding turn signal lights when the turn signal lever is engaged. They are crucial for communicating your intentions to other drivers and safely changing lanes or making turns.

Tail Light/Running Light Wire

Tail lights, also known as running lights, are typically wired with brown or blue wires. These lights illuminate whenever the headlights are on, making your vehicle visible during low-light conditions or at night. They enhance overall visibility and safety on the road.

Reverse Light Wire

The reverse light wire is often white or purple. This wire activates the reverse lights when the vehicle is shifted into reverse. Reverse lights not only provide illumination behind the vehicle but also serve as a warning to pedestrians and other drivers that you're backing up.

Identifying Wires When Color Codes are Unclear

Sometimes, the color codes may be faded, damaged, or simply non-standard. In such cases, you'll need to use other methods to identify the wires:

- Consult the Vehicle's Wiring Diagram: The most reliable way to identify wires is by consulting the wiring diagram for your specific vehicle make and model. These diagrams are usually found in the vehicle's service manual, which you can purchase online or from a dealership. Many websites also offer access to vehicle-specific wiring diagrams for a fee or subscription.

- Use a Multimeter: A multimeter is an essential tool for any automotive electrician. It can be used to test for voltage, continuity, and resistance. To identify tail light wires, you can use the multimeter to check for voltage when the corresponding function is activated (e.g., brake pedal pressed, turn signal engaged, headlights on).

- Test with a Circuit Tester: A circuit tester is a simpler and more affordable alternative to a multimeter. It uses a light bulb to indicate the presence of voltage. Connect the clip of the circuit tester to a known good ground and then probe each wire with the tester. When you activate a specific tail light function, the circuit tester will light up when probing the corresponding wire.

- Trace the Wires: Carefully trace the wires from the tail light assembly back to the connector. Sometimes, you can follow the wire's path and identify its function based on where it connects to other components in the vehicle's electrical system.

Tools and Materials Needed for Tail Light Wiring

Before you start working on your tail light wiring, make sure you have the necessary tools and materials:

- Wiring Diagram: Absolutely essential for accurate identification.

- Multimeter or Circuit Tester: For testing voltage and continuity.

- Wire Strippers: For removing insulation from wires.

- Wire Crimpers: For securely crimping connectors onto wires.

- Electrical Tape: For insulating and protecting wire connections.

- Wire Connectors: Butt connectors, spade connectors, or T-taps for making secure connections.

- Heat Shrink Tubing: For providing a waterproof and durable insulation for connections.

- Heat Gun: To shrink the heat shrink tubing.

- Screwdrivers and Pliers: For removing and installing tail light assemblies.

- Safety Glasses: To protect your eyes from debris.

- Gloves: To protect your hands from dirt and grease.

Safety Precautions

Working with electrical systems can be dangerous if you don't take proper precautions:

- Disconnect the Battery: Always disconnect the negative terminal of the battery before working on any electrical components to prevent short circuits and electrical shocks.

- Work in a Well-Lit Area: Ensure you have adequate lighting to see what you're doing clearly.

- Use Insulated Tools: Use tools with insulated handles to protect yourself from electrical shocks.

- Avoid Working in Wet Conditions: Water conducts electricity, so avoid working on electrical systems in wet conditions.

- Double-Check Your Connections: Make sure all connections are secure and properly insulated to prevent short circuits.

Step-by-Step Guide to Wiring Tail Lights

Here's a general guide to wiring tail lights. Remember to consult your vehicle's wiring diagram for specific instructions.

- Disconnect the Battery: As mentioned before, this is a crucial safety step.

- Remove the Tail Light Assembly: Use a screwdriver or socket wrench to remove the screws or bolts holding the tail light assembly in place. Carefully detach the assembly from the vehicle.

- Identify the Wires: Use the wiring diagram, multimeter, or circuit tester to identify the wires for each tail light function (ground, brake light, turn signal, tail light, reverse light).

- Connect the Wires: Using wire strippers, remove a small amount of insulation from the ends of the wires you need to connect. Use wire connectors (butt connectors, spade connectors, or T-taps) to securely connect the wires. Crimp the connectors tightly using wire crimpers.

- Insulate the Connections: Wrap each connection with electrical tape or use heat shrink tubing to insulate and protect the connections from moisture and corrosion. If using heat shrink tubing, slide the tubing over the connection and then use a heat gun to shrink the tubing tightly around the connection.

- Test the Lights: Reconnect the battery and test each tail light function to ensure it's working correctly. Have someone press the brake pedal, activate the turn signals, and shift the vehicle into reverse while you observe the tail lights.

- Reinstall the Tail Light Assembly: Once you've confirmed that all the lights are working properly, carefully reinstall the tail light assembly and secure it with the screws or bolts.

Troubleshooting Common Tail Light Problems

Here are some common tail light problems and how to troubleshoot them:

- Tail Light Not Working: Check the bulb first. If the bulb is good, check the fuse. If the fuse is blown, replace it with a fuse of the same amperage. If the fuse continues to blow, there may be a short circuit in the wiring. Use a multimeter to check for continuity between the wire and ground.

- Brake Light Not Working: Check the brake light switch, which is typically located near the brake pedal. Use a multimeter to check for voltage at the switch when the brake pedal is pressed. If there's no voltage, the switch may be faulty and need to be replaced.

- Turn Signal Not Working: Check the turn signal flasher relay. This relay is responsible for causing the turn signal lights to blink. If the relay is faulty, the turn signals may not work at all or may blink too quickly or too slowly.

- Dim Tail Lights: Dim tail lights can be caused by corroded connections, a weak ground, or a faulty voltage regulator. Clean the connections, check the ground connection, and test the voltage regulator with a multimeter.

Conclusion

Understanding tail light wiring color codes and basic electrical principles is invaluable for vehicle maintenance and repair. While specific color codes can vary, the information provided in this guide offers a solid foundation for troubleshooting, repairing, and installing tail light systems. Always prioritize safety by disconnecting the battery before working on electrical components and consulting the vehicle's wiring diagram for accurate information. If you're unsure about any aspect of tail light wiring, it's always best to consult a qualified automotive electrician to avoid causing further damage or injury. Remember, safe and properly functioning tail lights are essential for your safety and the safety of others on the road. By taking the time to understand the wiring and following best practices, you can ensure that your tail lights are working reliably and effectively.