Two Piece Rotors Vs One Piece

Braking. It’s the unsung hero of performance driving, often taken for granted until you desperately need it. And at the heart of your braking system lie the rotors, those shiny discs clamped down upon by the brake pads. But not all rotors are created equal. The debate between one-piece and two-piece rotors rages on, with each design offering distinct advantages and disadvantages. Understanding these differences is crucial for optimizing braking performance, whether you're chasing lap times or simply seeking enhanced safety on the road.

One-Piece Rotors: The Reliable Workhorse

One-piece rotors, as the name suggests, are manufactured from a single casting of iron or, less commonly, steel. This simple construction makes them cost-effective and robust, making them the default choice for most production vehicles. Their simplicity translates to reliability, as there are fewer components to fail or require maintenance. You'll find them on everything from economy cars to mid-range performance models.

Advantages of One-Piece Rotors:

- Cost-Effective: They are significantly cheaper to manufacture and purchase than two-piece rotors.

- Durability: Their simple construction makes them highly resistant to cracking and warping under normal driving conditions.

- Low Maintenance: Fewer components mean less to worry about in terms of maintenance and potential failure.

- Wide Availability: Readily available from most auto parts stores, both OEM and aftermarket.

Disadvantages of One-Piece Rotors:

- Heavier Weight: The solid construction contributes to a higher overall weight compared to two-piece designs. This increased weight adds to unsprung mass, which can negatively impact handling and suspension response.

- Limited Heat Dissipation: The single-piece design can hinder efficient heat dissipation, potentially leading to brake fade under extreme conditions.

- Less Performance Potential: While perfectly adequate for everyday driving, they may not be ideal for track days or high-performance applications where heat management is critical.

Consider, for example, a Honda Civic. Its factory-equipped rotors are almost certainly one-piece. These rotors are more than sufficient for daily commutes and the occasional spirited drive. However, if you were to modify that Civic for track use, upgrading to two-piece rotors would be a significant benefit.

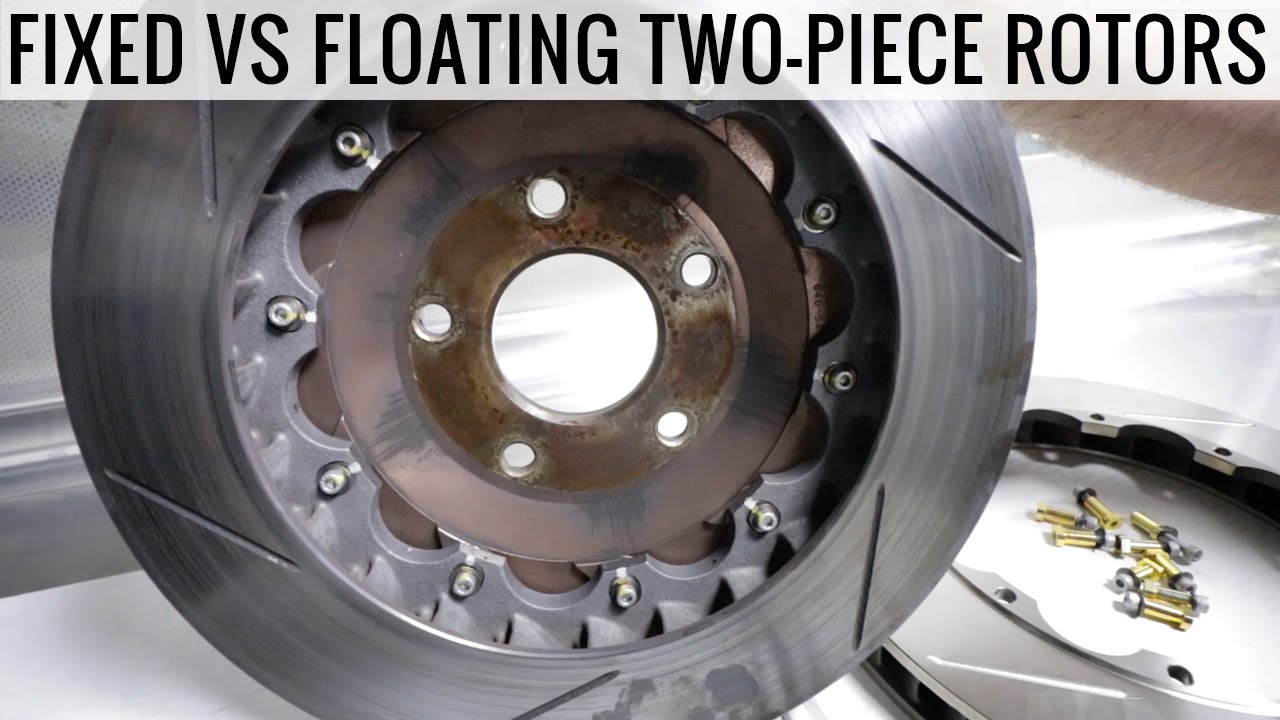

Two-Piece Rotors: Performance-Oriented Design

Two-piece rotors represent a step up in braking technology. They consist of two separate components: a rotor ring, typically made of high-carbon iron or steel, and a rotor hat or bell, usually constructed from aluminum. These two pieces are joined together, allowing for independent expansion and contraction as the rotor heats up and cools down. This design addresses many of the limitations of one-piece rotors, particularly in terms of weight and heat management.

Advantages of Two-Piece Rotors:

- Reduced Weight: The aluminum hat significantly reduces the overall rotor weight, lowering unsprung mass and improving handling.

- Improved Heat Dissipation: The separate design allows for better ventilation and heat transfer away from the braking surface, reducing the risk of brake fade.

- Reduced Thermal Stress: The independent expansion and contraction of the rotor ring and hat minimize thermal stress, reducing the likelihood of cracking or warping.

- Replaceable Rotor Rings: In some designs, the rotor ring can be replaced independently of the hat, reducing long-term replacement costs.

- Enhanced Aesthetics: Two-piece rotors often have a more visually appealing design, adding a performance look to your vehicle.

Disadvantages of Two-Piece Rotors:

- Higher Cost: They are significantly more expensive than one-piece rotors, both initially and potentially for replacement components.

- More Complex Construction: The more complex design introduces additional points of potential failure, requiring careful manufacturing and assembly.

- Maintenance Requirements: While some designs allow for rotor ring replacement, the overall maintenance can be more involved than with one-piece rotors.

- Potential for Noise: Some two-piece rotor designs can be prone to slight noise or vibration, particularly during initial braking.

Think of a Porsche 911 GT3, a car designed for serious track performance. It invariably comes equipped with two-piece rotors from the factory. The reduced weight and superior heat management are critical for maintaining consistent braking performance lap after lap. While a one-piece rotor could be installed, the performance trade-offs would be substantial.

Key Differences Summarized

The following table highlights the key differences between one-piece and two-piece rotors:

| Feature | One-Piece Rotor | Two-Piece Rotor |

|---|---|---|

| Cost | Lower | Higher |

| Weight | Heavier | Lighter |

| Heat Dissipation | Lower | Higher |

| Durability | High | Good (design dependent) |

| Maintenance | Low | Moderate |

| Performance | Adequate for everyday driving | Optimized for high-performance applications |

| Complexity | Simple | Complex |

Choosing the Right Rotor for Your Needs

Selecting the appropriate rotor type depends heavily on your driving style, vehicle application, and budget. Here’s a general guideline:

- Daily Drivers: For most daily drivers, one-piece rotors provide an excellent balance of cost, durability, and performance. Unless you regularly engage in aggressive driving or track days, upgrading to two-piece rotors is generally not necessary.

- Performance Vehicles: Performance vehicles, especially those driven on track, benefit significantly from two-piece rotors. The reduced weight and improved heat dissipation can dramatically improve braking performance and consistency.

- Modified Vehicles: If you've significantly increased your vehicle's horsepower or plan on track days, consider upgrading to two-piece rotors. They can handle the increased stress and heat generated by performance modifications.

- Budget Considerations: Factor in the initial cost, potential maintenance costs, and the long-term value proposition when making your decision. While two-piece rotors offer superior performance, they also come with a higher price tag.

Understanding Rotor Materials

Regardless of whether you choose one-piece or two-piece rotors, understanding the materials used in their construction is also important.

- Cast Iron: The most common material for brake rotors. It offers a good balance of cost, durability, and heat capacity.

- High-Carbon Iron: An improved version of cast iron with a higher carbon content, offering better heat resistance and reduced cracking. Often used in performance applications.

- Steel: Less common than cast iron, but can be used for rotors, particularly in applications where weight reduction is a priority.

- Ceramic: High-performance rotors made from ceramic composites offer exceptional heat resistance and weight savings, but come at a very high cost. Typically found on exotic sports cars.

- Aluminum: Used primarily for the rotor hat or bell in two-piece rotor designs due to its lightweight properties.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for maximizing the lifespan and performance of your brake rotors, regardless of the type. Here are some key tips:

- Follow Manufacturer's Instructions: Always adhere to the manufacturer's instructions for installation and torque specifications.

- Use Quality Brake Pads: Pair your rotors with high-quality brake pads designed for your driving style and vehicle.

- Proper Break-In Procedure: Follow a proper break-in procedure to bed in the brake pads and rotors. This helps to optimize braking performance and prevent premature wear.

- Regular Inspections: Inspect your rotors regularly for signs of wear, cracking, or warping.

- Cleanliness: Keep your rotors and brake pads clean of debris and contaminants.

- Torque Properly: Ensure lug nuts are torqued to the correct specification using a calibrated torque wrench.

Real-World Examples and Maintenance Costs

Consider a BMW 335i. A typical one-piece front rotor replacement might cost around $150-$250 per rotor, plus labor. Conversely, upgrading to a two-piece rotor setup could easily cost $500-$1000 per rotor, before labor. Furthermore, if only the rotor ring needs replacement on a two-piece system, the cost could be around $300-$600 per rotor. Labor costs will vary depending on your location and the mechanic's rates.

Another example: a Subaru WRX. Many owners upgrade to slotted or drilled one-piece rotors for improved aesthetics and slightly better bite. This is often a more cost-effective solution than opting for a full two-piece conversion, which can be significantly more expensive.

Conclusion

The choice between one-piece and two-piece rotors boils down to understanding your specific needs and priorities. One-piece rotors offer a reliable and cost-effective solution for everyday driving, while two-piece rotors provide a performance advantage for track days and high-performance applications. By carefully considering the advantages and disadvantages of each design, along with your driving style and budget, you can make an informed decision that optimizes your braking performance and ensures your safety on the road. Remember that proper installation and maintenance are crucial, regardless of the rotor type you choose.