What Are Drive Belts On A Car

Have you ever noticed a squealing sound coming from under the hood of your car, especially when you first start it up or when you turn on the air conditioning? Or perhaps your power steering feels unusually stiff? These could be signs of trouble with your car's drive belts. Let's dive into what drive belts are, what they do, and how to diagnose and fix potential problems.

What Are Drive Belts and Why Are They Important?

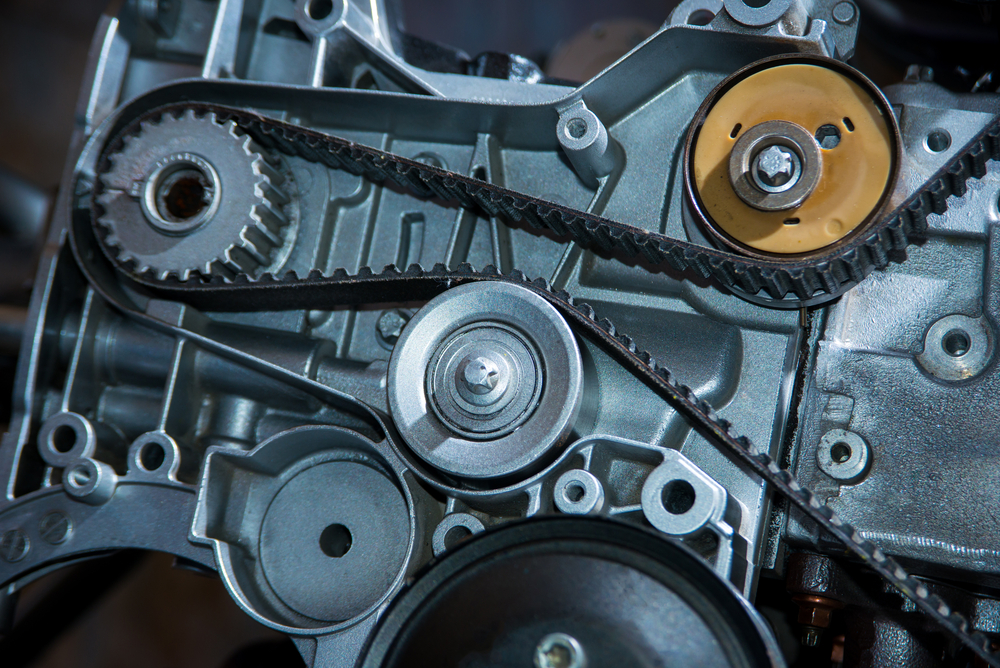

Drive belts, also sometimes referred to as serpentine belts or V-belts (though V-belts are becoming less common), are essential components that transfer power from the engine's crankshaft to various peripheral devices. Think of them as the engine's delivery system for getting power where it's needed.

Here's a breakdown of what these belts typically power:

- Alternator: This is crucial for charging the car's battery and powering the electrical system while the engine is running. A failing drive belt here can lead to a dead battery and a car that won't start.

- Power Steering Pump: This provides hydraulic assistance to make steering easier. A slipping or broken belt here results in very difficult steering, especially at low speeds.

- Air Conditioning Compressor: This is responsible for cooling the air inside your car. A broken belt here means no more cold air!

- Water Pump: In some vehicles, the water pump (which circulates coolant through the engine to prevent overheating) is driven by a belt. If this belt fails, your engine can overheat very quickly, potentially causing severe damage.

As you can see, these belts are vital for many of your car's most important functions. Ignoring problems with your drive belts can lead to much bigger, more expensive issues down the road.

Common Drive Belt Problems and Symptoms

Drive belts are made of rubber, which naturally degrades over time due to heat, friction, and exposure to the elements. Here are some common problems you might encounter:

- Cracking and Wear: This is the most common issue. Look for small cracks, especially on the ribbed side of the belt. Excessive wear can also thin the belt, reducing its grip and efficiency.

- Glazing: The belt surface can become smooth and shiny, reducing friction and causing slippage. This is often caused by oil or other contaminants.

- Squealing or Chirping Noises: This is a classic symptom of a slipping belt. The noise is usually most noticeable when the engine is first started or when accessories like the AC are turned on, putting extra load on the belt.

- Looseness: Belts can stretch over time, becoming loose and causing slippage. This can also be caused by a faulty tensioner pulley.

- Complete Breakage: This is the most dramatic failure. If a belt breaks, you'll likely lose power steering, air conditioning, and potentially experience overheating. Your car may also not start if the alternator belt is the one that failed.

Diagnosing Drive Belt Problems

Here's how you can diagnose potential drive belt issues:

- Visual Inspection: This is the first and easiest step. Open the hood and visually inspect all the drive belts. Look for cracks, wear, glazing, or missing chunks of rubber. A flashlight can be helpful to get a good look.

- Listen Carefully: Pay attention to any unusual noises coming from the engine compartment, especially squealing, chirping, or a rhythmic thumping sound. When does the noise occur? Is it constant or intermittent? Does it change with engine speed or when you turn on accessories?

- Check Belt Tension: You should be able to deflect the belt slightly (about 1/4 to 1/2 inch) between the pulleys. If it feels too loose, the belt may be stretched or the tensioner pulley may be failing. Many auto parts stores sell a belt tension gauge that provides a more accurate measurement.

- Consider Mileage and Age: Most manufacturers recommend replacing drive belts every 60,000 to 100,000 miles, or every 5 to 7 years, whichever comes first. Check your owner's manual for specific recommendations for your vehicle. Even if the belts look okay, replacing them proactively can prevent a breakdown later on.

Solutions: Replacing or Tightening Drive Belts

The solution to drive belt problems usually involves either tightening or replacing the belt. Here's a breakdown of both:

Tightening a Drive Belt

In some older vehicles, belt tension can be adjusted manually. However, most modern cars use an automatic tensioner pulley. If your vehicle has a manual tensioner, you can usually loosen the tensioner bolt and adjust the pulley to increase belt tension. Be careful not to overtighten the belt, as this can damage the pulleys and bearings.

Tools Needed: Wrench set, socket set.

Important Note: If your vehicle has an automatic tensioner, you cannot manually tighten the belt. If the belt is loose, the tensioner itself may be faulty and need replacement.

Replacing a Drive Belt

Replacing a drive belt is a relatively straightforward repair, but it's important to follow the correct procedure. Here's a general overview:

- Safety First! Disconnect the negative battery cable before starting any work. This will prevent accidental electrical shocks.

- Locate the Belt Routing Diagram: This diagram shows how the belt is routed around the various pulleys. It's usually located on a sticker under the hood. If you can't find it, take a picture of the belt routing before removing the old belt.

- Release the Tension: Use a wrench or socket to rotate the tensioner pulley and relieve tension on the belt. Most tensioners have a square hole specifically designed for this purpose.

- Remove the Old Belt: Once the tension is released, you can easily slip the old belt off the pulleys.

- Install the New Belt: Route the new belt around the pulleys according to the diagram, making sure it's properly seated in each groove.

- Release the Tensioner: Slowly release the tensioner pulley to apply tension to the new belt.

- Double-Check the Routing: Make sure the belt is properly seated on all the pulleys and that the routing is correct.

- Reconnect the Battery: Reconnect the negative battery cable.

- Start the Engine: Start the engine and listen for any unusual noises. Check the belt tension again after a few minutes of running.

Tools Needed: Wrench set, socket set, breaker bar (for stubborn tensioners), belt routing diagram (or a picture of the old belt routing).

Tip: When replacing a drive belt, it's a good idea to also inspect and replace the tensioner pulley and idler pulleys. These components can wear out over time and cause premature belt failure.

Cost of Repair

The cost of drive belt repair can vary depending on the vehicle, the type of belt, and whether you do the work yourself or take it to a mechanic.

- DIY: The cost of a new drive belt typically ranges from $20 to $50. If you need to replace the tensioner pulley or idler pulleys, add another $50 to $150 per component.

- Professional Repair: A shop will typically charge between $100 and $300 to replace a drive belt, including labor. If you need to replace the tensioner pulley or idler pulleys, the cost can be significantly higher.

Preventative Maintenance

The best way to avoid drive belt problems is to perform regular preventative maintenance. Here are a few tips:

- Regular Inspections: Inspect your drive belts regularly for signs of wear and tear.

- Proper Belt Tension: Ensure your drive belts are properly tensioned.

- Replace Belts Proactively: Replace your drive belts according to the manufacturer's recommendations.

- Address Leaks Promptly: Repair any oil or coolant leaks that could contaminate the belts.

By following these tips, you can keep your drive belts in good condition and avoid costly repairs down the road. If you're unsure about any aspect of drive belt maintenance, it's always best to consult with a qualified mechanic.

Remember, a little preventative maintenance can go a long way in keeping your car running smoothly and reliably!