What Does A Power Door Lock Actuator Do

So, you're diving into power door locks, eh? Good on you. It's a system that many take for granted until it fails, leaving you fumbling with keys. At the heart of this convenience lies the power door lock actuator. Let's break down what it does, how it does it, and some potential pitfalls along the way. Consider this your deep dive into the electromechanical heart of your vehicle's locking system.

The Core Function: Mechanical Motion from Electrical Signal

The fundamental purpose of a power door lock actuator is simple: to convert an electrical signal into mechanical motion. This motion is then used to physically lock or unlock your vehicle's door. Think of it as the muscle that obeys the brain (the car's electrical system). Instead of you manually pushing or pulling the lock lever, the actuator does it for you based on input from the door switch, remote key fob, or the car's security system.

However, that simplicity hides some clever engineering. The actuator needs to be reliable, durable, and relatively compact, all while delivering enough force to overcome the resistance of the door latch mechanism and any accumulated grime or corrosion. To understand how it accomplishes this, let's dissect a typical actuator.

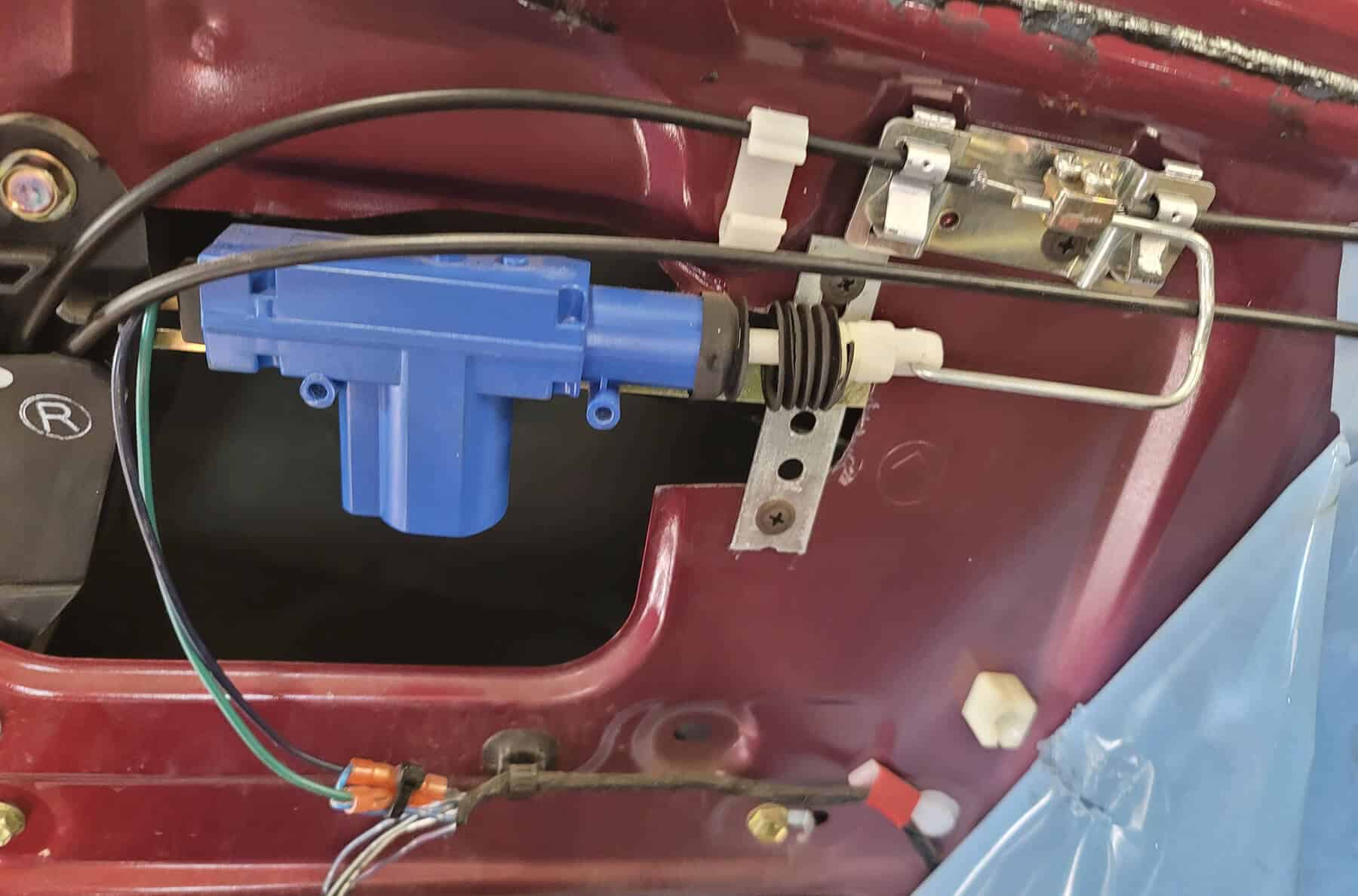

Internal Components: A Peek Inside

While designs vary slightly between manufacturers and models, the core components of a power door lock actuator remain consistent. Let's go through each component:

- Electric Motor: This is the engine of the operation. Typically a small, reversible DC (Direct Current) motor. Reversible means it can spin in both directions, which is essential for locking and unlocking. The motor's size and gearing are carefully selected to provide the necessary torque to move the locking mechanism. The motor generally operates on 12VDC from the car's electrical system.

- Gearbox: The motor alone doesn't have enough torque to directly manipulate the lock. A gearbox, often a series of small gears, steps down the motor's speed and increases its torque. This is crucial for applying the force needed to overcome the resistance in the locking mechanism. Think of it like using a wrench to tighten a stubborn bolt.

- Cam or Linkage: This converts the rotational motion from the gearbox into linear motion needed to move the lock lever or rod. A cam is a rotating or sliding piece (as a wheel or eccentric) in a mechanical linkage used especially in transforming rotary motion into linear motion or vice versa. A linkage will simply be a connection of rigid bars or beams connected by joints. This component directly interfaces with the door lock mechanism.

- Position Sensors (Optional but Increasingly Common): Some actuators incorporate sensors, such as potentiometers or Hall-effect sensors, to provide feedback to the vehicle's Body Control Module (BCM). This feedback allows the BCM to verify that the door is indeed locked or unlocked. It also enables features like auto-relock if a door isn't opened within a certain timeframe after unlocking. This is part of closed loop control.

- Electrical Connector: This is where the actuator connects to the vehicle's wiring harness, receiving power and ground signals from the door lock switch or the BCM. The connector's pinout is critical, so always refer to the vehicle's wiring diagram before disconnecting or reconnecting it.

How it Works: From Switch to Secure

Now, let's trace the path of the electrical signal and see how all these components work together:

- Signal Initiation: You press the power door lock switch on the door panel, use the remote key fob, or the car's security system sends a lock/unlock command.

- BCM Processing (Often): In modern vehicles, the signal often goes to the BCM. The BCM is like a central control unit for many of the car's electrical functions. It interprets the signal, checks for any safety interlocks (e.g., is the vehicle in gear preventing door lock activation?), and then sends the appropriate voltage to the correct door lock actuator(s).

- Actuator Activation: The actuator receives the voltage. The direction of the voltage determines whether the motor spins clockwise (locking) or counter-clockwise (unlocking).

- Mechanical Transformation: The electric motor spins the gearbox, increasing torque and reducing speed. The gearbox's output drives the cam or linkage, converting the rotational motion into the linear motion needed to move the door lock lever or rod.

- Lock/Unlock: The lever or rod physically engages or disengages the door latch mechanism, locking or unlocking the door.

- Feedback (If Equipped): If the actuator has a position sensor, it sends a signal back to the BCM confirming the lock/unlock status.

The magic lies in the reversible motor and the efficient transfer of energy from the motor to the mechanical lock. The gear ratios within the gearbox are crucial for providing the right balance of speed and torque. Too little torque, and the actuator won't be able to overcome resistance. Too much speed, and the lock mechanism might slam shut violently.

Common Problems and Troubleshooting

Power door lock actuators, like any mechanical component, can fail over time. Here are some common issues and how to approach troubleshooting them:

-

No Response: The door lock switch or remote doesn't activate the actuator at all. Check the following:

- Fuses: Always start with the fuses! A blown fuse is the most common cause of a complete failure. Consult your owner's manual for the location of the door lock fuse(s).

- Wiring: Inspect the wiring harness and connector leading to the actuator for any damage, corrosion, or loose connections. A multimeter can be used to check for voltage at the connector when the lock/unlock switch is activated.

- Door Lock Switch: The switch itself might be faulty. You can test the switch's continuity with a multimeter.

- BCM: Although less common, the BCM could be the culprit. This usually requires professional diagnostics.

-

Weak or Slow Response: The actuator struggles to lock or unlock the door, or it does so very slowly. Possible causes:

- Low Voltage: Check the voltage at the actuator connector. A significant voltage drop indicates a problem with the wiring or the BCM.

- Binding Mechanical Linkage: The door lock mechanism itself might be binding due to dirt, corrosion, or a bent linkage. Try lubricating the mechanism with a silicone-based lubricant.

- Worn Actuator Motor: Over time, the motor's brushes can wear down, reducing its performance. In this case, actuator replacement is usually necessary.

-

Intermittent Operation: The actuator works sometimes, but not others. This is often caused by:

- Loose Connections: A loose connection in the wiring harness can cause intermittent operation.

- Temperature Sensitivity: Sometimes, heat or cold can affect the actuator's performance. This might indicate a failing motor or a problem with the internal components.

- Clicking Sound: A clicking sound from inside the door panel when you try to lock or unlock the door usually indicates that the actuator motor is trying to work, but it's unable to move the lock mechanism. This could be due to a seized gearbox, a broken linkage, or a completely failed motor.

Important Safety Tip: Before working on any electrical components in your vehicle, disconnect the negative battery cable. This will prevent accidental short circuits and potential injury.

Replacement and Aftermarket Options

When an actuator fails, replacement is often the best solution. You have a few options:

- OEM Replacement: An Original Equipment Manufacturer (OEM) actuator is identical to the one that came with your vehicle. It's usually the most reliable option, but also the most expensive.

- Aftermarket Replacement: Aftermarket actuators are generally less expensive than OEM parts. However, quality can vary significantly. Choose a reputable brand with good reviews.

- Universal Actuators: These actuators are designed to fit a wide range of vehicles. They usually require some modification and wiring to install.

If you're considering an aftermarket or universal actuator, make sure it has the correct voltage rating, torque output, and physical dimensions for your vehicle. Read reviews and compare specifications before making a purchase.

Advanced Systems: CAN Bus Integration

Modern vehicles often integrate the power door lock system into the car's Controller Area Network (CAN) bus. In these systems, the BCM communicates with the door lock actuators digitally over the CAN bus. This allows for more sophisticated features, such as remote locking/unlocking via a smartphone app, anti-theft systems that automatically lock the doors when the vehicle is moving, and enhanced diagnostics.

Troubleshooting CAN bus-based door lock systems requires specialized diagnostic tools and a thorough understanding of the vehicle's electrical architecture. If you suspect a problem with the CAN bus, it's best to consult a qualified technician.

In conclusion, the power door lock actuator is a seemingly simple device that performs a vital function. Understanding its components, operation, and potential failure points can help you troubleshoot problems and keep your vehicle secure and convenient. Armed with this knowledge, you're well-equipped to tackle most power door lock issues. Happy wrenching!