What Gauge Is Car Sheet Metal

The unsung hero of automotive design, often overlooked in the shadow of roaring engines and sleek aesthetics, is the very skin that protects us: the sheet metal. But what gauge is car sheet metal, really? And more importantly, how is that gauge – that seemingly simple measurement of thickness – poised to evolve in the face of electrification, advanced materials, and the ever-increasing demands of safety and efficiency?

The Current State: A Balancing Act

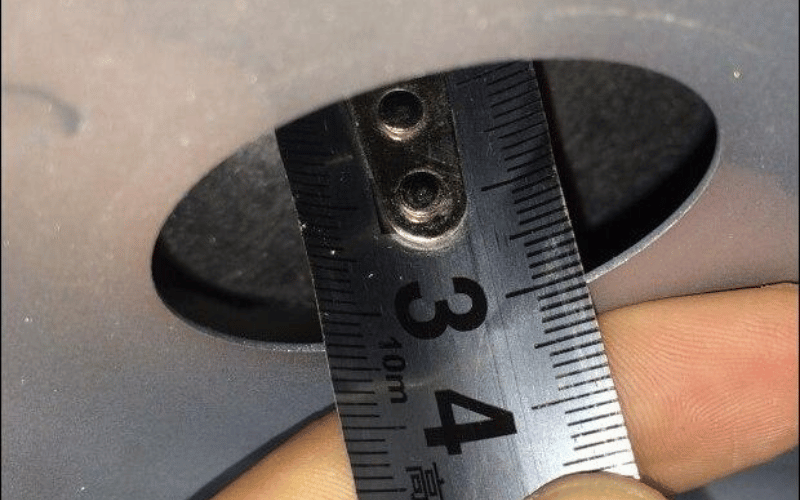

For decades, the answer to "what gauge is car sheet metal" has hovered around 18-22 gauge steel for most body panels. This translates to roughly 1.2 to 0.7 millimeters in thickness. This range represents a carefully struck balance: enough rigidity to provide structural integrity and impact resistance, while remaining light enough to not unduly burden fuel economy. Heavier gauge steel offers greater strength, but at the cost of increased weight, diminishing performance and fuel efficiency. Thinner gauges, while lighter, compromise safety and dent resistance.

However, this established paradigm is facing disruption. The automotive industry is undergoing a seismic shift, driven by stricter emissions regulations, the rise of electric vehicles (EVs), and the relentless pursuit of enhanced safety features. These forces are pushing manufacturers to rethink every aspect of vehicle design, and sheet metal is no exception.

The Challenge of Electrification

Electric vehicles present a unique set of challenges regarding sheet metal. While EVs eliminate the heavy internal combustion engine, they introduce a new heavyweight: the battery pack. These batteries, crucial for range and performance, add significant weight to the vehicle, directly impacting efficiency and handling. To mitigate this, automakers are under immense pressure to reduce weight elsewhere, and sheet metal is a prime target.

The key challenge lies in maintaining structural integrity and crashworthiness while significantly reducing weight. This necessitates a move beyond traditional steel towards advanced materials and innovative manufacturing techniques.

Beyond Steel: A Material Revolution

The answer to the weight reduction problem doesn't lie in simply thinning down existing steel. Instead, the automotive industry is increasingly turning to alternative materials:

- Aluminum: Already widely used in high-end vehicles, aluminum offers a significant weight advantage over steel. However, it's more expensive and requires specialized welding techniques.

- High-Strength Steel (HSS) and Advanced High-Strength Steel (AHSS): These steels are engineered to provide exceptional strength-to-weight ratios. They allow for thinner gauges without sacrificing structural integrity. This is becoming increasingly prevalent in modern vehicles.

- Carbon Fiber Reinforced Polymer (CFRP): This exotic material offers unparalleled strength and lightness but comes with a hefty price tag and complex manufacturing processes. While currently limited to high-performance vehicles and niche applications, advancements in manufacturing could make CFRP more accessible in the future.

- Magnesium Alloys: Even lighter than aluminum, magnesium alloys are showing promise, particularly for internal structural components. However, concerns about corrosion and cost need to be addressed.

The integration of these materials is not a simple one-to-one replacement. Automakers are increasingly employing multi-material construction, strategically using different materials in different parts of the vehicle to optimize strength, weight, and cost. For example, AHSS might be used in critical crash zones, while aluminum is used for body panels, and CFRP for specific structural components.

Smart Manufacturing: Shaping the Future

The choice of material is only half the equation. How that material is formed and joined is equally crucial. Advanced manufacturing techniques are playing a vital role in optimizing sheet metal design and production:

- Hydroforming: Using pressurized fluid to shape metal into complex geometries, hydroforming allows for stronger, lighter components with improved structural integrity.

- Laser Welding and Joining: These precise techniques create stronger, more durable welds with minimal heat distortion, crucial for joining dissimilar materials.

- Additive Manufacturing (3D Printing): While not yet widely used for large body panels, 3D printing offers the potential to create highly customized and complex sheet metal components with optimized strength-to-weight ratios. Imagine printing custom reinforcement structures within a panel, precisely where they are needed.

- Advanced Simulation and Modeling: Sophisticated computer simulations allow engineers to predict the behavior of different materials and designs under various stress conditions, optimizing designs for safety and efficiency before physical prototypes are even built.

The Impact of Smart Automotive Solutions

Beyond materials and manufacturing, the increasing integration of smart automotive solutions is indirectly impacting sheet metal design. Features like:

- Advanced Driver-Assistance Systems (ADAS): Systems like automatic emergency braking and lane departure warning can potentially reduce the severity and frequency of accidents, allowing for a re-evaluation of sheet metal thickness in certain areas. The reliance on these systems comes with a caveat, however. Public trust and regulatory frameworks must adapt to handle the responsibilities of automated driving.

- Connected Car Technology: Real-time data on road conditions and traffic patterns can be used to optimize vehicle performance and potentially avoid accidents, influencing future sheet metal design decisions.

- Over-the-Air (OTA) Updates: Constant software updates can improve the performance of ADAS and other safety systems, potentially extending the lifespan of existing sheet metal designs and improving overall vehicle safety.

However, relying solely on technology is a dangerous proposition. Redundancy in safety systems and robust structural design remain paramount. A balanced approach that combines technological advancements with proven engineering principles is essential.

Challenges and Considerations

The transition to lighter, stronger, and more sustainable sheet metal is not without its challenges:

- Cost: Advanced materials like aluminum and CFRP are significantly more expensive than traditional steel. This cost must be carefully managed to ensure that EVs and other vehicles remain affordable.

- Repairability: Repairing vehicles made with multi-material construction requires specialized training and equipment. This could lead to higher repair costs and longer downtime after accidents.

- Recyclability: Ensuring the recyclability of advanced materials is crucial for sustainability. Closed-loop recycling processes are needed to minimize environmental impact.

- Manufacturing Complexity: Working with dissimilar materials and advanced manufacturing techniques requires significant investment in new equipment and training.

Overcoming these challenges requires collaboration between automakers, material suppliers, research institutions, and governments. Investing in research and development, establishing industry standards, and promoting workforce training are crucial steps.

A Vision for the Future: Adaptive and Intelligent Skin

Looking ahead, the future of car sheet metal is not just about thinner gauges and lighter materials. It's about creating an adaptive and intelligent skin that dynamically responds to its environment. Imagine:

- Self-Healing Materials: Sheet metal that can automatically repair minor scratches and dents, extending the lifespan of the vehicle and reducing the need for costly repairs.

- Morphing Body Panels: Actively controlled body panels that can adjust their shape to optimize aerodynamics and fuel efficiency in real-time.

- Integrated Sensors: Sheet metal embedded with sensors that can monitor stress levels, detect damage, and provide early warnings of potential failures.

- Energy Harvesting: Body panels that can harvest solar energy or kinetic energy from vibrations, contributing to the vehicle's overall energy efficiency.

This vision may seem far-fetched, but the rapid pace of technological innovation suggests that it is within reach. The quest to answer "what gauge is car sheet metal" is evolving into a quest to create a smart, sustainable, and ultimately safer future for mobility. The humble sheet metal, once a passive barrier, is poised to become an active and integral part of the driving experience.