What Gauge Wire For Light Bar

So, you're adding a light bar to your truck, Jeep, or ATV? Excellent choice! Nothing beats extra visibility on the trail or job site. But before you start wiring everything up, let's talk about something crucial: wire gauge. Using the wrong gauge wire can lead to dim lights, burnt-out wiring, and even electrical fires. Nobody wants that! Think of it like plumbing – a tiny pipe can't deliver enough water, and a too-big pipe is just wasteful and might not connect properly. We need the "just right" size.

Understanding the Importance of Wire Gauge

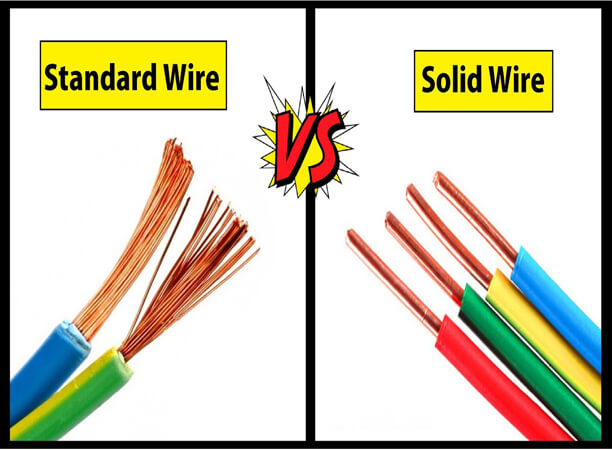

Wire gauge refers to the thickness of the wire itself. In North America, we typically use the American Wire Gauge (AWG) system. Smaller numbers indicate thicker wires. So, a 12-gauge wire is thicker than a 16-gauge wire. Thicker wires can handle more current (measured in amps) without overheating. When electricity flows through a wire, it encounters resistance. This resistance generates heat. If the wire is too thin for the amount of current flowing through it, it will overheat, potentially melting the insulation and causing a short circuit or fire. On the other hand, using wire that is much thicker than needed is perfectly safe from an electrical point of view, but it is unnecessarily expensive and could be difficult to manage due to it's larger size.

The Problem: Incorrect Wire Gauge

The most common problem we see is people undersizing the wire. They might think, "Hey, it's just a light bar, it doesn't need much." Wrong! Light bars, especially those powerful LED ones, can draw a significant amount of current. Undersized wire leads to several issues:

- Dim Light Output: The light bar won't shine as brightly as it should because it's not getting enough power.

- Overheated Wiring: You might notice the wires getting hot to the touch. This is a major warning sign!

- Blown Fuses: The fuse is designed to protect the circuit. If the wire is overheating, the fuse will blow repeatedly.

- Damaged Light Bar: In extreme cases, insufficient voltage can damage the light bar's internal components.

- Electrical Fires: This is the worst-case scenario. Overheated wiring can ignite nearby flammable materials.

The Solution: Choosing the Right Wire Gauge

So, how do you choose the right wire gauge? It's a three-step process:

- Determine the Amperage Draw: This is the most important step. Look for the light bar's wattage rating on the packaging or in the product specifications. Then, use Ohm's Law (Watts = Volts x Amps) to calculate the amperage draw. Since most automotive electrical systems operate at 12 volts (or 13.8 volts when the engine is running), the formula becomes: Amps = Watts / 12. For example, a 120-watt light bar will draw 10 amps (120 / 12 = 10). Always use the _maximum_ wattage rating of the lightbar for your calculations to be safe.

- Measure the Wire Length: This is the *total* length of the wire run, both positive and negative, from the power source (usually the battery) to the light bar and back to the ground. Don't just measure the distance in a straight line. Follow the actual route the wire will take, including any curves or bends. It's always better to overestimate slightly than to underestimate.

- Consult a Wire Gauge Chart: Once you know the amperage and wire length, you can consult a wire gauge chart. These charts are readily available online (just search for "wire gauge chart for 12v"). These charts will show you the recommended wire gauge for a given amperage and wire length. Be sure to use a chart that is for low voltage DC (Direct Current).

Here's a simplified example using a typical wire gauge chart:

Let's say your 120-watt light bar draws 10 amps, and the total wire length is 15 feet (7.5 feet to the light bar and 7.5 feet back to ground). A wire gauge chart might recommend 14-gauge wire for this application. For extra safety, especially if your runs are close to the maximum length for the chart's rating, you might consider going up to 12-gauge wire.

Pro Tip: When in doubt, it's always better to go with a thicker wire (smaller gauge number). It's better to be safe than sorry!

Tools and Materials Needed

Here's a list of tools and materials you'll likely need for wiring your light bar:

- Wire Strippers/Crimpers: For stripping the insulation off the wires and crimping connectors.

- Wire Cutters: For cutting the wire to the correct length.

- Electrical Tape or Heat Shrink Tubing: For insulating and protecting connections. Heat shrink tubing creates a more professional and durable connection.

- Connectors (Butt Connectors, Ring Terminals, Spade Connectors): For making secure connections to the battery, light bar, and ground.

- Fuse Holder and Fuse: To protect the circuit from overloads. Use a fuse with a slightly higher amperage rating than the light bar's calculated amperage draw.

- Wiring: Choose the correct gauge wire based on your calculations. Automotive-grade wire is recommended as it is more durable and resistant to heat and abrasion.

- Multimeter: For testing voltage and continuity.

- Zip Ties or Wire Loom: For organizing and protecting the wiring harness.

- Drill and Drill Bits (optional): For mounting the light bar and running wires.

- Screwdrivers and Wrenches: For tightening mounting hardware.

Practical Tips for a Successful Installation

- Always disconnect the battery before working on any electrical components. This prevents accidental short circuits.

- Use a fuse as close to the battery as possible. This provides the best protection for the entire circuit.

- Make clean, secure connections. Loose or corroded connections can cause voltage drop and other problems. Solder and heat shrink all connections for the highest quality connections.

- Protect the wiring harness with wire loom or zip ties. This prevents chafing and damage from the elements.

- Route the wiring away from moving parts and heat sources. This prevents damage to the wiring.

- Use a proper ground. A good ground connection is essential for proper operation. Scrape away any paint or rust to ensure a solid connection.

- Test your work thoroughly before hitting the road. Use a multimeter to check for voltage and continuity.

- Consider using a relay. If you plan to control the light bar with a switch, especially a small one, use a relay. The relay takes the load off the switch, preventing it from overheating or failing. Connect the low-current switch wiring to the relay and run a heavier gauge power wire from the battery to the relay and then to the light bar.

Troubleshooting Common Issues

Even with careful planning, you might encounter some issues. Here are a few common problems and how to troubleshoot them:

- Light bar is dim: Check the wire gauge, connections, and battery voltage. Make sure the ground is secure.

- Fuse keeps blowing: Check for short circuits in the wiring. Make sure the fuse is the correct amperage.

- Wiring is getting hot: The wire gauge is likely too small. Replace it with a thicker wire.

- Light bar doesn't turn on: Check the switch, fuse, relay (if used), and connections.

Approximate Repair Costs

The cost of wiring a light bar can vary depending on the complexity of the installation and the quality of the materials used. Here's a rough estimate:

- DIY Installation (Materials Only): $50 - $150. This includes the cost of wire, connectors, fuse holder, fuse, and other materials.

- Professional Installation: $150 - $500+. This includes the cost of labor and materials. The cost will depend on the shop's hourly rate and the complexity of the installation.

Remember, using the correct wire gauge is not just about getting the brightest light; it's about safety. Take the time to do your research, make accurate calculations, and use quality materials. If you're not comfortable working with electrical systems, it's always best to consult a qualified mechanic or electrician. Stay safe and enjoy your new light bar!