What Is An Automatic Seatbelt

The world of automotive safety has constantly evolved, with innovations aimed at reducing injuries and fatalities in the event of a collision. Among these innovations, the automatic seatbelt, also known as a motorized seatbelt or passive restraint system, played a significant role in the late 20th century. This article delves into the intricacies of automatic seatbelts, exploring their types, functionality, advantages, disadvantages, and eventual phasing out.

Understanding Automatic Seatbelts

An automatic seatbelt is a type of seatbelt system designed to automatically move into position around the occupant when the vehicle is started. Unlike conventional manual seatbelts that require the driver and passengers to actively buckle up, automatic seatbelts aim to increase seatbelt usage rates by removing the need for manual engagement. The underlying principle is simple: make safety passive and less reliant on driver/passenger compliance.

Types of Automatic Seatbelt Systems

There were primarily two distinct types of automatic seatbelt systems employed by automotive manufacturers:

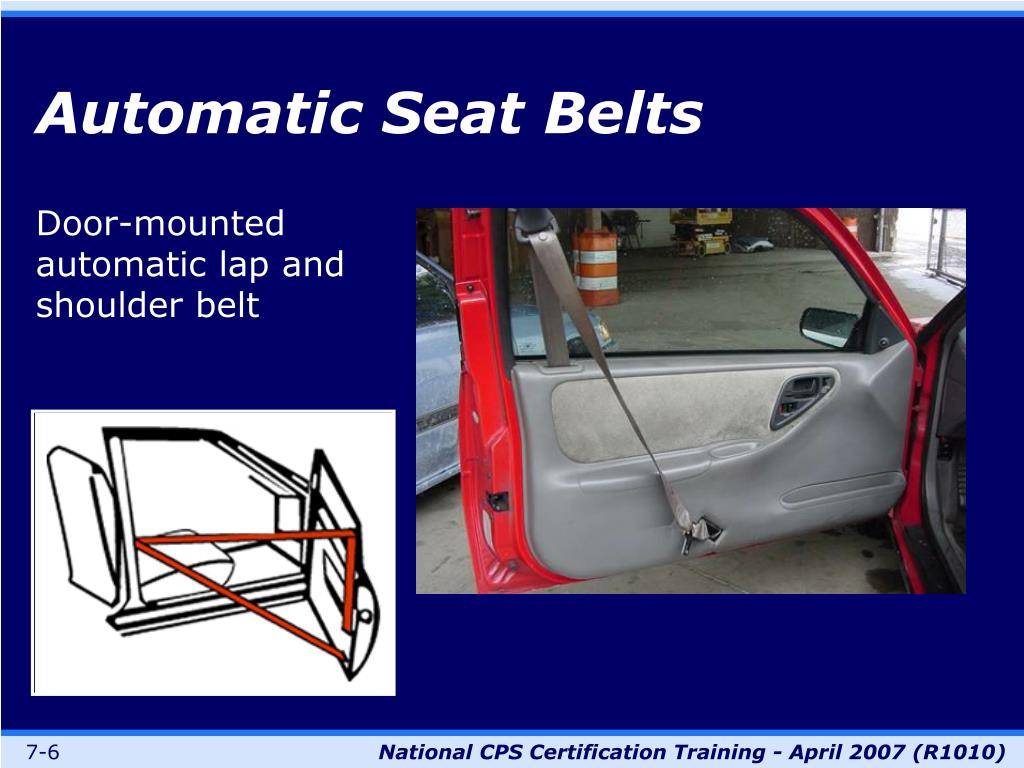

- Door-Mounted Automatic Seatbelts: These systems feature a shoulder belt that is attached to the vehicle's door. When the door is opened, the shoulder belt retracts along a track. Upon closing the door, a motor or mechanical linkage pulls the shoulder belt forward, positioning it across the occupant's chest. This design usually requires a separate manual lap belt that the occupant must buckle themselves. Examples of vehicles utilizing this system include certain models of the Honda Civic and Toyota Cressida.

- Motorized Track Systems: These systems utilize a shoulder belt attached to a motorized track along the door frame or B-pillar (the structural pillar behind the front door). When the ignition is turned on, the motor moves the shoulder belt forward, positioning it around the occupant. Some systems also incorporated a motorized lap belt, eliminating the need for any manual buckling. Vehicles like the Nissan Sentra and Hyundai Sonata (certain years) used variations of this track-based system.

How Automatic Seatbelts Work: A Deeper Dive

Let's examine the operational details of each system type more closely:

Door-Mounted Automatic Seatbelts

The door-mounted system leverages a relatively simple mechanical process. The shoulder belt is connected to a carriage that slides along a track integrated into the door panel. When the door is opened, a spring or small motor retracts the carriage, pulling the shoulder belt out of the way. When the door is closed, a linkage connected to the door mechanism engages, pulling the carriage forward and positioning the shoulder belt. The key components include:

- Shoulder Belt Assembly: The belt itself, made of durable webbing material.

- Carriage: The mechanism that holds the shoulder belt and slides along the track.

- Track: The guide rail built into the door, providing the path for the carriage to move.

- Linkage (Mechanical or Motorized): The connection between the door mechanism and the carriage, responsible for moving the belt.

- Retractor Mechanism: A spring-loaded or motorized device that retracts the belt when the door is opened.

Many of these systems used an inertia reel that would lock up during a sudden deceleration, preventing the occupant from moving forward. This is the same type of retractor used in standard manual seatbelts.

Motorized Track Systems

The motorized track system relies on an electric motor and control circuitry to manage the belt's movement. When the ignition is switched on, the control unit activates the motor, which drives a gear or cable connected to the shoulder belt's anchor point. This moves the anchor point along the track, positioning the belt across the occupant. Features include:

- Shoulder Belt Assembly: Similar to the door-mounted system, with durable webbing.

- Motor and Gearbox: The electric motor and gear reduction system providing the power to move the belt.

- Track: A rail, usually mounted along the door frame or B-pillar, guiding the movement of the belt's anchor point.

- Control Unit: Electronic module managing the motor's operation, often incorporating safety interlocks.

- Position Sensors: Sensors detecting the belt's position, ensuring correct operation and preventing malfunctions.

Some advanced motorized track systems included features like automatic adjustment based on seat position or occupant size. These systems often incorporated more sophisticated sensors and control algorithms.

Advantages of Automatic Seatbelts

The primary advantage of automatic seatbelts was their increased usage rate compared to manual systems. Several studies conducted during the peak of their popularity showed a significant increase in seatbelt compliance in vehicles equipped with automatic systems.

- Higher Usage Rates: Automatic seatbelts eliminated the need for conscious effort, resulting in higher usage rates, particularly among those who might otherwise neglect to buckle up.

- Increased Safety: Higher usage rates directly translated to reduced injuries and fatalities in accidents.

- Simplicity for Passengers: Particularly beneficial for passengers who may find manual seatbelts confusing or difficult to use.

Disadvantages and Criticisms

Despite their advantages, automatic seatbelts were not without their drawbacks and faced considerable criticism. These shortcomings ultimately contributed to their decline.

- "Mouse Trap" Effect: Door-mounted systems, in particular, were criticized for trapping occupants inside the vehicle in the event of an accident or emergency. If the door was damaged or jammed, the automatic shoulder belt could prevent quick egress.

- Manual Lap Belt Requirement: Many automatic systems only automated the shoulder belt, requiring occupants to still buckle a manual lap belt. If the lap belt was not used, the effectiveness of the shoulder belt was significantly reduced. This was often referred to as the "incomplete" protection.

- Reliability Issues: Automatic seatbelt systems, particularly motorized ones, were prone to mechanical and electrical failures. Motors could burn out, tracks could jam, and control units could malfunction, rendering the system inoperable.

- Complexity and Repair Costs: The added complexity of automatic systems increased manufacturing costs and made repairs more expensive and time-consuming compared to manual seatbelts. Diagnostic procedures were often complex, requiring specialized tools and knowledge.

- Nuisance Factor: Some users found the automatic movement of the seatbelt to be annoying or uncomfortable, particularly if the system was not properly adjusted.

- Safety Concerns in Specific Scenarios: There were concerns about the effectiveness of some systems in certain types of collisions, particularly side-impact crashes, where the single shoulder belt offered limited protection.

The Decline and Phase-Out of Automatic Seatbelts

The combination of the above disadvantages, along with advancements in manual seatbelt technology and the increasing prevalence of airbags, led to the gradual decline and eventual phase-out of automatic seatbelts. Key factors contributing to this decline include:

- Airbag Technology: The increasing adoption of airbags, particularly driver and passenger-side airbags, provided a more comprehensive level of protection in frontal collisions, reducing the perceived need for automatic seatbelts.

- Improved Manual Seatbelts: Advancements in manual seatbelt design, such as pretensioners and load limiters, improved their effectiveness and ease of use. Pretensioners automatically tighten the seatbelt in the event of a collision, while load limiters reduce the force exerted by the seatbelt on the occupant's chest.

- Legal and Regulatory Changes: Regulatory changes allowed automakers to prioritize airbags as the primary passive restraint system, reducing the pressure to implement automatic seatbelts.

- Consumer Preference: Ultimately, consumer preference shifted towards vehicles with more traditional manual seatbelts and airbags, influenced by concerns about reliability, cost, and the "mouse trap" effect.

By the late 1990s, most automakers had discontinued the use of automatic seatbelts in new vehicles. While some vehicles from the 1980s and 1990s equipped with automatic seatbelts remain on the road, these systems are increasingly becoming a maintenance challenge due to the age of the components and the scarcity of replacement parts.

Automatic Seatbelts Today: Maintenance and Considerations

For owners of vehicles equipped with automatic seatbelts, proper maintenance is crucial to ensure their continued functionality and safety. Key considerations include:

- Regular Inspections: Periodically inspect the seatbelt webbing, tracks, and motors for signs of wear, damage, or malfunction.

- Lubrication: Lubricate the tracks and moving parts of the system to ensure smooth operation. Use appropriate lubricants recommended by the vehicle manufacturer.

- Electrical System Checks: Inspect the wiring and connectors of motorized systems for corrosion or damage.

- Professional Service: If the system malfunctions, seek professional service from a qualified mechanic experienced in working with older vehicle systems. Avoid attempting repairs without proper knowledge and tools.

- Lap Belt Usage: Always ensure that the manual lap belt is properly buckled in conjunction with the automatic shoulder belt. The lap belt is essential for preventing submarining (sliding under the seatbelt) in a collision.

Automatic seatbelts represent a fascinating chapter in automotive safety history. While they ultimately proved to be a transitional technology, they played a valuable role in increasing seatbelt usage and highlighting the importance of passive safety systems.

While automatic seatbelts are largely a thing of the past, understanding their functionality and limitations provides valuable insight into the ongoing evolution of automotive safety technology. They serve as a reminder that safety solutions are constantly evolving, driven by technological advancements, regulatory changes, and consumer preferences.