What Is The Purpose Of The Turbocharger In The Vc-turbo Engine?

Alright, let's dive deep into the heart of the VC-Turbo engine and specifically, the role the turbocharger plays. If you're turning wrenches yourself, or even considering a performance upgrade, understanding this is crucial. We're not just talking about "more power," but how that power is generated and the nuances that come with it in a Variable Compression (VC) engine.

The Turbocharger: Forced Induction 101

Before we get VC-Turbo specific, let's recap what a turbocharger does in general. A turbocharger is essentially an air pump. Normal engines, known as naturally aspirated engines, rely on the vacuum created by the descending piston to suck air into the cylinder. The turbocharger forces more air into the cylinder than would naturally be drawn in. This is called forced induction.

Why is more air important? Because air needs fuel to burn. The more air you can cram into a cylinder, the more fuel you can burn, and the more power you can extract from each combustion event. Think of it like a bigger fire – more fuel, more air, bigger flames (or in this case, a more forceful push on the piston).

How it Works: The Nuts and Bolts

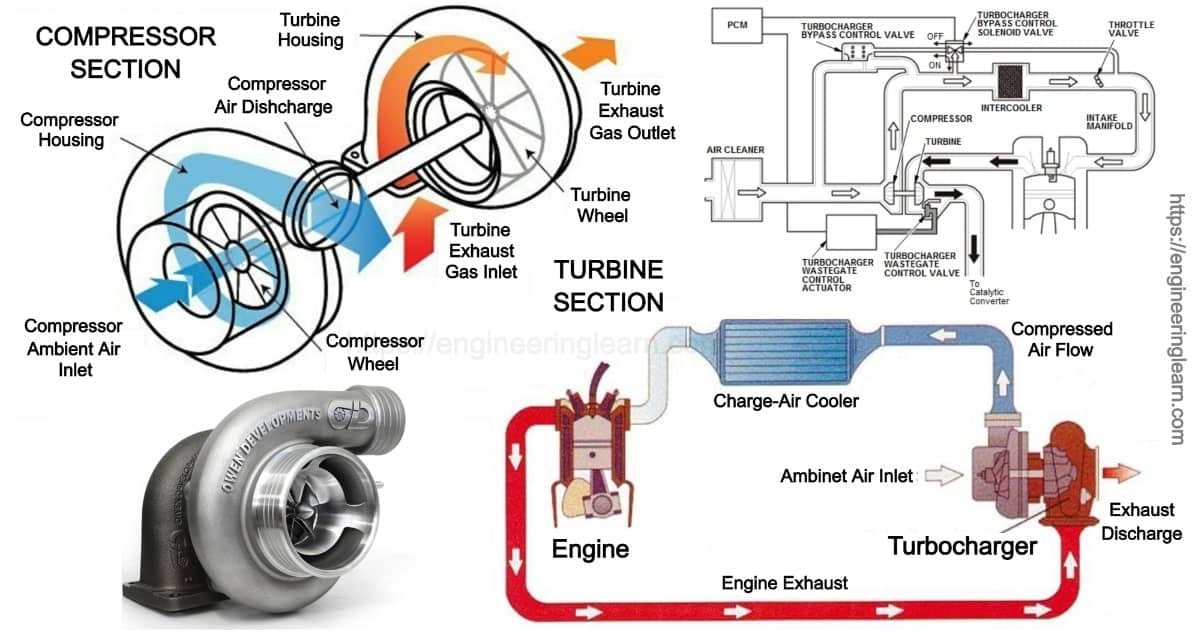

A turbocharger consists of two main parts connected by a shaft: the turbine and the compressor. The turbine is a small fan that sits in the exhaust stream. The hot exhaust gases exiting the engine spin the turbine. Because the turbine is physically connected to the compressor, the spinning turbine also spins the compressor.

The compressor is located in the intake path. As it spins, it sucks in ambient air, compresses it (hence the name), and forces that pressurized air into the engine's intake manifold. This higher-pressure air charge then enters the cylinders when the intake valves open.

The amount of pressure the turbocharger creates is called boost, usually measured in pounds per square inch (PSI) or bar. More boost generally means more power, but it also puts more stress on engine components.

Key Terms Recap:

- Naturally Aspirated: An engine that relies on vacuum to draw in air.

- Forced Induction: Using a turbocharger or supercharger to force air into the engine.

- Turbine: The part of the turbocharger spun by exhaust gases.

- Compressor: The part of the turbocharger that compresses intake air.

- Boost: The amount of pressure the turbocharger adds to the intake air.

The VC-Turbo Advantage: Where Things Get Interesting

Now we get to the VC-Turbo engine, and why the turbocharger's role is even more critical. The defining feature of the VC-Turbo engine is its ability to change its compression ratio on the fly. This is achieved by a complex multi-link system that alters the reach of the piston within the cylinder. Think of it like having an engine that can instantly switch between a high-compression performance engine and a low-compression fuel-efficient engine.

So, how does the turbocharger tie into this? The variable compression ratio dramatically expands the operating envelope where the turbocharger can efficiently and safely deliver power. Here’s how:

Low Compression Ratio: Boost-Friendly Performance

When the engine is under heavy load or when the driver demands maximum power (e.g., flooring the accelerator), the VC-Turbo engine lowers its compression ratio. A lower compression ratio makes the engine more tolerant of high boost levels. This is because a lower compression ratio reduces the risk of detonation (also known as engine knock or pinging). Detonation occurs when the air-fuel mixture ignites prematurely and uncontrollably, which can severely damage the engine.

With a lower compression ratio, the turbocharger can pump in a significantly higher volume of air without risking detonation. This translates directly to more fuel being burned, and therefore, more horsepower and torque.

High Compression Ratio: Efficiency and Responsiveness

When the engine is running under light load, such as cruising on the highway, the VC-Turbo engine increases its compression ratio. A higher compression ratio improves thermal efficiency. This means the engine extracts more energy from the fuel and wastes less energy as heat. This leads to better fuel economy.

You might be wondering, why not just run a high compression ratio all the time? Because high compression ratios are generally not compatible with high boost levels. However, at cruising speeds, the turbocharger might be providing very little to no boost. In these situations, the higher compression ratio maximizes efficiency. Furthermore, even when a *small* amount of boost is needed at higher compression, it will be available more quickly compared to naturally aspirated engines with no turbo. This enhances responsiveness.

The Turbocharger as a Compensator

The turbocharger also helps compensate for the compromises inherent in a variable compression design. While the VC system offers significant advantages, it adds complexity and potential points of failure. The turbocharger can mask some of the potential downsides of this complexity, ensuring smooth power delivery across the entire operating range.

VC-Turbo Specific Considerations: What to Watch Out For

Understanding the interaction between the turbocharger and the variable compression system is critical for maintenance and modifications. Here are a few points to keep in mind:

- ECU Tuning: The engine control unit (ECU) manages the complex dance between the variable compression system and the turbocharger. Any modifications to the turbocharger (e.g., a larger turbo or increased boost) require a proper ECU tune to ensure safe and optimal operation. Don't just slap on a bigger turbo and expect everything to work perfectly.

- Oil Quality and Changes: Turbochargers, especially in high-performance engines like the VC-Turbo, are incredibly sensitive to oil quality. The turbocharger bearings spin at extremely high speeds (often exceeding 100,000 RPM) and rely on clean, high-quality oil for lubrication and cooling. Regular oil changes with the correct type of oil are absolutely essential to prevent turbocharger failure. Synthetic oil is generally recommended.

- Intercooler Efficiency: The act of compressing air generates heat. Hot air is less dense and contains less oxygen, which reduces engine performance. An intercooler is a heat exchanger that cools the compressed air before it enters the engine. A more efficient intercooler can significantly improve the performance of a VC-Turbo engine, especially at higher boost levels. Consider upgrading your intercooler if you're planning to increase boost.

- Boost Leaks: Any leaks in the intake system (hoses, connections, etc.) can cause a loss of boost pressure, resulting in reduced performance and potentially damaging the engine. Regularly inspect all intake hoses and connections for cracks, leaks, or loose clamps.

In Conclusion

In the VC-Turbo engine, the turbocharger isn't just a bolt-on for extra power; it's an integral part of the overall engine management system. It works in concert with the variable compression system to provide a unique combination of performance, efficiency, and responsiveness. Understanding this interplay is key to properly maintaining, modifying, and appreciating the technology under the hood.