Where Is Clutch Fluid Located

For automotive professionals, a comprehensive understanding of hydraulic clutch systems is paramount. A crucial component of this system is the clutch fluid, the hydraulic medium responsible for transmitting force from the driver's foot to the clutch mechanism. Knowing its location, properties, and proper maintenance procedures is essential for ensuring smooth and reliable operation.

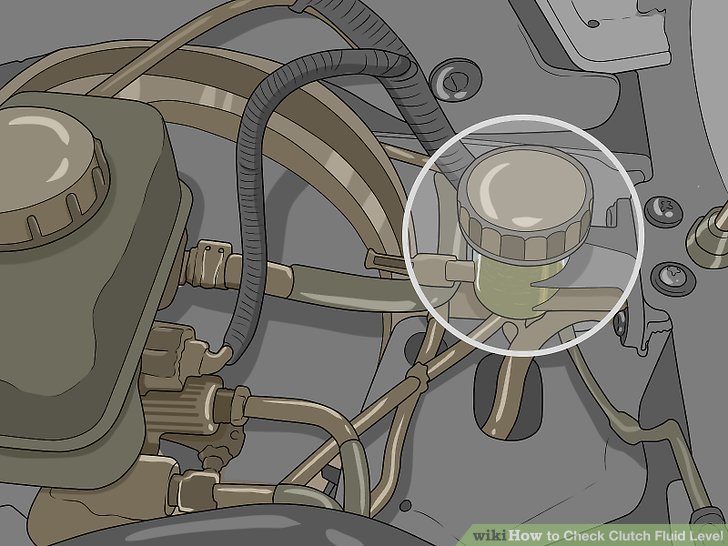

Location of Clutch Fluid Reservoir

The clutch fluid reservoir is typically located in the engine bay, often near the brake master cylinder reservoir. This proximity is due to the shared hydraulic principles and, in some cases, even shared fluid reservoirs. However, it's crucial to distinguish between the two, as using the wrong fluid or contaminating the brake fluid with clutch fluid can have catastrophic consequences. The clutch fluid reservoir is typically a small, translucent plastic container, allowing visual inspection of the fluid level and condition. The reservoir often has a cap labeled "Clutch Fluid" or with a symbol indicating the clutch system. Specific location varies by vehicle manufacturer and model.

In some older vehicles, particularly those with cable-operated clutches, a fluid reservoir will not be present. The absence of a hydraulic system eliminates the need for a working fluid, simplifying the system but also limiting the precision and feel compared to hydraulic clutches.

Technical Specifications and Engineering Choices

The type of fluid used in a hydraulic clutch system is critical for performance and longevity. DOT 3 and DOT 4 brake fluids are the most common fluids used in clutch systems, with DOT 4 offering a slightly higher boiling point for better performance under extreme conditions. DOT 5 fluid, a silicone-based fluid, is generally not recommended for clutch systems designed for DOT 3 or DOT 4 due to its incompatibility with certain seals and potential for air entrapment. Check the vehicle's service manual for the manufacturer's recommended fluid type.

Engineering choices in clutch fluid selection involve considering factors like temperature range, seal compatibility, viscosity, and hygroscopic properties. Brake fluids, including those used in clutch systems, are hygroscopic, meaning they absorb moisture from the atmosphere. Absorbed moisture lowers the boiling point of the fluid, increasing the risk of vapor lock, a phenomenon where vapor bubbles form in the hydraulic lines, preventing proper clutch disengagement. The higher boiling point of DOT 4 provides a greater margin of safety against vapor lock, making it suitable for vehicles subjected to heavy use or high temperatures.

Here's a breakdown of DOT 3 vs. DOT 4:

- DOT 3: Glycol-ether based. Lower boiling point than DOT 4. More affordable. Suitable for most standard applications.

- DOT 4: Glycol-ether based with borate esters. Higher boiling point. Better performance under high temperatures. Less prone to vapor lock. May be slightly more expensive.

The master cylinder and slave cylinder of the clutch system are designed with specific seal materials and tolerances to work optimally with the selected fluid. Using an incompatible fluid can cause seal swelling, degradation, or leakage, leading to clutch failure.

Real-World Performance and Alternatives

In real-world driving, the type and condition of clutch fluid directly impact clutch pedal feel and engagement. Fresh, clean fluid provides a firm, consistent pedal feel and precise clutch engagement. Contaminated or degraded fluid can result in a spongy pedal, inconsistent engagement, and difficulty shifting gears. The clutch performance suffers visibly with old clutch fluid.

Alternative clutch systems exist, although they are less common:

Cable-Operated Clutches

Pros: Simpler design, lower cost, less maintenance. Cons: Less precise feel, requires manual adjustment, susceptible to cable stretching and breakage, not suitable for high-performance applications.

Electronic Clutch Actuators

These replace the hydraulic system and are commonly found in automated manual transmissions (AMTs). Pros: Can be integrated with electronic control systems for smoother shifts and improved fuel efficiency. Cons: More complex system, greater reliance on electronic components, can be expensive to repair.

The hydraulic clutch system, when properly maintained, offers a balance of performance, reliability, and cost-effectiveness that makes it a popular choice for many vehicles.

Reliability Aspects and Maintenance Tips

The reliability of a hydraulic clutch system depends heavily on regular maintenance. Contaminated or degraded fluid is a major cause of clutch system failures. It is recommended to flush and replace the clutch fluid every 2-3 years or 30,000 miles, whichever comes first. More frequent changes may be necessary for vehicles subjected to heavy use or extreme conditions.

Here are some crucial maintenance tips:

- Regularly inspect the fluid level in the reservoir. Low fluid levels can indicate a leak in the system.

- Check the fluid for discoloration or contamination. Dark or cloudy fluid indicates degradation and the need for a flush.

- Use the manufacturer-recommended fluid type. Mixing different types of fluid can damage the system.

- Bleed the clutch system whenever the hydraulic lines are opened. This removes air bubbles that can cause a spongy pedal.

- Inspect the master and slave cylinders for leaks. Leaks can lead to fluid loss and clutch failure.

Ignoring clutch fluid maintenance can lead to several issues, including:

- Spongy clutch pedal.

- Difficulty shifting gears.

- Clutch slippage.

- Premature clutch wear.

- Complete clutch failure.

Future Trends

The automotive industry is rapidly evolving, with electrification and automation driving significant changes in powertrain technology. As electric vehicles (EVs) become more prevalent, the need for traditional clutch systems will diminish. EVs typically use single-speed transmissions or multi-speed transmissions with synchronized gear changes that do not require a clutch for driver interaction. Automatic transmissions and automated manual transmissions (AMTs) are also becoming more common in internal combustion engine (ICE) vehicles, reducing the reliance on manual clutches.

Despite the shift towards EVs and automatic transmissions, manual transmissions will likely remain available in some vehicles for enthusiasts and those who prefer the control and engagement of a manual gearbox. In these vehicles, hydraulic clutch systems will continue to be used, albeit with potential advancements in fluid technology and system design.

Future trends in clutch fluid technology may include the development of synthetic fluids with improved thermal stability, reduced hygroscopic properties, and enhanced seal compatibility. These advancements could extend the service life of clutch fluid and improve the reliability of hydraulic clutch systems.

Forward-Looking Note

While the role of manual transmissions and hydraulic clutch systems may diminish in the long term, understanding the principles and maintenance of these systems remains essential for automotive professionals. As the automotive industry transitions towards new technologies, a solid foundation in traditional automotive systems will be invaluable for diagnosing and repairing vehicles of all types. Embracing continuous learning and adapting to new technologies will be crucial for success in the evolving automotive landscape. The knowledge of hydraulic systems, irrespective of their eventual redundancy in certain applications, will remain foundational knowledge for automotive technicians as they transition to electric and other novel powertrain solutions.