Where Is The Intake Manifold Located

The intake manifold is a crucial component of your car's engine, responsible for delivering air to the cylinders where it mixes with fuel for combustion. Understanding its location and function is key to diagnosing potential engine problems and performing basic maintenance. But where exactly is this important part hiding?

Finding the Intake Manifold: A General Guide

In most modern gasoline engines, the intake manifold is located on top of the engine, usually right next to the engine block. It's typically a large, oddly shaped component made of aluminum or plastic, often with several tubes or runners branching off from a central plenum. These runners lead to each individual cylinder's intake port. Think of it as a sophisticated air distribution system for your engine.

However, specific placement can vary greatly depending on the engine configuration. Here's a breakdown of common locations based on engine type:

Inline Engines: Straightforward Placement

For engines with cylinders arranged in a straight line (inline-4 or inline-6), the intake manifold is generally found on one side of the engine, typically the side opposite the exhaust manifold. For example, in many older BMW inline-6 engines, like those found in the E36 325i or E46 330i, the intake manifold is prominently visible on the driver's side of the engine bay (in left-hand drive vehicles). The exhaust manifold would be on the passenger side.

The simplicity of the inline engine design often makes the intake manifold relatively easy to identify. Look for the large, usually black or silver component with multiple hoses and vacuum lines connected to it. It will be bolted directly to the cylinder head.

V-Engines: More Complex Arrangements

V-shaped engines (V6, V8, V12) present a slightly more complex layout. Due to the cylinder banks being angled apart, the intake manifold is often located between the banks, sitting in the "valley" of the V. This design allows for a more compact engine package.

Consider a Ford Mustang GT with a 5.0L Coyote V8. The intake manifold sits directly on top of the engine, nestled between the two cylinder banks. This placement is common in many V-engines, although some designs may feature individual intake manifolds for each cylinder bank, particularly in high-performance applications.

In some cases, older V-engines might have the intake manifold located on the outside of the cylinder heads, but this is less common in modern designs. These designs are sometimes called "cross-ram" intakes.

Flat Engines: A Unique Layout

Engines with horizontally opposed cylinders (flat-4 or flat-6), such as those found in many Subaru and Porsche models, have a unique intake manifold arrangement. In a Subaru WRX with a flat-4 engine, for instance, the intake manifold is typically split into two sections, one for each bank of cylinders. These manifolds are usually located on top of the engine, but the overall layout can be more intricate due to the engine's unique configuration.

Understanding the Intake Manifold's Function

Beyond just knowing its location, it's helpful to understand the intake manifold's function. The intake manifold is more than just a tube that carries air; it's designed to distribute air evenly to all cylinders and, in some designs, to optimize airflow for increased performance.

Here's a simplified breakdown:

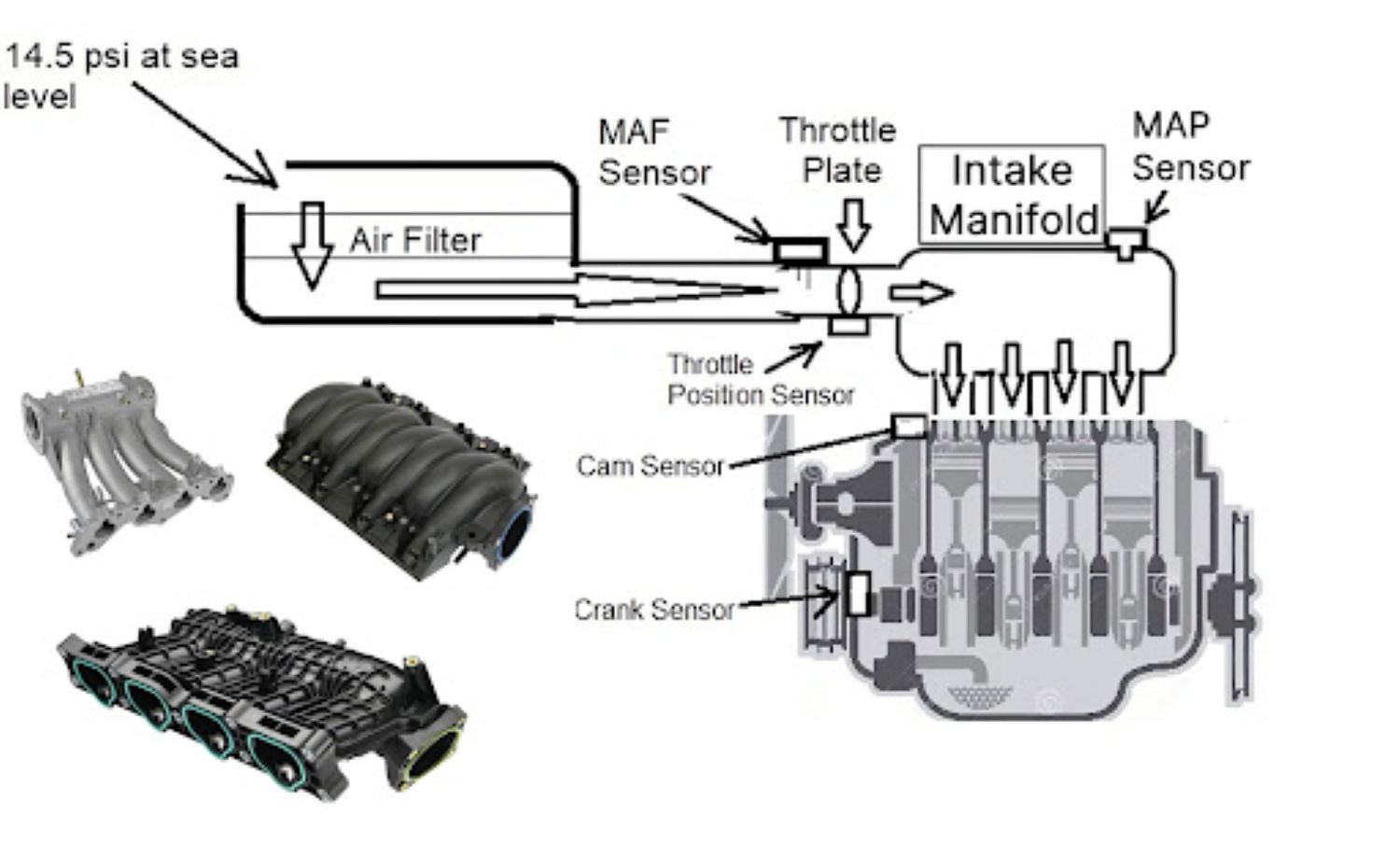

- Air Intake: The process begins with air being drawn into the engine through the air filter and often through a mass airflow (MAF) sensor that measures the amount of air entering the engine.

- Throttle Body: The air then passes through the throttle body, which controls the amount of air entering the intake manifold. The throttle is controlled by the accelerator pedal.

- Plenum: The intake manifold usually has a central plenum, a chamber that acts as a reservoir, ensuring a consistent supply of air. Think of it as a holding tank for air.

- Runners: From the plenum, individual runners (tubes) extend to each cylinder's intake port. The length and shape of these runners can significantly impact engine performance, particularly torque and horsepower at different RPMs. Shorter runners generally favor high-RPM power, while longer runners tend to boost low-end torque.

- Fuel Injection: In modern fuel-injected engines, fuel injectors are often located near the intake ports, either within the intake manifold itself or directly injecting fuel into the cylinder. This precise fuel delivery ensures optimal combustion.

Some intake manifolds, particularly those in performance vehicles, incorporate variable geometry or runner control valves. These systems adjust the length or configuration of the intake runners to optimize airflow for different engine speeds, improving both low-end torque and high-end horsepower. Examples of cars with variable intake geometry include older Acura Integra Type R models which made use of dual-stage intake manifolds, and BMW M cars.

Materials and Design Considerations

Intake manifolds are typically made from either aluminum or plastic. Aluminum manifolds are more durable and offer better heat dissipation, making them popular in high-performance applications. Plastic manifolds are lighter and less expensive to manufacture, and they can also reduce heat soak (the transfer of heat from the engine to the intake air), which can improve performance. However, plastic manifolds can be more susceptible to cracking or damage over time, especially in harsh engine environments.

The design of the intake manifold is crucial for engine performance. Engineers carefully consider the shape, length, and diameter of the runners to optimize airflow and ensure that each cylinder receives an equal amount of air. Computational fluid dynamics (CFD) software is often used to simulate airflow within the manifold and identify potential areas for improvement. Even small changes in design can yield significant gains in horsepower and torque.

Troubleshooting Intake Manifold Problems

A faulty intake manifold can cause a variety of engine problems. Common symptoms include:

- Vacuum Leaks: This is perhaps the most common issue. Cracks or leaks in the manifold, gaskets, or associated hoses can allow unmetered air to enter the engine, disrupting the air-fuel mixture and leading to rough idling, poor acceleration, and a check engine light. A tell-tale sign is a hissing sound coming from the engine bay.

- Reduced Performance: A clogged or damaged intake manifold can restrict airflow, reducing engine power and fuel economy.

- Misfires: If one or more cylinders are not receiving enough air or fuel, it can cause misfires, resulting in a rough-running engine and a flashing check engine light.

- Check Engine Light: Various issues with the intake manifold or related sensors can trigger the check engine light. Scanning the OBD-II system will reveal diagnostic trouble codes (DTCs) that can help pinpoint the problem.

Diagnosing intake manifold problems often involves visual inspection for cracks or leaks, a vacuum leak test using a smoke machine, and checking the integrity of gaskets and hoses. In some cases, replacing the intake manifold gasket or the entire manifold may be necessary.

Practical Takeaways for Car Owners and Enthusiasts

- Locate Your Intake Manifold: Familiarize yourself with the location of the intake manifold in your vehicle. Consult your owner's manual or a repair manual for specific details.

- Inspect Regularly: Periodically inspect the intake manifold and associated hoses for cracks, leaks, or damage. Pay close attention to the gaskets, as these are common sources of vacuum leaks.

- Listen for Hissing Sounds: Be alert for any unusual hissing sounds coming from the engine bay, which could indicate a vacuum leak in the intake manifold system.

- Use Proper Torque: When working on the intake manifold, always use a torque wrench to tighten bolts to the manufacturer's specifications. Over-tightening can damage the manifold or gaskets.

- Consider Upgrades: If you're looking to improve engine performance, consider upgrading to an aftermarket intake manifold. However, be sure to choose a manifold that is compatible with your engine and intended use. Research the potential gains and any necessary modifications beforehand.

- Clean the Throttle Body: A dirty throttle body can restrict airflow and affect engine performance. Cleaning the throttle body periodically can help maintain optimal engine operation. Consult your vehicle's repair manual for instructions on how to properly clean the throttle body.

By understanding the location, function, and potential problems associated with the intake manifold, you can better maintain your vehicle and address any issues that may arise. This knowledge empowers you to diagnose problems, perform basic repairs, and make informed decisions about upgrades or modifications.