Will A Bad Tps Cause No Start

So, your prized possession, that metal marvel you lovingly refer to as a car, has decided to stage a protest. You turn the key, the starter cranks with gusto, but… nothing. Just the echoing silence of unfulfilled combustion. The usual suspects flash through your mind: fuel pump, ignition coil, maybe even the dreaded computer. But have you considered a seemingly innocuous little sensor called the Throttle Position Sensor (TPS)? Can a bad TPS cause a no-start condition? The answer, as with most things automotive, is a resounding “it depends.”

Understanding the TPS and its Role

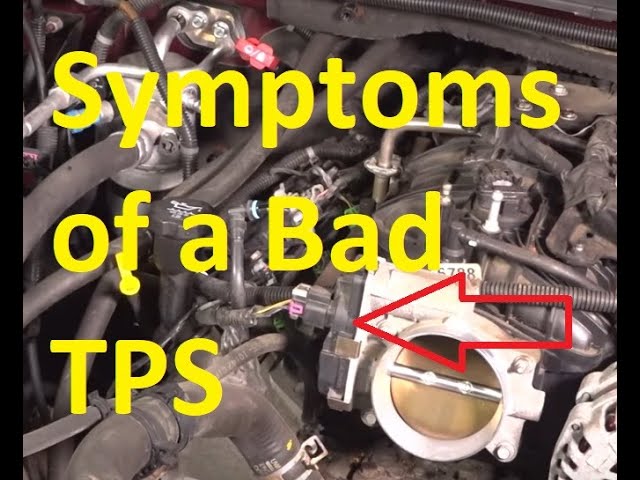

Before we dive into the specifics, let's quickly recap what the TPS actually does. Mounted on the throttle body, it monitors the position of the throttle plate, which controls the amount of air entering the engine. It sends this information as a voltage signal to the Engine Control Unit (ECU), allowing the ECU to determine the driver's demand for power and adjust fuel injection and ignition timing accordingly. Think of it as the ECU's eyes on your right foot.

How Failure Manifests

When a TPS goes bad, it can manifest in a variety of ways, ranging from subtle performance issues to a complete no-start situation. The key factor determining the severity is often the nature of the failure.

- Complete Failure (Open Circuit): If the TPS signal wire breaks or the sensor itself fails completely, the ECU may receive no signal or a wildly implausible reading. This can trigger a limp mode, severely restrict engine power, or in some cases, prevent the engine from starting altogether.

- Erratic Signal (Spiking or Dead Spots): The TPS signal may fluctuate erratically, causing the ECU to misinterpret the throttle position. This can lead to stumbling, hesitation, surging, or even stalling, particularly at low speeds or during idle.

- Incorrect Signal (Stuck or Out of Range): The TPS may be sending a signal, but it's inaccurate, either stuck at a particular value or outside the acceptable voltage range. This can lead to rich or lean fuel mixtures, poor performance, and potentially a no-start condition if the ECU interprets it as the throttle being completely closed (idle) or wide open.

Model-Specific Variations and Their Impact

The likelihood of a bad TPS causing a no-start varies significantly depending on the vehicle's make, model, and engine management system. Older vehicles with simpler systems are often more tolerant of minor TPS issues, while newer vehicles with sophisticated electronic controls are much more sensitive.

Classic Carbureted vs. Modern Fuel-Injected

With older, carbureted engines, a TPS failure is unlikely to cause a no-start because these systems don't rely on the TPS for fuel delivery or ignition timing. However, some older fuel-injected vehicles, particularly those from the early 1980s, might start but run poorly with a failing TPS, due to their less sophisticated ECU strategies. The symptoms might include very poor idle or rough running.

OBD-I vs. OBD-II Systems

Vehicles equipped with OBD-I (On-Board Diagnostics I) systems generally have fewer sensors and less sophisticated diagnostic capabilities than OBD-II vehicles. While an OBD-I system might detect a TPS failure, it might not provide as much detail about the specific problem, making diagnosis more challenging. Furthermore, older OBD-I vehicles may not immediately prevent the engine from starting. In contrast, OBD-II systems are designed to detect and diagnose a wider range of issues, and a critical TPS failure is more likely to trigger a Diagnostic Trouble Code (DTC) and potentially a no-start condition. The ECU may be programmed to prevent starting to protect the engine from potential damage due to incorrect fuel or ignition timing.

Drive-by-Wire vs. Traditional Throttle Cable

Vehicles with drive-by-wire systems (also known as electronic throttle control) are even more reliant on the TPS. In these systems, there's no direct mechanical linkage between the accelerator pedal and the throttle plate. Instead, the accelerator pedal position sensor sends a signal to the ECU, which then controls the throttle plate via an electric motor. A faulty TPS in a drive-by-wire system is more likely to cause a no-start, as the ECU relies heavily on accurate throttle position information to manage engine functions.

Spec Table: TPS Differences and No-Start Probability

| Vehicle Type | Engine Management | Throttle Control | No-Start Probability (Bad TPS) |

|---|---|---|---|

| Classic (Pre-1980s) | Carbureted | Throttle Cable | Low |

| Early Fuel-Injected (1980s) | OBD-I | Throttle Cable | Medium-Low |

| Modern Fuel-Injected (OBD-II) | OBD-II | Throttle Cable | Medium |

| Drive-by-Wire | OBD-II | Electronic Throttle Control | High |

Real-World Examples and Driving Impressions

Scenario 1: 1995 Honda Civic (OBD-I, Throttle Cable)

A failing TPS on this Civic primarily resulted in poor fuel economy and a noticeable dead spot in the throttle. The car would start and run, but acceleration was sluggish and uneven. Replacing the TPS resolved these issues, but it never prevented the car from starting.

Scenario 2: 2008 Ford Mustang (OBD-II, Throttle Cable)

This Mustang exhibited intermittent stalling and a rough idle. The OBD-II system flagged a TPS error code. While it rarely resulted in a complete no-start, the car was almost undriveable in stop-and-go traffic. Replacing the TPS cured the symptoms entirely.

Scenario 3: 2015 Toyota Camry (OBD-II, Drive-by-Wire)

A failing TPS on this Camry led to a complete no-start condition. The ECU detected the fault and prevented the engine from cranking. After replacing the TPS and clearing the DTCs, the car started immediately and ran perfectly.

Pros and Cons of TPS Replacement

- Pros:

- Relatively inexpensive part.

- Can significantly improve engine performance and fuel economy.

- Often a straightforward DIY repair.

- May resolve stalling, hesitation, and surging issues.

- Cons:

- Requires basic mechanical skills and tools.

- Calibration may be necessary after installation (depending on the vehicle).

- Incorrect diagnosis can lead to unnecessary repairs.

- Cheap aftermarket TPS sensors may not be as reliable as OEM parts.

Diagnosis is Key

Before you start tearing into your car, it's crucial to properly diagnose the issue. A diagnostic scan tool is your best friend here. Read the DTCs and research the specific codes related to the TPS. Pay attention to other symptoms the car is exhibiting, such as stalling, hesitation, or poor fuel economy. A multimeter can also be used to test the TPS voltage and resistance, but this requires a service manual and a good understanding of electrical circuits. Never blindly replace parts without proper diagnosis!

The Verdict: Can a Bad TPS Cause No Start?

While not always the culprit, a malfunctioning TPS can indeed lead to a no-start condition, especially in modern vehicles with drive-by-wire systems. The key is understanding your vehicle's specific technology and the nature of the TPS failure. Accurate diagnosis and a quality replacement part are essential for a successful repair.

Final Note: Some mechanics swear by calibrating the TPS after replacement, while others claim it's unnecessary on certain vehicles. What's your take? Do you calibrate every TPS, or do you only do it when required? Let the debate begin!