Wiring A 7 Pin Trailer Socket

The 7-pin trailer socket, a ubiquitous component in the automotive world, provides the essential electrical connection between a tow vehicle and a trailer. It’s more than just a simple plug; it's a carefully engineered interface designed to handle various electrical loads and signals critical for safe and legal towing. This article delves into the intricacies of wiring a 7-pin trailer socket, exploring the technical specifications, engineering choices, comparing it to alternatives, and considering long-term reliability and future trends.

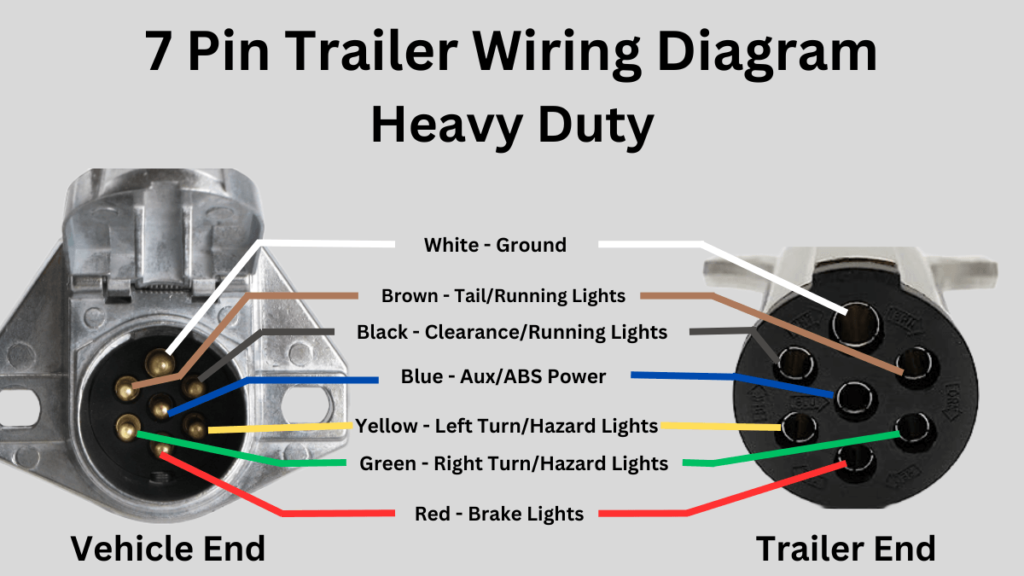

Understanding the 7-Pin Configuration

The 7-pin trailer socket utilizes a specific pinout configuration, standardized to ensure compatibility across different vehicle and trailer manufacturers. Deviations from this standard can lead to malfunctions and potentially dangerous situations. Let's examine the most common wiring configuration (SAE J560), used extensively in North America:

- Pin 1 (White): Ground

- Pin 2 (Blue): Electric Brake Controller Output

- Pin 3 (Yellow): Left Turn/Stop

- Pin 4 (Green): Right Turn/Stop

- Pin 5 (Brown): Tail/Running Lights

- Pin 6 (Red): Stop Lamps (can also be Auxiliary or 12V Power)

- Pin 7 (Black): 12V Power (Auxiliary or Battery Charge)

It’s crucial to verify the specific pinout diagram for the socket you are using, as variations do exist, especially in international markets. Using a multimeter to test the signals from the tow vehicle is highly recommended before connecting the trailer. Miswiring can damage the vehicle's electrical system and the trailer's components. Some 7-pin connectors may also incorporate weather seals and locking mechanisms to provide better protection against the environment, such as water or dust. Some manufacturers use molded plastic parts to improve weatherproofing and vibration resistance.

Wiring Techniques and Best Practices

Effective wiring starts with selecting the appropriate gauge of wire. The gauge is determined by the amperage draw of the circuits being connected. Using wire that is too small can cause overheating and voltage drop, leading to dim lights, weak brakes, and potential fire hazards. A typical recommendation is to use 12-gauge wire for the brake and auxiliary power circuits and 14-gauge wire for lighting circuits. However, always consult the trailer and brake controller manufacturer's specifications.

Proper termination is just as crucial as wire gauge. Crimp connectors offer a reliable connection when properly installed using a dedicated crimping tool. Soldering can also be used, but it requires skill and should be followed by heat shrink tubing to protect the joint from corrosion and provide mechanical strength. Avoid using wire nuts or Scotchlok connectors, as they are prone to failure in the harsh environment under a vehicle.

Route the wiring carefully, away from sharp edges, exhaust systems, and moving parts. Use zip ties or cable clamps to secure the wiring harness to the vehicle's frame. Protect the wiring with split loom tubing to provide additional abrasion resistance.

When connecting to the tow vehicle's wiring, avoid splicing into existing circuits whenever possible. Instead, use a dedicated trailer wiring harness that plugs directly into the vehicle's taillight connectors. These harnesses provide a clean and reliable connection without compromising the vehicle's original wiring.

Choosing the Right Socket Type

7-pin trailer sockets come in various materials, including plastic, metal, and hybrid designs. Plastic sockets are generally more affordable, but metal sockets offer greater durability and resistance to corrosion. Hybrid designs combine the best of both worlds, with a plastic body and metal pins.

Consider the environment in which the socket will be used. If the vehicle is frequently exposed to harsh weather or salt spray, a metal socket with corrosion-resistant coating is a better choice. Also, inspect the connector for proper seals to prevent water and debris from entering the contacts, which can lead to corrosion and electrical issues. The sealing mechanism is a critical design consideration for long-term performance.

Comparison with Alternatives

While the 7-pin connector is the most common, other options exist, including 4-pin flat connectors, 5-pin flat connectors, and 6-pin round connectors. The 4-pin connector is the simplest, providing only basic lighting functions (tail lights, brake lights, and turn signals). The 5-pin and 6-pin connectors add an auxiliary wire, often used for reverse lights or electric brakes.

Pros of 7-Pin Connector:

*Supports electric brakes and auxiliary power. *More robust and reliable than smaller connectors. *Standardized and widely compatible.

Cons of 7-Pin Connector:

*More complex wiring. *Can be more expensive than smaller connectors. *May require professional installation.

Compared to the 4-pin connector, the 7-pin offers significantly more functionality, making it essential for trailers with electric brakes or auxiliary power needs. While the 5-pin and 6-pin connectors offer some of the same advantages, they are less common and may not be compatible with all trailers.

Real-World Performance and Reliability

The reliability of a 7-pin trailer socket depends on several factors, including the quality of the materials, the wiring techniques used, and the environmental conditions. Corrosion is a common problem, especially in areas with high humidity or salt exposure. Regular inspection and maintenance are essential to prevent corrosion and ensure reliable performance.

Another potential issue is pin damage. The pins can be bent or broken if the connector is not handled carefully. Always align the connector properly before plugging it in, and avoid forcing it. Replacing damaged pins or the entire socket is often necessary to maintain a secure connection.

Vibration is a major factor that impacts connector durability. Poorly secured wiring can vibrate excessively, leading to premature failure of the connections. Proper routing and securing of the wiring harness are crucial to minimize vibration.

Maintenance Tips

Regular maintenance can significantly extend the life of a 7-pin trailer socket. Here are some tips:

- Inspect the socket and plug for corrosion, damage, and loose connections regularly.

- Clean the contacts with a wire brush or electrical contact cleaner.

- Apply dielectric grease to the contacts to prevent corrosion.

- Replace damaged pins or the entire socket as needed.

- Secure the wiring harness to prevent vibration.

- Check the ground connection to ensure it is clean and tight.

Preventive maintenance is much cheaper than replacing the entire wiring harness or dealing with electrical malfunctions while on the road. A small investment in time and materials can save significant headaches down the line.

Future Trends

The automotive industry is constantly evolving, and trailer wiring is no exception. Wireless trailer brake controllers are becoming increasingly popular, eliminating the need for a physical connection between the tow vehicle and the trailer's brakes. However, even with wireless brake controllers, a 7-pin connector or similar is still needed for lighting and other auxiliary functions.

Another trend is the integration of advanced driver-assistance systems (ADAS) with trailer towing. These systems can monitor the trailer's position and stability, providing warnings and corrective actions to prevent accidents. Integrating these systems may require more sophisticated communication protocols and wiring configurations.

The adoption of electric vehicles (EVs) will also impact trailer wiring. EVs have different electrical systems than traditional gasoline vehicles, and the charging needs of the trailer may need to be integrated into the vehicle's charging system. This could lead to the development of new connector types and wiring standards.

Conclusion

Wiring a 7-pin trailer socket is a critical task that requires careful attention to detail and adherence to best practices. By understanding the technical specifications, engineering choices, and maintenance requirements, automotive professionals can ensure safe and reliable towing for their customers. As the automotive industry continues to evolve, it's important to stay up-to-date on the latest trends and technologies in trailer wiring to provide the best possible service.

The future of automotive technology is undoubtedly electric and interconnected. The seemingly simple 7-pin connector will likely evolve into more sophisticated interfaces capable of handling higher data rates and power demands, facilitating advanced safety features and integrated vehicle-trailer control. Automotive professionals who embrace these changes will be well-positioned to thrive in the future.