Air Conditioning Gets Hot When Stopped

We've all been there: blasting the A/C on a hot summer day, only to be met with a wave of stifling heat the moment you pull into a parking spot and shut off the engine. This is a common issue that plagues many vehicles, and while it might seem like a minor annoyance, it can be a symptom of underlying problems in your car's air conditioning system. Understanding why this happens can save you money on unnecessary repairs and help you maintain a comfortable driving experience. This article will delve into the technical reasons behind this phenomenon, equipping you with the knowledge to diagnose and potentially address the issue yourself.

Background: The Automotive Air Conditioning System

Before we tackle the "hot air after shutdown" issue, let's quickly review the basics of your car's A/C system. Think of it as a closed-loop system using a refrigerant to transfer heat from inside the cabin to the outside environment. The main components include:

- Compressor: Driven by the engine via a belt, the compressor increases the pressure of the refrigerant (typically R-134a or the newer R-1234yf) and circulates it throughout the system. This compression significantly increases the refrigerant's temperature.

- Condenser: Located at the front of the car, often near the radiator, the condenser dissipates heat from the high-pressure, high-temperature refrigerant. Air flowing across the condenser fins helps to cool the refrigerant and turn it into a high-pressure liquid.

- Receiver-Drier (or Accumulator): This component filters and removes moisture from the refrigerant. Moisture in the system can lead to corrosion and ice formation, hindering performance. The receiver-drier typically sits on the high-pressure side of the system, while the accumulator is on the low-pressure side (used with orifice tube systems, see below).

- Expansion Valve (or Orifice Tube): This component reduces the pressure of the liquid refrigerant before it enters the evaporator. This pressure drop causes the refrigerant to rapidly cool and vaporize. Expansion valves are more common in newer vehicles, and provide a more efficient way to regulate refrigerant flow based on system demands. The orifice tube is a simpler, fixed-size restrictor, typically used in older or less expensive vehicles.

- Evaporator: Located inside the dashboard, the evaporator is where the cold refrigerant absorbs heat from the air blowing across it. The cold air is then channeled into the cabin vents, providing cooling. The refrigerant, now a low-pressure gas, returns to the compressor to start the cycle again.

Refrigerant: The Lifeblood of the System

The refrigerant is a crucial element. It undergoes phase changes (liquid to gas and vice-versa) to absorb and release heat. The specific refrigerant used matters. Mixing different types can cause serious damage. Always use the refrigerant specified by your vehicle manufacturer.

Technical Breakdown: Why the Heat Surge?

The heat you experience when you shut off your car's A/C is primarily due to the phenomenon known as heat soak. Here's a step-by-step breakdown:

- Refrigerant Equilibrium Disrupted: When the engine is running and the A/C is on, the compressor actively circulates the refrigerant, maintaining a relatively constant pressure and temperature gradient throughout the system. The condenser is efficiently shedding heat thanks to the airflow generated by the engine fan and vehicle movement.

- Engine Shutdown: When you turn off the engine, the compressor stops. The circulation of refrigerant halts immediately. The condenser no longer receives forced airflow.

- Heat Soak Occurs: The residual heat from the engine bay, exhaust manifold, and even the condenser itself (which still retains some heat from the last cycle) begins to soak into the surrounding components, including the refrigerant lines, the compressor, and particularly the condenser. Because there is no longer active cooling, the refrigerant in the condenser absorbs this heat, its pressure increases.

- Pressure Equalization and Temperature Increase: The pressure in the high-pressure side of the system (between the compressor outlet and the expansion valve/orifice tube) begins to equalize with the low-pressure side (between the evaporator outlet and the compressor inlet). This pressure equalization results in an overall increase in temperature within the evaporator core.

- Hot Air on Restart (Briefly): When you restart the car and turn the A/C back on, the air blowing through the vents initially passes over the now-warmer evaporator core. This results in a blast of hot air until the compressor can re-establish proper refrigerant circulation and the evaporator cools down again. This period is usually short, lasting from a few seconds to a minute or two, depending on ambient temperature, engine bay heat, and system efficiency.

Think of it like this: imagine a pot of water on a stove. While the burner is on, the water is actively boiling. When you turn off the burner, the water doesn't instantly stop boiling; it continues to simmer as it absorbs the residual heat from the stove. Similarly, the A/C system continues to "simmer" and equalize in temperature after the compressor stops.

Common Issues and Maintenance Concerns

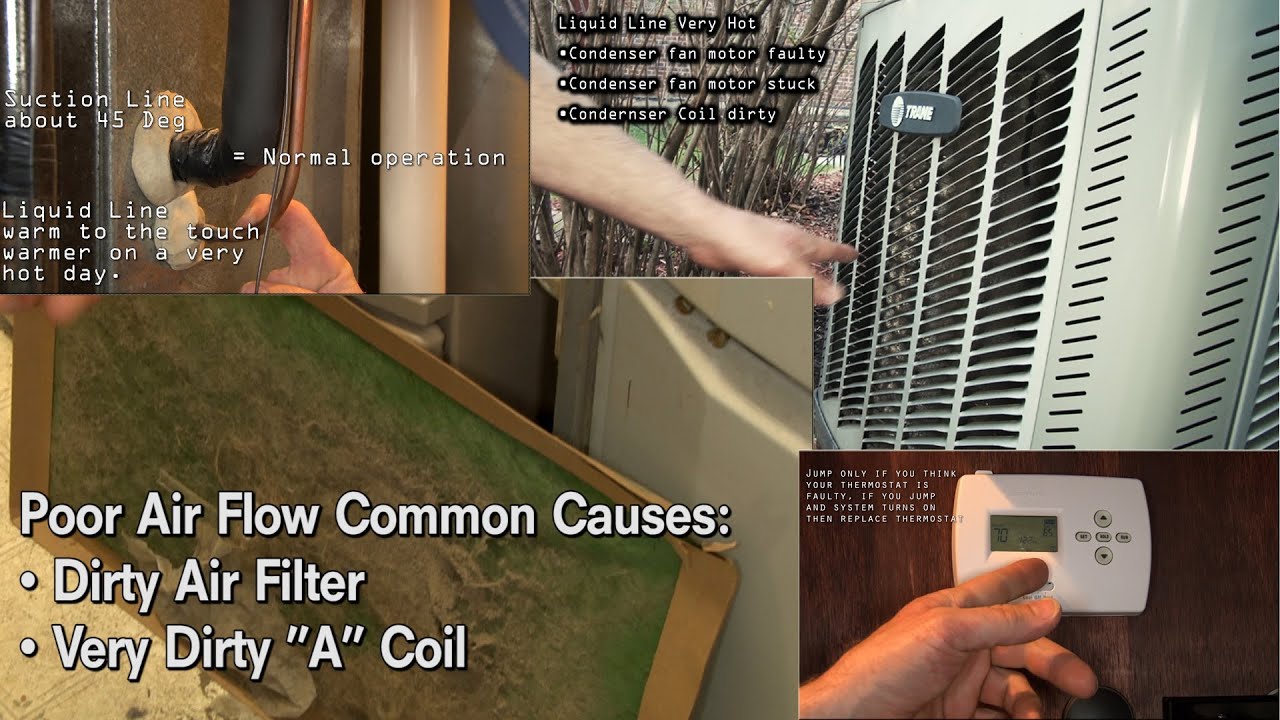

While heat soak is a normal phenomenon, its intensity can be exacerbated by other underlying issues. Addressing these can minimize the hot air blast after shutdown and improve overall A/C performance:

- Low Refrigerant Charge: An insufficient amount of refrigerant reduces the system's capacity to absorb and dissipate heat effectively. This can make the heat soak effect more noticeable and prolong the time it takes for the A/C to cool down after restart. Use a manifold gauge set to properly check the high and low side pressures while the system is running.

- Clogged Condenser Fins: Debris, dirt, and insects can accumulate on the condenser fins, hindering airflow and reducing its ability to dissipate heat. Regularly cleaning the condenser can significantly improve its efficiency. Use a fin comb to straighten bent fins for optimal airflow.

- Faulty Condenser Fan: Some vehicles have a dedicated condenser fan to provide airflow when the vehicle is stationary or moving slowly. If this fan is not functioning correctly, the condenser's ability to dissipate heat will be severely compromised, leading to increased heat soak. Use a multimeter to check the fan motor and relay.

- Restricted Orifice Tube/Expansion Valve: A partially clogged orifice tube or a malfunctioning expansion valve can restrict refrigerant flow, leading to inefficient cooling and uneven temperature distribution within the system. This can contribute to increased heat soak and poor overall performance. Inspect and replace if necessary.

- Inefficient Compressor: An aging or failing compressor may not be able to maintain proper refrigerant pressure and circulation, reducing the system's overall cooling capacity. This can make the heat soak effect more pronounced. Perform a compression test on the compressor.

- Poor Insulation: Deteriorated or missing insulation on refrigerant lines can allow them to absorb more heat from the engine bay, further contributing to the heat soak effect. Replace damaged insulation.

- Overcharged Refrigerant: While less common, an overcharged system can also cause issues. Too much refrigerant can lead to excessive pressure and reduced cooling capacity. Always adhere to the manufacturer's specifications for refrigerant charge.

Do's and Don'ts / Best Practices

- Do: Regularly inspect and clean the condenser fins.

- Do: Check and maintain the correct refrigerant charge level.

- Do: Ensure the condenser fan is functioning properly.

- Do: Consider adding aftermarket heat shielding to refrigerant lines in high-heat areas.

- Do: Have your A/C system professionally serviced periodically for leak checks and performance evaluation.

- Don't: Overcharge the system with refrigerant.

- Don't: Mix different types of refrigerant.

- Don't: Ignore unusual noises or smells coming from the A/C system.

- Don't: Attempt to repair the A/C system without proper training and tools. Refrigerant handling requires specialized equipment and knowledge due to environmental regulations and safety concerns.

Conclusion

The phenomenon of hot air blowing from your A/C after shutting off the engine is primarily due to heat soak. While it's often a normal occurrence, addressing underlying issues such as low refrigerant, clogged condenser fins, or a faulty condenser fan can significantly minimize the effect and improve overall A/C performance. If you're comfortable performing basic maintenance, you can tackle some of these issues yourself. However, for more complex repairs involving refrigerant handling, it's always best to consult a qualified automotive technician. By understanding the inner workings of your car's A/C system, you can ensure a more comfortable and efficient driving experience, especially during those scorching summer months. Remember, preventative maintenance is key to keeping your A/C system running smoothly and avoiding costly repairs down the road. If you notice a significant increase in the duration or intensity of the hot air blast, it's a clear sign that something is amiss and warrants further investigation by a professional.