When Did 4 Wheel Drive Come Out

The advent of four-wheel drive (4WD), sometimes also referred to as all-wheel drive (AWD), represents a pivotal moment in automotive history. Understanding its origins, technical evolution, and practical considerations is crucial for any serious car enthusiast, modder, or DIY mechanic. This article delves into the history of 4WD, tracing its development from its earliest conceptions to its modern, sophisticated forms, while also addressing maintenance concerns and best practices for its upkeep.

Early Concepts and Implementations

The desire to improve traction and off-road capability predates the internal combustion engine. However, the practical application of 4WD emerged alongside the development of reliable gasoline engines. While pinning down an exact "birthdate" is tricky due to varying definitions and experimental prototypes, we can identify key milestones.

One of the earliest documented examples is the Spyker 60 HP, built in 1903 by the Dutch brothers Jacobus and Hendrik-Jan Spijker (later Anglicized to Spyker). Designed for off-road travel, it featured a four-wheel-drive system and a four-wheel braking system – revolutionary for its time. While technically 4WD, the Spyker's system was complex and relatively unreliable by modern standards. It lacked the refined engineering and durability we expect today.

Around the same time, several other inventors and engineers were experimenting with similar concepts. The early applications were primarily geared toward military and agricultural vehicles, highlighting the practical need for enhanced traction in challenging terrains. For example, designs from the Austrian engineer Ferdinand Porsche were also explored in the early 1900s, again primarily for military applications. These designs further refined the concept, but mass production and widespread adoption were still some years away.

The Rise of Practical 4WD Systems

The First World War provided significant impetus for the development and refinement of 4WD technology. Military vehicles needed to traverse muddy battlefields and navigate difficult terrain. This demand led to the development of more robust and reliable systems. The Jeffery Quad, produced from 1913 onwards, became a prominent example of early military 4WD. It was a heavy-duty truck used extensively by the US Army. Its success demonstrated the viability of 4WD in demanding real-world conditions.

Following WWI, the technology continued to evolve. The Marmon-Herrington Company, founded in 1931, played a crucial role in popularizing 4WD in commercial vehicles. They focused on converting standard Ford trucks to 4WD, making the technology more accessible to a wider range of users, including farmers, construction workers, and utility companies.

Technical Breakdown: How 4WD Works

To understand 4WD, it's essential to grasp the concept of torque distribution. In a standard two-wheel-drive vehicle, the engine's power is delivered to only two wheels. In slippery conditions, this can easily lead to wheel spin, where one wheel loses traction and the vehicle gets stuck.

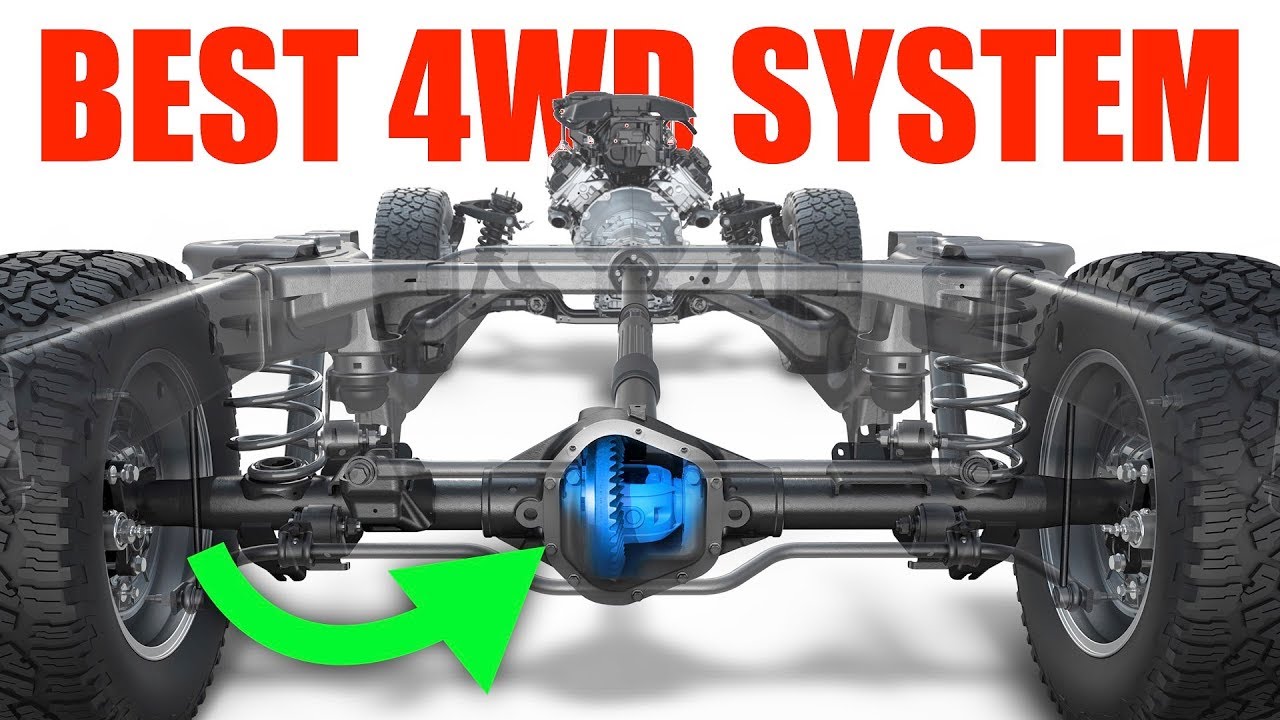

4WD systems address this by distributing torque to all four wheels. The transfer case is a critical component in a 4WD system. It sits behind the transmission and splits the engine's power between the front and rear axles. Older systems often used a manual transfer case, requiring the driver to engage 4WD by shifting a lever. Newer systems often utilize electronic shift-on-the-fly mechanisms, allowing the driver to switch between 2WD and 4WD while the vehicle is in motion (within certain speed limits).

There are different types of 4WD systems. A simple part-time 4WD system locks the front and rear axles together, forcing them to rotate at the same speed. This provides maximum traction but is only suitable for low-traction surfaces like dirt or snow. Using part-time 4WD on dry pavement can cause driveline bind, leading to damage to the transfer case and axles.

All-Wheel Drive (AWD) systems, often found in cars and SUVs, typically use a center differential or viscous coupling to distribute torque between the front and rear axles. This allows for more sophisticated torque management and can be used on pavement without the risk of driveline bind. Some AWD systems are reactive, sending power to the axle with the most traction when wheel slip is detected. Others are proactive, constantly adjusting torque distribution based on sensor data.

Common Issues and Maintenance Concerns

Like any complex mechanical system, 4WD systems are prone to certain issues. Regular maintenance is crucial to ensure their longevity and reliability.

- Transfer Case Issues: Leaks, noises (grinding, whining), and difficulty shifting are common problems. These can be caused by worn seals, low fluid levels, or damaged gears. Regular fluid changes are essential.

- Axle Issues: Worn axle shafts, U-joints, and CV joints can lead to vibrations, clunking noises, and ultimately, failure. Inspect these components regularly for wear and tear.

- Differential Issues: Similar to the transfer case, differentials can suffer from leaks, noises, and worn gears. Proper lubrication is critical.

- Driveline Bind: As mentioned earlier, using part-time 4WD on dry pavement can cause driveline bind. This puts excessive stress on the transfer case and axles, potentially leading to damage.

It's important to use the correct type of fluid in the transfer case and differentials. Consult your vehicle's owner's manual for the recommended specifications. Using the wrong fluid can lead to premature wear and failure.

Do's and Don'ts / Best Practices

Proper usage and maintenance are crucial for keeping your 4WD system in top condition.

- Do: Regularly inspect your 4WD system for leaks, noises, and worn components.

- Do: Change the fluid in the transfer case and differentials according to the manufacturer's recommendations.

- Do: Use the correct type of fluid specified in your owner's manual.

- Do: Familiarize yourself with the different 4WD modes available on your vehicle and use them appropriately.

- Don't: Use part-time 4WD on dry pavement.

- Don't: Ignore unusual noises or vibrations coming from the driveline.

- Don't: Overload your vehicle beyond its rated capacity.

- Don't: Neglect basic maintenance, such as lubrication and visual inspections.

If you're considering modifying your 4WD system, such as installing a lift kit or larger tires, be sure to research the potential impacts on other components, such as the axles and suspension. Improperly installed modifications can lead to premature wear and even failure.

Conclusion

The history of 4WD is a testament to human ingenuity and the constant pursuit of improved traction and off-road capability. From its early, experimental beginnings in the early 1900s to its modern, sophisticated forms, 4WD has revolutionized the way we travel and work in challenging environments. By understanding the technical aspects of 4WD systems, performing regular maintenance, and following best practices, you can ensure that your 4WD vehicle remains a reliable and capable machine for years to come.

Recommendation: For intermediate car owners and DIY mechanics, understanding the fundamentals of 4WD, coupled with a proactive approach to maintenance and repair, is crucial. Invest in a good quality service manual specific to your vehicle. Regularly inspect the system and address any issues promptly. This will save you time, money, and potential headaches down the road.