When Did Cvt Transmission Come Out

The quest for smoother, more efficient power delivery in automobiles has been a long and winding road, dotted with various transmission technologies. Among them, the Continuously Variable Transmission, or CVT, stands out as a design promising seamless gear ratio changes. But when did this innovative technology first make its appearance, and how has it evolved over time?

Pinpointing the "birth" of the CVT isn't straightforward. The core principle of continuously variable ratios predates the automobile itself. Think of a manually-operated winch; by adjusting the length of the handle, you continuously change the mechanical advantage, effectively creating an infinite number of "gear ratios." Applying this concept to vehicular propulsion, however, proved to be a substantial engineering challenge.

Early Beginnings: A Century of Development

The earliest conceptualization of a CVT-like device can be traced back to 1886, when Karl Benz, the father of the modern automobile, patented a rudimentary cone pulley CVT for his Patent-Motorwagen. However, this design was never practically implemented in a production vehicle. Several other early attempts followed in the late 19th and early 20th centuries, primarily focusing on cone and roller-based systems.

To illustrate the concept, imagine two cones placed point-to-point, with a belt or wheel running between them. By moving the belt along the cones' surfaces, you can alter the effective diameter ratio, thus varying the output speed relative to the input speed. These early CVTs, while conceptually sound, suffered from limitations in power transfer capability, durability, and control.

A significant milestone occurred in 1958 when DAF, a Dutch automaker, introduced the Daffodil. This compact car featured the Variomatic transmission, a rubber belt-based CVT. The Variomatic used two variable-diameter pulleys connected by rubber belts. This was the first truly successful, mass-produced application of a CVT in an automobile. However, the Variomatic's power handling was limited by the strength of the rubber belts.

The Modern CVT: Steel Belts and Electronic Control

The modern CVT, as we know it today, largely owes its development to improvements in materials science and electronic control systems. The crucial innovation was the replacement of rubber belts with metal pushbelts or chains. These belts, constructed from interlocking steel elements, are capable of transmitting significantly higher torque and offer improved durability. This advancement paved the way for CVTs to be used in larger, more powerful vehicles.

How it Works: A Deeper Dive

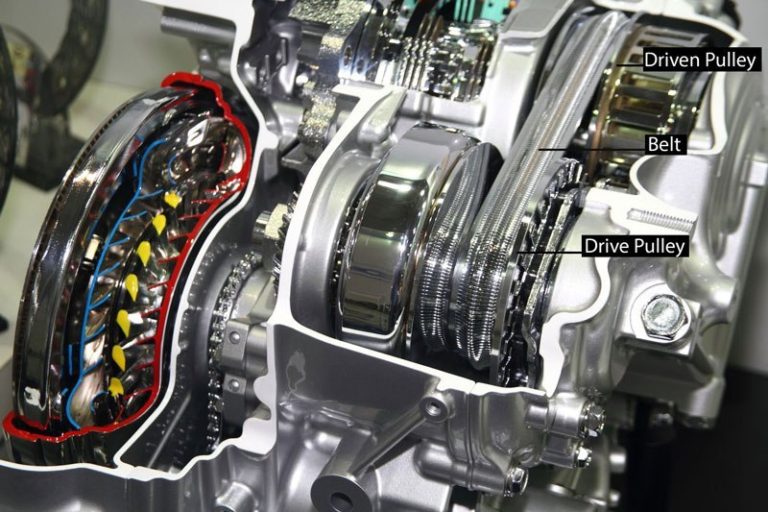

At its heart, a CVT consists of two variable-diameter pulleys, each composed of two conical discs. A belt or chain runs between these pulleys. One pulley is connected to the engine's crankshaft (the input), and the other is connected to the vehicle's driveshaft (the output). Hydraulic pressure controls the distance between the conical discs in each pulley. When the discs are close together, the effective diameter of the pulley is large; when they are far apart, the diameter is small. By coordinating the changes in diameter of both pulleys, the CVT can achieve a continuous range of gear ratios.

Think of it like riding a bicycle with continuously adjustable sprockets. You could infinitely fine-tune the effort required to pedal based on the terrain and your desired speed. In a CVT, the electronic control unit (ECU) constantly monitors various parameters, such as engine speed, vehicle speed, throttle position, and load, to determine the optimal gear ratio. Hydraulic actuators then adjust the pulley diameters accordingly, providing seamless and efficient power delivery.

Modern CVTs also often incorporate a torque converter, similar to those found in traditional automatic transmissions. The torque converter acts as a fluid coupling, allowing the engine to idle without stalling and providing torque multiplication at low speeds. Some CVTs also feature simulated "steps" or fixed gear ratios to mimic the feel of a conventional automatic transmission, addressing driver concerns about the "rubber band" effect (a sensation of the engine revving up without a corresponding increase in vehicle speed).

Pros and Cons of CVT Technology

Pros:

- Fuel Efficiency: CVTs can keep the engine operating at its most efficient speed (RPM) for any given driving condition, resulting in better fuel economy compared to traditional automatic transmissions.

- Smoothness: The seamless gear ratio changes provide a very smooth and comfortable driving experience.

- Performance: CVTs can offer quicker acceleration in certain situations by keeping the engine in its peak power band.

- Simplicity: In some ways, the mechanical design of a CVT is simpler than a complex multi-gear automatic transmission.

Cons:

- "Rubber Band" Effect: As mentioned earlier, the lack of distinct gear changes can feel unnatural to some drivers, leading to a perception of sluggishness.

- Noise: Some CVTs can produce a noticeable drone or whine, especially during acceleration.

- Durability Concerns: Early CVTs, and even some modern ones, have faced concerns regarding long-term durability, especially under high-stress conditions.

- Driving Feel: Despite advancements, some drivers still dislike the disconnected feeling compared to traditional automatics or manuals.

- Maintenance: Requires specialized fluid changes that are different than traditional automatics.

Use Cases and Manufacturer Examples

CVTs are commonly found in a wide range of vehicles, from compact cars and sedans to crossovers and even some SUVs. They are particularly well-suited for vehicles where fuel efficiency is a primary concern. Several major automakers have embraced CVT technology.

- Nissan: Nissan is one of the most prolific users of CVTs, employing them in models like the Altima, Rogue, Sentra, and Versa.

- Honda: Honda uses CVTs in models like the Civic, Accord, and CR-V.

- Subaru: Subaru equips many of its vehicles, including the Impreza, Crosstrek, and Outback, with CVTs.

- Toyota: Toyota utilizes CVTs in models like the Corolla and Prius.

Interestingly, even high-performance vehicles are exploring CVT technology. Some manufacturers are experimenting with CVTs coupled with electric motors in hybrid and electric vehicles, leveraging the CVT's ability to keep the electric motor operating at its most efficient RPM range.

Real-World Insights and Recommendations

The CVT has come a long way since its humble beginnings. Modern CVTs offer significantly improved performance, durability, and refinement compared to earlier iterations. However, it's essential to understand the technology's strengths and weaknesses before making a purchase decision.

If fuel efficiency and a smooth driving experience are your priorities, a vehicle equipped with a well-engineered CVT can be an excellent choice. However, if you prefer the more engaging feel of a traditional automatic transmission with distinct gear changes, you may find the CVT's characteristics less appealing.

Before buying a car with a CVT:

- Test drive the vehicle thoroughly: Pay close attention to the CVT's behavior during acceleration, deceleration, and cruising.

- Research reliability ratings: Check consumer reports and online forums for information on the CVT's long-term reliability.

- Inquire about maintenance requirements: Understand the CVT fluid change intervals and the cost of these services.

In conclusion, the CVT represents a significant advancement in transmission technology. While it may not be the perfect solution for every driver, its ability to deliver seamless power and improved fuel efficiency makes it a compelling option in today's automotive landscape. The "when" of the CVT is not a single point in time, but rather a continuous journey of innovation and refinement, starting with early concepts and culminating in the sophisticated systems we see on the road today. The future of CVT technology likely lies in further integration with hybrid and electric powertrains, as well as continued improvements in durability and driver engagement.