When Did The 6.7 Cummins Come Out

Okay, so you're wondering about the 6.7 Cummins, specifically, when it came out. Maybe you're having some issues, trying to diagnose something, or just plain curious. Understanding the history of this engine can be a big help in figuring out what you're dealing with, especially when it comes to potential problems. So, let's dive in.

The Question: When Did the 6.7 Cummins Debut?

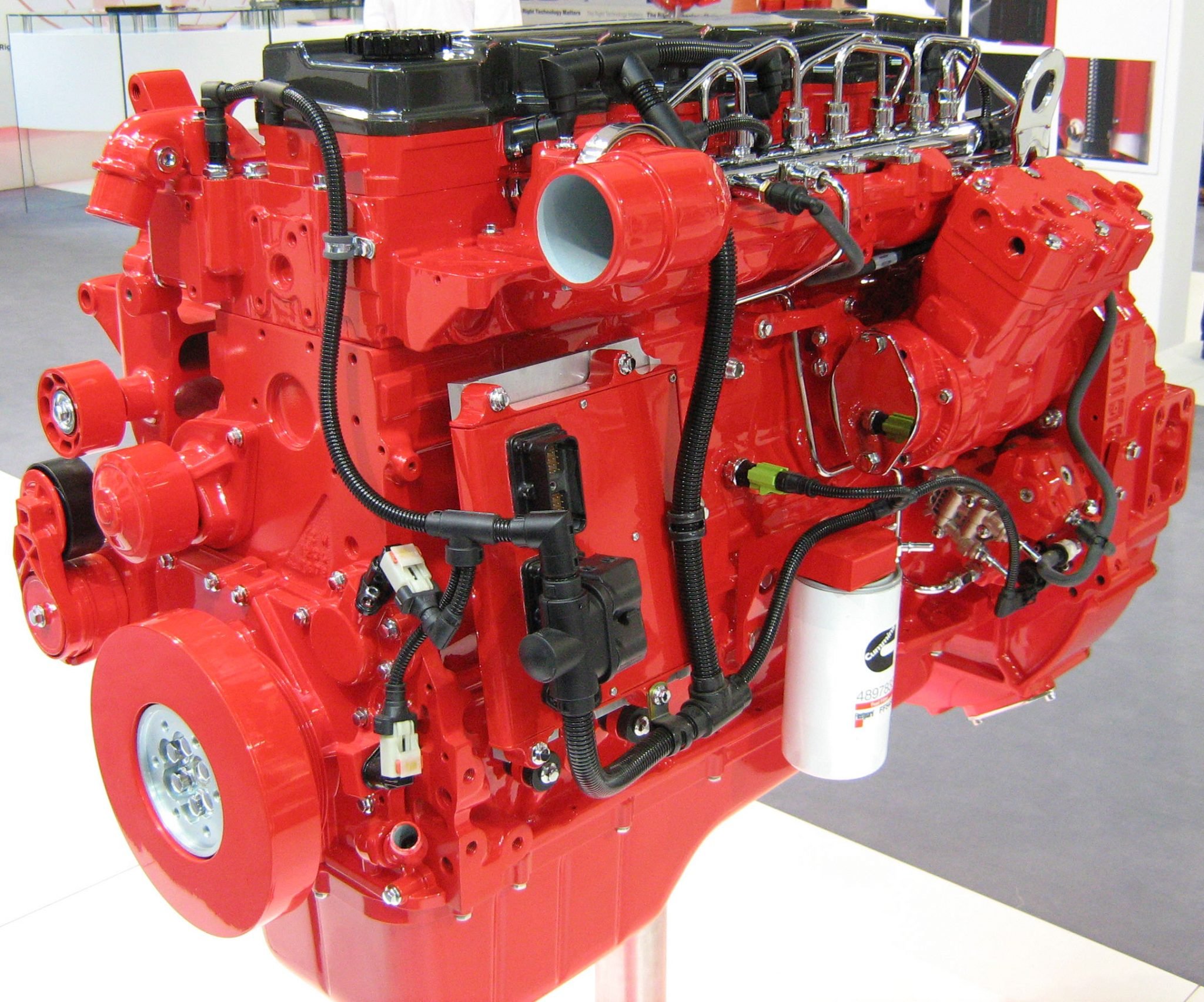

The 6.7-liter Cummins turbodiesel engine was first introduced in 2007 Dodge Ram (now Ram) trucks as a replacement for the 5.9-liter Cummins. That's the short answer. But understanding why it was introduced, and the changes that came along with it, is what’s really important for diagnosing and maintaining your truck.

Why is this important to know? Because 2007 wasn't just a simple engine swap. It marked a significant shift in emissions regulations and technology for diesel trucks. Knowing this helps you understand which specific components and potential issues might apply to your truck, based on its model year. A 2007 truck has different considerations than a 2012, for example, even though they both have a 6.7 Cummins.

Common Symptoms Suggesting 6.7 Cummins Issues

Before getting deeper into the technical details, let's cover some common symptoms that might lead you to research the 6.7 Cummins:

- Decreased Fuel Economy: A sudden or gradual drop in MPG can indicate various problems, from injector issues to turbocharger inefficiencies.

- Excessive Black Smoke: This often points to incomplete combustion, possibly due to faulty injectors, an air intake problem, or a malfunctioning EGR (Exhaust Gas Recirculation) system.

- Check Engine Light (CEL): A CEL is a broad indicator, but it almost always means something needs attention. Getting the code read is the first step.

- Rough Idle: An unstable or shaky idle can be caused by injector problems, a failing fuel pump, or even a clogged fuel filter.

- Loss of Power: A noticeable decrease in acceleration or the ability to tow can signal turbocharger issues, fuel delivery problems, or exhaust restrictions.

- Turbocharger Whine or Noise: Unusual noises from the turbocharger area can suggest bearing wear or damage.

- Engine Knocking or Tapping: While diesel engines are naturally noisy, unusual knocking or tapping sounds can indicate serious problems like rod knock or piston slap.

- Coolant Loss: Especially if accompanied by white smoke from the exhaust, this could mean a head gasket issue, a common problem on some 6.7 Cummins models, or issues with the EGR cooler.

- Oil Consumption: Increased oil consumption can indicate worn piston rings, valve stem seals, or a turbocharger leak.

Root Cause Analysis: Diving Deep into the 6.7 Cummins

The 6.7 Cummins was introduced primarily to meet stricter EPA emissions regulations. This led to significant design changes compared to the 5.9-liter engine. Here's a breakdown of some key differences and their implications:

- Increased Displacement: The bore was increased to achieve 6.7 liters, resulting in more torque and power, but also potentially higher heat generation.

- Exhaust Gas Recirculation (EGR): EGR systems recirculate exhaust gases back into the intake manifold to reduce NOx emissions. However, EGR systems are prone to clogging with soot and carbon buildup, which can lead to performance issues and increased maintenance.

- Diesel Particulate Filter (DPF): The DPF traps soot and particulate matter from the exhaust. Regular regeneration cycles are required to burn off the accumulated soot. If the DPF becomes clogged, it can cause reduced power, poor fuel economy, and even engine damage. Short trips where the engine doesn't reach operating temperature are particularly hard on the DPF.

- Variable Geometry Turbocharger (VGT): The VGT allows the turbocharger to adjust its output based on engine load and speed, improving responsiveness and efficiency. However, the VGT mechanism can become clogged with soot and carbon buildup, leading to performance issues.

- High-Pressure Common Rail (HPCR) Fuel System: The HPCR system delivers fuel at extremely high pressures for improved combustion efficiency and reduced emissions. However, the HPCR system is very sensitive to fuel contamination. Dirty or contaminated fuel can damage injectors and the high-pressure fuel pump.

Ignoring the Problem: Potential Consequences

Ignoring these symptoms can lead to serious and costly consequences. A small problem, like a slightly clogged EGR valve, can quickly escalate into a major repair, such as a complete engine failure. Here's a breakdown of what can happen if you ignore common 6.7 Cummins issues:

- DPF Failure: A clogged DPF can cause backpressure, leading to engine damage and potentially requiring replacement of the DPF, a very expensive repair.

- Turbocharger Damage: Ignoring a failing turbocharger can lead to catastrophic failure, sending debris into the engine and causing significant damage.

- Injector Failure: Dirty or contaminated fuel can cause injectors to fail, leading to poor fuel economy, rough idle, and even engine damage. Replacing injectors can be a costly repair.

- EGR System Failure: A clogged EGR system can cause reduced power, poor fuel economy, and increased emissions. Ignoring the issue can lead to engine damage.

- Engine Damage: Ignoring engine knocking or tapping sounds can lead to serious engine damage, potentially requiring a complete engine rebuild or replacement. Overheating due to coolant loss can also cause major engine damage.

- Reduced Resale Value: A poorly maintained truck will have a significantly lower resale value.

Recommended Fixes for Common 6.7 Cummins Problems

The appropriate fix depends entirely on the symptom and root cause. Here are some common solutions:

- Fuel System Cleaning: Regularly using a fuel system cleaner can help prevent injector problems.

- Fuel Filter Replacement: Replacing the fuel filter at the recommended intervals is crucial to prevent fuel contamination.

- Air Filter Replacement: A clean air filter ensures proper airflow to the engine.

- EGR Valve Cleaning or Replacement: Cleaning or replacing the EGR valve can restore proper EGR system function.

- DPF Regeneration: Performing a manual DPF regeneration can help clear a clogged DPF. In some cases, a professional DPF cleaning or replacement may be necessary.

- Turbocharger Repair or Replacement: Repairing or replacing a failing turbocharger can restore proper engine performance.

- Injector Replacement: Replacing faulty injectors can restore proper fuel delivery and engine performance.

- Coolant System Inspection and Repair: Inspecting and repairing the coolant system can prevent overheating and engine damage.

- Oil Change with High-Quality Oil: Using high-quality oil and changing it at the recommended intervals can help prevent engine wear and tear.

Cost Estimates and Shop Advice

Repair costs can vary significantly depending on the specific problem, the shop you choose, and the parts used. Here's a general idea:

- Fuel Injector Replacement: $400 - $800 per injector (parts and labor).

- Turbocharger Replacement: $1500 - $3500 (parts and labor).

- DPF Replacement: $2000 - $4000 (parts and labor).

- EGR Valve Replacement: $300 - $800 (parts and labor).

Shop Advice: Always get a second opinion, especially for major repairs. Make sure the shop is experienced with diesel engines and specifically, the 6.7 Cummins. Ask about their diagnostic process and what kind of warranty they offer on their work. Don't be afraid to ask questions!

Credibility: TSBs, Community Data, and Mileage for Failure

Several factors support the information presented here. For example:

- TSBs (Technical Service Bulletins): Cummins and Ram issue TSBs to address common problems and provide repair procedures. Checking TSBs related to your specific model year can provide valuable insights. For example, there are TSBs related to EGR cooler failures, injector issues, and turbocharger problems.

- Community Data: Online forums and owner communities are a wealth of information. Owners often share their experiences, including common problems, repair costs, and maintenance tips. These communities can provide real-world data and help you understand what to expect.

- Common Mileage for Failure: While it varies depending on maintenance and usage, certain components tend to fail around specific mileage ranges. For example, EGR coolers often fail between 100,000 and 150,000 miles. Injectors can start to fail around 150,000 to 200,000 miles. Knowing these common failure points can help you plan for preventative maintenance.

Understanding when the 6.7 Cummins came out and the changes that came with it is crucial for diagnosing and addressing potential problems. By being proactive and addressing symptoms early, you can prevent costly repairs and keep your truck running smoothly for years to come.