When Do Nissan Cvt Transmissions Fail

The dreaded words: CVT failure. For Nissan owners, particularly those with vehicles from the mid-2000s onward, this phrase can evoke a sense of anxiety. Continuously Variable Transmissions (CVTs) promised improved fuel economy and smoother driving, but their reliability, especially in certain Nissan models, has been a persistent concern. This article aims to delve into the reasons behind CVT failures in Nissan vehicles, providing a technical understanding of the system, common issues, and preventative measures you can take to prolong its life.

Background: The Nissan CVT and Its Applications

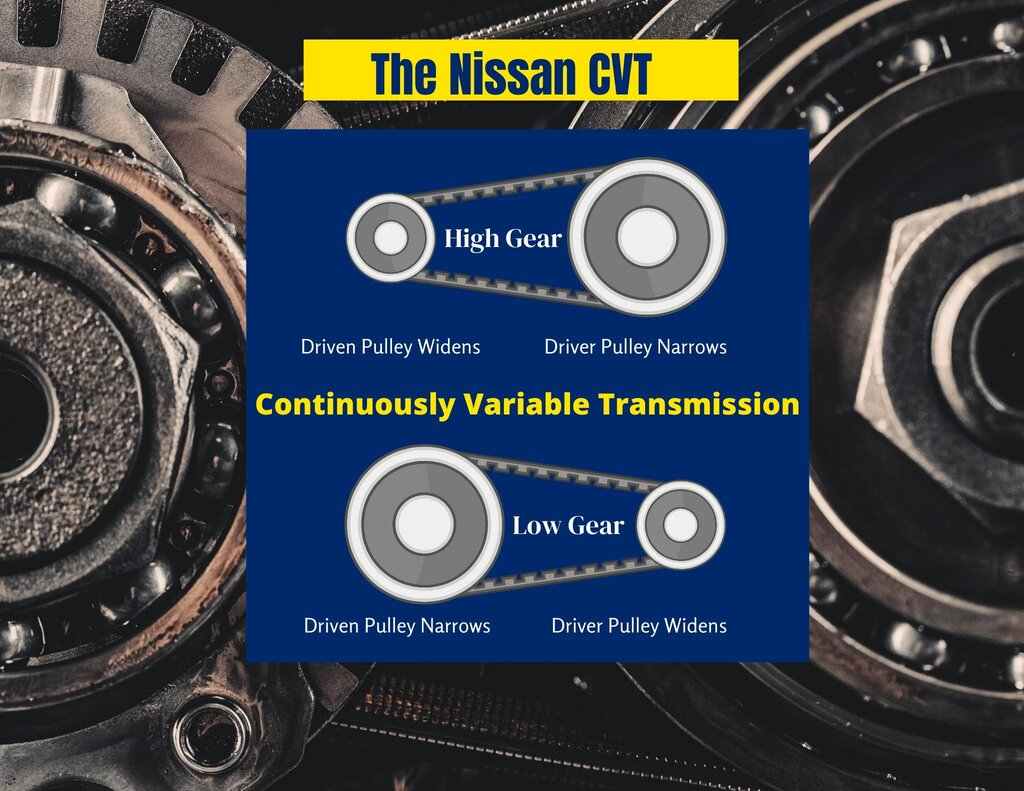

Nissan has been a prominent adopter of CVT technology, integrating it into a wide range of models, including the Altima, Sentra, Rogue, Murano, and Pathfinder. The appeal of the CVT lies in its ability to provide a theoretically infinite number of gear ratios. Unlike traditional automatic transmissions that rely on fixed gear sets, the CVT uses a belt or chain running between two variable-diameter pulleys. This allows for seamless transitions and keeps the engine operating at its most efficient RPM range, boosting fuel economy and reducing emissions. However, the long-term durability of these CVTs has been a subject of debate.

Technical Breakdown: How a CVT Works

To understand why Nissan CVTs fail, it's essential to grasp their fundamental operation. The core of the system consists of:

- Input Pulley (Primary Pulley): Connected to the engine, this pulley's diameter changes in response to engine speed and driver input.

- Output Pulley (Secondary Pulley): This pulley is connected to the driveshaft and also adjusts its diameter inversely to the input pulley.

- Belt or Chain: A high-strength belt (typically made of steel) or chain transmits power between the pulleys. The strength and design of this belt are critical.

- Hydraulic Control System: A sophisticated hydraulic system, controlled by the transmission control module (TCM), manages the pulley diameters based on sensor data. This system also controls the clutch packs that engage reverse.

- Transmission Control Module (TCM): The TCM is the brain of the CVT. It receives information from various sensors (engine speed, vehicle speed, throttle position, etc.) and calculates the optimal pulley ratios for desired performance and efficiency.

- CVT Fluid: Specialized fluid is crucial for lubrication, cooling, and transmitting hydraulic pressure to the pulleys. The fluid's properties are specifically designed for the CVT's unique demands.

The TCM uses algorithms to determine the ideal pulley ratio based on driving conditions. For example, during acceleration, the input pulley diameter decreases while the output pulley diameter increases, effectively creating a low gear ratio for increased torque. During cruising, the opposite occurs, creating a higher gear ratio for fuel efficiency.

Simplified Operation:

- The engine drives the input pulley.

- The TCM analyzes driving conditions and commands the hydraulic control system to adjust the pulley diameters.

- The belt or chain transmits power from the input pulley to the output pulley.

- The output pulley drives the driveshaft, which in turn powers the wheels.

Common Issues and Maintenance Concerns Leading to Failure

Several factors contribute to CVT failures in Nissan vehicles:

- Fluid Degradation and Contamination: This is perhaps the most common culprit. CVT fluid is highly specialized and susceptible to degradation due to heat, friction, and oxidation. Over time, the fluid loses its lubricating properties, leading to increased wear and tear on the pulleys, belt, and other internal components. Contamination from wear particles further exacerbates the problem. Nissan's recommended fluid change intervals, often considered too long by experienced mechanics, can accelerate this process.

- Overheating: CVTs generate significant heat, particularly under heavy load (towing, hill climbing, aggressive driving). Insufficient cooling can lead to fluid breakdown, component damage, and ultimately, failure. Many Nissan vehicles with CVTs lack adequate transmission coolers, especially in hotter climates.

- Belt/Chain Slippage: Under high torque loads or due to worn pulleys, the belt or chain can slip. This slippage generates excessive heat and friction, damaging the belt/chain and the pulley surfaces. Repeated slippage can lead to catastrophic failure.

- Hydraulic System Malfunctions: Issues with the hydraulic control system, such as faulty solenoids, clogged valves, or internal leaks, can prevent the pulleys from adjusting correctly. This can result in erratic shifting, reduced performance, and increased wear.

- TCM Problems: Although less common, failures within the TCM can disrupt the CVT's operation, leading to incorrect pulley ratios, erratic behavior, and eventually, damage.

- Lack of Maintenance: Neglecting regular fluid changes and inspections drastically shortens the CVT's lifespan. Many owners only discover the importance of CVT maintenance after experiencing problems.

- Aggressive Driving: Hard acceleration, frequent stop-and-go traffic, and towing beyond the vehicle's capacity put excessive strain on the CVT, accelerating wear and tear.

Symptoms of a failing CVT often include:

- Jerky or erratic acceleration.

- Hesitation or delays in engagement.

- Unusual noises (whining, buzzing, or clunking).

- Vibration or shaking.

- Difficulty maintaining speed.

- Warning lights (e.g., transmission warning light).

- Limp mode (reduced power and speed).

Do's and Don'ts / Best Practices for CVT Longevity

Extending the life of your Nissan CVT requires proactive maintenance and mindful driving habits:

Do's:

- Change the CVT fluid regularly: Shorten the factory-recommended interval. Many mechanics recommend changing the fluid every 30,000 miles, especially if you engage in frequent highway driving, towing, or live in a hot climate. Use only the specified Nissan CVT fluid (usually NS-2, NS-3, or NS-4 depending on the model and year). Using the wrong fluid can cause immediate and severe damage.

- Consider installing an auxiliary transmission cooler: This is particularly beneficial if you tow or live in a hot climate. An aftermarket cooler can significantly reduce CVT operating temperatures.

- Monitor CVT temperature: If possible, use a scan tool or app to monitor the CVT temperature. Keeping the temperature within the safe operating range (typically below 220°F or 104°C) can help prevent fluid degradation.

- Perform regular inspections: Check for leaks around the transmission and inspect the fluid for signs of contamination (dark color, burnt smell).

- Drive conservatively: Avoid hard acceleration, aggressive driving, and towing beyond the vehicle's rated capacity.

- Allow the CVT to warm up: In cold weather, allow the engine and CVT to warm up for a few minutes before driving.

- Consult a qualified mechanic: If you notice any symptoms of CVT problems, take your vehicle to a qualified mechanic for diagnosis and repair.

Don'ts:

- Ignore warning signs: Addressing CVT problems early can prevent more serious and costly damage.

- Use the wrong CVT fluid: Using non-specified fluid is a surefire way to destroy your CVT.

- Overfill or underfill the CVT fluid: Maintaining the correct fluid level is crucial. Use a dipstick (if equipped) or follow the manufacturer's instructions carefully.

- Neglect maintenance: Regular fluid changes are essential for CVT longevity.

- Tow beyond the vehicle's capacity: Towing heavy loads puts excessive strain on the CVT.

- Assume a "lifetime" fluid claim is true: There's no such thing as lifetime fluid. It will degrade over time, leading to problems.

Conclusion: Proactive Care for CVT Longevity

While Nissan CVTs have faced reliability challenges, particularly in earlier models, proactive maintenance and mindful driving habits can significantly extend their lifespan. The key is to prioritize regular fluid changes using the correct fluid, avoid aggressive driving, and address any symptoms of problems promptly. By understanding the technical aspects of the CVT and following best practices, you can minimize the risk of failure and enjoy the benefits of this technology for years to come. If you're unsure about performing CVT maintenance yourself, consult a trusted mechanic who specializes in these transmissions. A little preventative care can save you from a potentially expensive and frustrating CVT failure.