When Does The Vc-turbo Engine Use Higher Compression Ratios

Variable compression engines, like Nissan's VC-Turbo, represent a fascinating leap in internal combustion engine technology. As experienced DIYers or budding mechanics, you've likely heard the buzz around these engines and their ability to dynamically adjust their compression ratio on the fly. But understanding when and why they use higher compression ratios is key to truly appreciating the engineering and potential benefits (and potential pitfalls) of these complex systems. This article dives deep into the VC-Turbo engine, explaining when it utilizes higher compression, the technical reasons behind these decisions, and offering insights into maintenance and best practices.

A Brief History of the VC-Turbo Engine

The idea of a variable compression engine isn't new. Engineers have been toying with the concept for decades, aiming to combine the fuel efficiency benefits of high compression ratios with the power and responsiveness associated with lower ratios. The challenge was creating a reliable and durable system that could handle the stresses of continuous adjustment. Nissan's VC-Turbo engine, after years of development, represents a commercially viable solution. It achieves variable compression by using a multi-link system connected to the connecting rod, effectively changing the piston's reach within the cylinder.

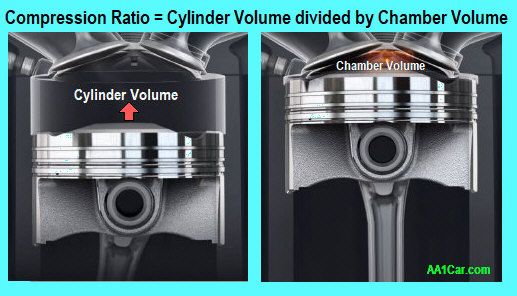

Traditional engines have a fixed compression ratio, which is the ratio of the cylinder volume when the piston is at the bottom of its stroke (Bottom Dead Center or BDC) to the cylinder volume when the piston is at the top of its stroke (Top Dead Center or TDC). Higher compression ratios generally improve thermal efficiency, meaning the engine extracts more energy from the fuel, leading to better fuel economy. However, excessively high compression can lead to knocking (pre-ignition) and increased stress on engine components. Lower compression ratios, on the other hand, are generally used for performance applications, as they allow for more boost from turbochargers and reduce the likelihood of knocking, but at the cost of fuel efficiency.

Technical Breakdown: When and Why Higher Compression is Used

The VC-Turbo engine strategically adjusts its compression ratio based on several factors, primarily engine load, throttle position, and RPM. Let's break down the scenarios where higher compression ratios are favored:

1. Light Load and Cruising Conditions

This is arguably the most common scenario where the VC-Turbo utilizes its highest compression ratio. During steady-state cruising at highway speeds or light city driving, the engine is under minimal load. In these conditions, the engine control unit (ECU) commands the actuator motor to adjust the multi-link system, increasing the compression ratio to its maximum value (typically around 14:1). This higher compression promotes more complete combustion of the air-fuel mixture, maximizing fuel efficiency and reducing emissions. Think of it as squeezing every last drop of energy from the fuel.

2. Low to Mid-Range RPMs

At lower and mid-range engine speeds (e.g., 1500-3000 RPM), the engine generally benefits from higher compression. The longer combustion duration at these speeds allows the higher compression ratio to be effectively utilized for improved thermal efficiency. The ECU monitors RPM and adjusts the compression accordingly. You might notice this transition if you're gently accelerating from a stop or maintaining a steady speed on a flat road. The engine feels responsive and efficient, but without the aggressive power delivery associated with a lower compression, boosted scenario.

3. Part-Throttle Applications

Even when not at full throttle, the VC-Turbo can still benefit from a higher compression ratio. During part-throttle acceleration or when maintaining speed uphill, the ECU can increase the compression ratio to improve engine response and fuel economy. This allows the engine to provide adequate power without needing to resort to full boost, which would consume more fuel. The ECU uses sophisticated algorithms to determine the optimal compression ratio based on throttle position, engine speed, and other sensor inputs.

4. Cold Start (With Limitations)

While not a sustained high-compression scenario, the VC-Turbo may briefly utilize a slightly higher compression ratio during a cold start to aid in combustion. However, this is limited. Extremely high compression during a cold start can make the engine difficult to crank and put excessive strain on the starter motor. Therefore, the ECU manages the compression carefully during this phase, balancing the need for improved combustion with the need to protect engine components. The system monitors coolant temperature and adjusts compression accordingly, favoring a slightly higher ratio as the engine warms up.

Important Note: The exact compression ratio used in each scenario is determined by a complex set of parameters within the ECU and can vary depending on the specific vehicle model and driving conditions. The ECU constantly monitors knock sensors and other engine parameters to ensure that the engine is operating safely and efficiently.

Common Issues and Maintenance Concerns

The VC-Turbo engine, with its complex variable compression system, introduces new potential points of failure compared to traditional engines. Here are some common issues and maintenance considerations:

1. Actuator Motor Failure

The actuator motor, responsible for adjusting the multi-link system and changing the compression ratio, is a critical component. If this motor fails, the engine may be stuck at a fixed compression ratio, potentially affecting performance and fuel economy. Symptoms of a failing actuator motor can include reduced fuel economy, engine knocking, or a check engine light. Regular inspection and, if necessary, replacement of the actuator motor are crucial.

2. Multi-Link System Wear and Tear

The multi-link system itself is subject to wear and tear due to the constant movement and stresses involved. Over time, the linkages and bearings can develop play, which can affect the accuracy and responsiveness of the variable compression system. This can lead to reduced performance, increased noise, or even mechanical failure. Regular inspections and lubrication of the multi-link system are important preventative measures.

3. Oil Quality and Maintenance

Proper lubrication is paramount for the VC-Turbo engine. The variable compression system relies on clean, high-quality oil to function properly. Following the manufacturer's recommended oil change intervals and using the correct oil viscosity are essential. Neglecting oil changes can lead to sludge buildup and wear in the variable compression system, potentially causing serious damage.

4. ECU Calibration and Software Updates

The ECU plays a critical role in controlling the variable compression system. Ensuring that the ECU has the latest software updates and calibrations is important for optimal performance and reliability. These updates often address known issues and improve the efficiency and accuracy of the variable compression system. Consult with a qualified technician to ensure that your ECU is up to date.

Do's and Don'ts / Best Practices

Here's a summary of do's and don'ts to keep your VC-Turbo engine running smoothly:

Do's:

- Do follow the manufacturer's recommended maintenance schedule, especially oil changes.

- Do use the recommended oil viscosity and type.

- Do keep an eye out for any unusual noises or vibrations from the engine.

- Do address any check engine lights promptly.

- Do consult a qualified technician for any issues related to the variable compression system.

- Do consider using a fuel system cleaner periodically to help maintain optimal combustion.

Don'ts:

- Don't ignore unusual engine behavior.

- Don't use low-quality oil or filters.

- Don't attempt to modify the variable compression system without proper knowledge and expertise.

- Don't delay maintenance or repairs.

- Don't assume that all aftermarket parts are compatible with the VC-Turbo engine.

Conclusion: Understanding and Maintaining Your VC-Turbo

The VC-Turbo engine represents a significant advancement in engine technology, offering a compelling combination of fuel efficiency and performance. While the variable compression system adds complexity, understanding when and why the engine uses higher compression ratios is crucial for appreciating its capabilities and maintaining its longevity. By following the recommended maintenance practices and addressing any issues promptly, you can ensure that your VC-Turbo engine continues to deliver optimal performance for years to come. If you're an experienced DIYer, tackling basic maintenance like oil changes is certainly within your reach. However, for anything related to the variable compression system itself, seeking the expertise of a trained technician is highly recommended. This complex system requires specialized tools and knowledge, and attempting repairs without the proper expertise could potentially lead to further damage and costly repairs. Embrace the technology, but respect its complexity, and your VC-Turbo will reward you with years of efficient and enjoyable driving.