1989 Lug Pattern Specifications And Hubcentric Requirements

Alright folks, let's talk about those trusty vehicles rolling around from 1989. Specifically, we're going to dive deep into the world of lug patterns and hubcentric requirements for your classic ride. This isn't always the most glamorous topic, but getting it right is crucial for safety, performance, and avoiding some serious headaches down the road. Whether you're swapping wheels, dealing with vibrations, or just want to understand your car better, this guide will help.

The Trouble with Incorrect Lug Patterns

One of the most common problems we see in the shop involves incorrect lug patterns. You might be thinking, "Well, a lug pattern is a lug pattern, right?" Wrong! The lug pattern refers to the diameter of the circle formed by the lug nuts or bolts on your wheel hub. It's usually expressed as two numbers: the number of lugs and the diameter of that circle in millimeters (mm) or inches. For example, 5x114.3mm means 5 lugs on a circle with a diameter of 114.3mm (which is also equivalent to 5x4.5 inches). Getting this wrong can lead to a whole host of issues:

- Wheel Wobble: This is perhaps the most noticeable symptom. If the lug pattern doesn't match, the wheel won't sit flush against the hub, causing it to vibrate, especially at higher speeds. This isn't just annoying; it can be downright dangerous.

- Lug Nut/Bolt Failure: When you force a wheel onto a hub with the wrong lug pattern, you're putting undue stress on the lug nuts or bolts. This can lead to them shearing off, which, as you can imagine, is not a good situation while driving.

- Damaged Wheel Bearings: The uneven load distribution from an improperly mounted wheel can prematurely wear out your wheel bearings. Replacing wheel bearings can be a fairly involved and costly repair.

- Reduced Braking Performance: Believe it or not, an improperly mounted wheel can even affect your braking performance. The vibrations and instability can make it harder to control the vehicle during braking.

So, how do you avoid this mess? First and foremost, know your lug pattern. The easiest way to find it is to consult your vehicle's owner's manual. If you don't have the manual, you can usually find this information online by searching for your car's year, make, and model along with the term "lug pattern." Alternatively, a trusted mechanic can easily identify it for you.

Tools You'll Need for Wheel Swapping

If you're planning on swapping wheels yourself (and ensuring the lug pattern is correct), here's a basic list of tools you'll need:

- Lug Wrench: A must-have for removing and tightening lug nuts. Consider investing in a quality torque wrench (see below).

- Torque Wrench: Absolutely essential for tightening lug nuts to the correct specification. Overtightening can damage the studs or warp the brake rotors, while undertightening can lead to wheel detachment.

- Jack and Jack Stands: For safely lifting and supporting the vehicle. Never work under a vehicle supported only by a jack!

- Wheel Chocks: To prevent the vehicle from rolling.

- Penetrating Oil: Helpful for loosening stubborn lug nuts.

- Wire Brush: To clean the hub surface and ensure proper wheel seating.

- Gloves: To keep your hands clean and protected.

- Safety Glasses: To protect your eyes from debris.

Hubcentric vs. Lugcentric: What's the Difference?

Now, let's move on to another crucial concept: hubcentricity. This refers to how the wheel is centered on the hub. There are two main types of wheel centering:

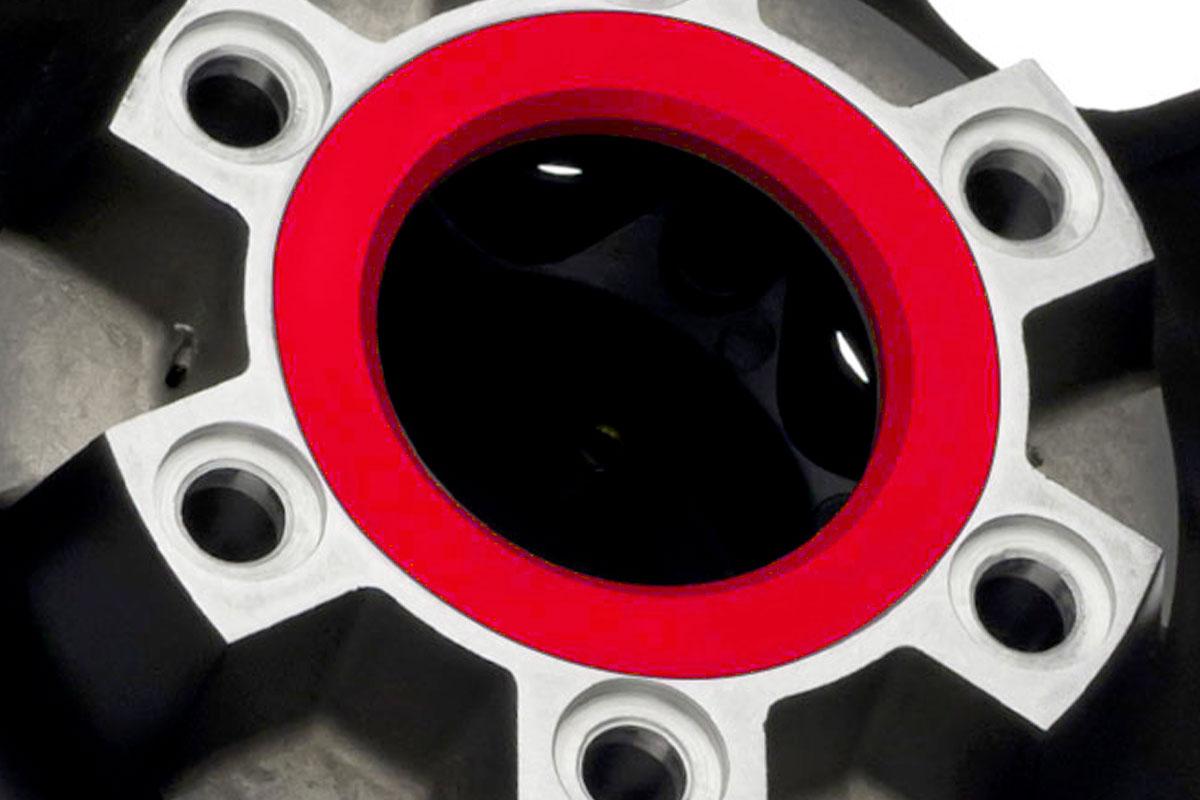

- Hubcentric: In this design, the wheel's center bore (the hole in the middle of the wheel) matches the diameter of the hub's center flange. This means the wheel is precisely centered on the hub by the hub itself, not just by the lug nuts. Hubcentric wheels are generally preferred, especially for street cars, because they provide better load distribution and reduce the risk of vibrations.

- Lugcentric: In this design, the wheel's center bore is larger than the hub's center flange. The wheel is centered solely by the lug nuts. While lugcentric wheels can work, they are more prone to vibration if the lug nuts aren't tightened perfectly evenly. They're also generally considered less strong than hubcentric wheels.

For most 1989 vehicles, hubcentric is the preferred and often required method. The vehicle was designed with hubcentric wheels in mind, and deviating from this can lead to the problems we discussed earlier.

The Role of Hub Rings

So, what happens if you want to use a wheel that isn't perfectly hubcentric for your car? This is where hub rings come in. Hub rings are small, inexpensive rings made of plastic or aluminum that fill the gap between the wheel's center bore and the hub's center flange. They effectively convert a lugcentric wheel into a hubcentric one.

Using hub rings is generally a good idea if you're running wheels that aren't specifically designed for your car. However, it's important to choose the right size hub ring. The inner diameter of the ring must match the hub's center flange diameter, and the outer diameter must match the wheel's center bore diameter. You can usually find this information online or by consulting with a wheel specialist.

Identifying Hubcentricity Issues

How do you know if you have a hubcentricity problem? Here are some common signs:

- Vibrations: As mentioned earlier, vibrations are a common symptom of improperly centered wheels.

- Difficulty Installing Wheels: If the wheel doesn't easily slide onto the hub, it could indicate a mismatch in center bore diameters.

- Uneven Tire Wear: An improperly centered wheel can cause uneven tire wear.

- Lug Nut Loosening: If your lug nuts are constantly loosening, it could be a sign of improper wheel centering.

Addressing Common Problems with 1989 Vehicles

Now, let's get specific about some common issues owners of 1989 vehicles might face regarding lug patterns and hubcentric requirements.

Original Wheels Are Hard to Find

One of the biggest challenges with older vehicles is finding original replacement parts, including wheels. Original equipment manufacturer (OEM) wheels can be expensive and difficult to source. This often leads owners to consider aftermarket wheels.

Solution: If you're going with aftermarket wheels, be extra diligent about verifying the lug pattern and center bore. Measure the center bore of both the wheel and the hub. If there's a gap, use hub rings of the correct size. Don't be afraid to consult with a wheel specialist to ensure you're getting the right fit.

Corrosion on the Hub

Over time, corrosion can build up on the hub, making it difficult to properly seat the wheel. This is especially common in areas with harsh winters where salt is used on the roads.

Solution: Before installing wheels, thoroughly clean the hub surface with a wire brush to remove any rust or corrosion. You can also apply a thin layer of anti-seize compound to the hub to prevent future corrosion (but be careful not to get any on the lug studs themselves!).

Lug Stud Damage

Over years of use, lug studs can become damaged, either through overtightening or cross-threading. Damaged lug studs are a serious safety hazard and need to be addressed immediately.

Solution: Inspect your lug studs regularly for any signs of damage. If you find a damaged stud, it needs to be replaced. This typically involves removing the wheel hub and pressing out the old stud and pressing in a new one. This is a job best left to a professional mechanic.

Cost Considerations

Finally, let's talk about cost. Here's a rough estimate of what you can expect to pay for some of the repairs and services we've discussed:

- Hub Rings: $10-$30 per set

- Lug Nut Replacement: $1-$5 per lug nut

- Lug Stud Replacement: $50-$150 per stud (including labor)

- Wheel Bearing Replacement: $150-$500 per wheel (including labor)

- Wheel Balancing: $10-$20 per wheel

These are just estimates, and the actual cost will vary depending on your location, the make and model of your vehicle, and the specific repair needed. It's always a good idea to get a quote from a few different shops before committing to any work.

In conclusion, understanding lug patterns and hubcentric requirements is essential for maintaining the safety and performance of your 1989 vehicle. By taking the time to properly inspect your wheels and hubs, and by addressing any issues promptly, you can ensure many more years of enjoyable driving. If you're ever unsure about anything, don't hesitate to consult with a qualified mechanic. We're always happy to help!