1989 Nissan 240sx Wiring Diagram

Hey there, fellow 240sx enthusiast! Let's talk wiring. Owning a 1989 Nissan 240sx is an experience – a blend of classic JDM charm and, let's be honest, the occasional electrical gremlin. Finding a reliable 1989 Nissan 240sx wiring diagram can feel like searching for a unicorn. But don't worry, you're not alone, and we're here to help you navigate that electrical maze.

This article isn't just about throwing a diagram at you. We'll focus on common problems owners face, how to use the wiring diagram to diagnose them, and offer practical solutions. Consider this your troubleshooting roadmap.

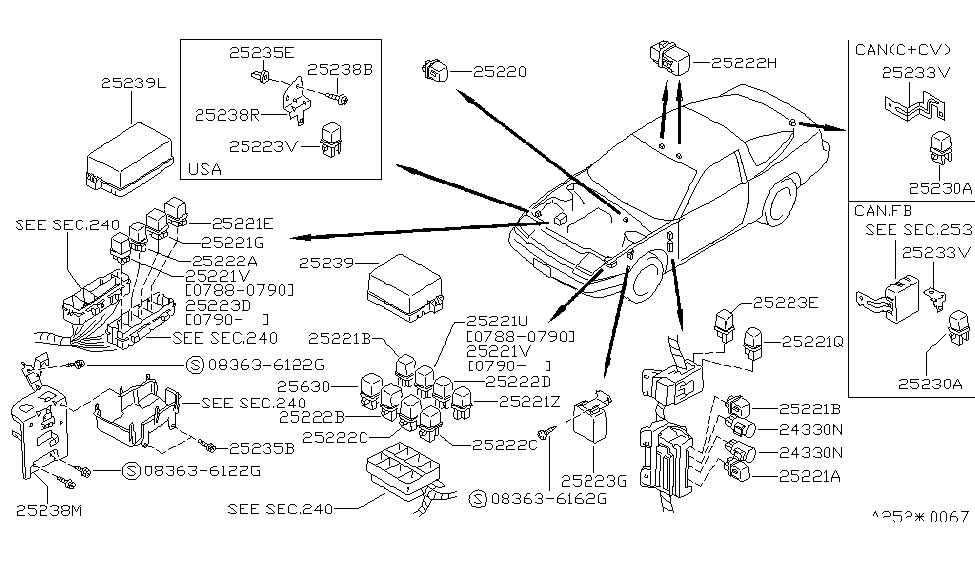

The Importance of a Wiring Diagram

Before we dive into specifics, let's emphasize why a wiring diagram is your best friend. It’s essentially a map of your car's electrical system, showing you how all the components are connected: from the battery to the headlights, the ECU to the sensors. Without it, you're just poking around in the dark, likely causing more harm than good. Trying to fix electrical issues without a diagram is like performing surgery without knowing anatomy. You're going to get lost and potentially cut the wrong wires.

A good wiring diagram will show you:

- Wire colors

- Connector locations

- Fuse and relay positions

- Ground points

- Component locations (sensors, actuators, etc.)

Having this information allows you to trace circuits, identify shorts, and understand how systems are supposed to function. This leads to quicker, more accurate, and ultimately, cheaper repairs.

Common 1989 240sx Electrical Issues and Solutions

Alright, let's get to the meat of the matter. Here are some of the most frequent electrical problems plaguing the 1989 240sx and how a wiring diagram can help you fix them.

Problem 1: Headlights Not Working

A very common issue, especially if you've done any front-end work or the car has been sitting for a while. Several things can cause this:

Diagnosis with Wiring Diagram:

- Check the fuses: Consult the wiring diagram to locate the headlight fuses. A blown fuse is the easiest fix. Use a multimeter to confirm continuity or simply swap it with a known good fuse.

- Inspect the headlight relay: The diagram will show you the location of the headlight relay. Try swapping it with another identical relay (like the horn relay, as a temporary test). If the headlights work, you need a new relay.

- Test the headlight switch: Using the diagram, identify the wires coming from the headlight switch. Use a multimeter to check for continuity between the appropriate terminals when the switch is in the "on" position. No continuity? The switch is likely bad.

- Trace the wiring: Use the wiring diagram to trace the wires from the switch to the relay, and from the relay to the headlights. Look for any breaks, corrosion, or loose connections. Pay special attention to ground points! Corroded ground points are a common culprit in older cars.

Tools Needed: Multimeter, fuse puller, screwdriver, wire stripper/crimper, possibly a test light.

Estimated Repair Cost: Fuse ($1-5), Relay ($10-20), Headlight Switch ($20-50), Wiring Repair (variable, depending on the extent of damage).

Problem 2: Fuel Pump Not Priming

No fuel, no go! If your 240sx won't start and you suspect a fuel delivery issue, the fuel pump is a prime suspect.

Diagnosis with Wiring Diagram:

- Locate the fuel pump relay: The wiring diagram will pinpoint its location. Similar to the headlights, try swapping it with a known good relay.

- Check for power at the fuel pump: Use the diagram to identify the fuel pump connector. With the ignition on (but engine not started), use a multimeter to check for 12V at the connector. No voltage? The problem lies upstream.

- Inspect the fuel pump ground: A bad ground can prevent the fuel pump from working, even if it's receiving power. Consult the wiring diagram to locate the ground point and ensure it's clean and secure.

- Crankshaft Position Sensor (CPS): The ECU needs a signal from the CPS to trigger the fuel pump. The wiring diagram will show you how the CPS is wired. If the CPS or its wiring is faulty, the fuel pump won't prime. Use a multimeter to test the CPS according to the factory service manual specifications.

Tools Needed: Multimeter, screwdriver, socket set, potentially a fuel pressure tester.

Estimated Repair Cost: Relay ($10-20), Fuel Pump ($50-150), CPS ($30-80), Wiring Repair (variable).

Problem 3: Erratic Idle or Poor Performance

Rough idle, stalling, or a general lack of power can often be traced back to sensor issues.

Diagnosis with Wiring Diagram:

- Mass Airflow Sensor (MAF): The MAF sensor is critical for proper fuel injection. The wiring diagram will show you its pinout. Use a multimeter to check the voltage output of the MAF sensor at idle and under load. Compare your readings to the factory service manual specifications. A faulty MAF sensor can cause all sorts of problems.

- Throttle Position Sensor (TPS): The TPS tells the ECU how much the throttle is open. The wiring diagram will show you how to test its output voltage. An improperly adjusted or faulty TPS can lead to idle issues and poor acceleration.

- Oxygen Sensor (O2 Sensor): The O2 sensor provides feedback to the ECU about the exhaust gas composition. The wiring diagram will show you its location and wiring. A failing O2 sensor can cause the engine to run rich or lean, leading to poor fuel economy and performance.

- Coolant Temperature Sensor (CTS): The CTS tells the ECU the engine's temperature. The wiring diagram shows it's location and wiring. A faulty CTS can cause starting problems and poor performance, especially when the engine is cold.

Tools Needed: Multimeter, socket set, screwdrivers, potentially an OBD-I scan tool (if you have one).

Estimated Repair Cost: MAF Sensor ($80-200), TPS ($30-70), O2 Sensor ($30-80), CTS ($15-40), Wiring Repair (variable).

Problem 4: Battery Drain

Waking up to a dead battery is frustrating. Finding the source of a parasitic drain can be tricky, but a wiring diagram is essential.

Diagnosis with Wiring Diagram:

- Perform a parasitic draw test: Disconnect the negative battery terminal and connect a multimeter (set to Amps) between the terminal and the battery cable. You should see a very low reading (typically less than 50mA).

- Isolate circuits: Start pulling fuses one by one. When the current draw drops significantly, you've found the circuit with the problem. The wiring diagram will tell you what components are on that circuit.

- Trace the wiring: Once you've identified the circuit, use the wiring diagram to trace the wires and components. Look for shorts to ground, damaged wiring, or faulty components. Common culprits include the alternator, radio, interior lights, and alarm system.

Tools Needed: Multimeter, socket set, fuse puller.

Estimated Repair Cost: Variable, depending on the source of the drain. Could be as simple as a faulty door switch ($10-20) or as complex as a bad alternator ($100-300) or a short in the wiring harness (variable).

Finding a Reliable Wiring Diagram

Now, where do you find this magical wiring diagram? Here are a few options:

- Factory Service Manual (FSM): This is the holy grail. The FSM contains the most accurate and complete wiring diagrams. You can often find digital versions online (sometimes for free, sometimes for a small fee). Check 240sx enthusiast forums and online parts retailers.

- Haynes or Chilton Manuals: These are less detailed than the FSM, but they still contain useful wiring diagrams. They're readily available at auto parts stores.

- Online Resources: Some websites specialize in providing wiring diagrams for various vehicles. However, be cautious and verify the accuracy of the diagrams before using them.

Important Tip: Make sure the wiring diagram you're using is specifically for a 1989 Nissan 240sx and, if possible, for the exact trim level (SE or base model). There can be slight variations between years and trims.

Final Thoughts and Tips

Working with automotive electrical systems can be intimidating, but with a good wiring diagram and a methodical approach, you can tackle many common problems yourself. Remember these key tips:

- Safety First: Always disconnect the negative battery terminal before working on the electrical system.

- Use Quality Tools: Invest in a good multimeter, wire strippers, and crimpers. Cheap tools can lead to inaccurate readings and damaged wiring.

- Take Your Time: Don't rush the process. Carefully trace the circuits and double-check your work.

- Clean Connections: Corroded connections are a major cause of electrical problems. Clean all connections thoroughly with a wire brush or sandpaper.

- Document Everything: Take notes and pictures as you work. This will help you remember what you've done and make it easier to troubleshoot future problems.

If you're not comfortable working with electrical systems, it's always best to consult a qualified mechanic. However, with the knowledge and tools outlined in this article, you should be well-equipped to diagnose and fix many common electrical issues on your 1989 Nissan 240sx. Good luck and happy wrenching!