1991 Nissan 240sx Bolt Pattern

Alright, let's talk about the bolt pattern on the 1991 Nissan 240SX. If you're planning on swapping wheels, upgrading your brakes, or even just doing some basic maintenance, understanding this specification is absolutely crucial. Getting it wrong can lead to serious safety issues, so pay close attention!

The 1991 Nissan 240SX Bolt Pattern: 4x114.3 (4x4.5)

The 1991 Nissan 240SX, in all its factory configurations, utilizes a 4x114.3mm bolt pattern. You might also see this referred to as 4x4.5 inches. Both are equivalent and describe the same thing. Let's break down what this means:

- "4" signifies the number of lug nuts or bolts that secure the wheel to the hub. In this case, there are four.

- "114.3mm" (or "4.5 inches") refers to the diameter of the circle formed by the centers of these four lug holes. This is known as the pitch circle diameter (PCD).

It's essential to understand that these numbers must match precisely when selecting new wheels. Attempting to force a wheel with the wrong bolt pattern onto your 240SX can damage the wheel studs, compromise the wheel's structural integrity, and create a severely unsafe driving condition.

Why is the Bolt Pattern Important?

The bolt pattern is more than just a dimension; it's a critical safety component. Here's why:

- Proper Load Distribution: The bolt pattern ensures that the weight of the vehicle and the forces experienced during driving (acceleration, braking, cornering) are evenly distributed across the lug nuts and wheel studs.

- Wheel Centering: The correct bolt pattern guarantees that the wheel is properly centered on the hub. This prevents vibrations and ensures smooth, stable handling.

- Stud Integrity: Using the wrong bolt pattern can place undue stress on the wheel studs, leading to fatigue, cracking, and eventual failure. A broken wheel stud at speed can have catastrophic consequences.

Measuring the Bolt Pattern

While it's best to rely on documented specifications like the one we've provided, understanding how to measure a bolt pattern can be useful in certain situations, especially if you're dealing with unmarked wheels or unknown components. Here's how to do it on a 4-lug setup:

- Measure Center-to-Center: Using a ruler or, preferably, a set of calipers, measure the distance between the center of one lug hole and the center of the lug hole directly opposite it.

- Convert to Millimeters (if necessary): If you measured in inches, multiply the measurement by 25.4 to convert it to millimeters.

For a 4-lug pattern, this single measurement is sufficient to determine the PCD. In our case, measuring from the center of one stud to the center of the opposite stud should yield approximately 114.3mm (or 4.5 inches).

Common Mistakes and Misconceptions

There are a few common pitfalls to avoid when dealing with bolt patterns:

- "Close Enough" Isn't Good Enough: Don't be tempted to use a wheel with a bolt pattern that's "close" but not exact. Even a slight difference can compromise safety.

- Universal Wheels: Be wary of "universal" wheels that claim to fit multiple bolt patterns. These often use slotted lug holes, which can introduce play and reduce the strength of the wheel mounting system.

- Incorrect Conversion: Ensure you're using the correct conversion factor (25.4mm per inch) when converting between inches and millimeters.

- Forgetting the Hub Bore: While this article focuses on bolt patterns, don't forget about the hub bore. This is the center hole in the wheel that fits over the hub on your car. The hub bore must be the correct size to ensure proper centering and load distribution. An incorrect hub bore can cause vibrations and, in extreme cases, wheel separation. If the hub bore of your aftermarket wheel is larger than the hub on your car, you can use hub-centric rings to achieve a proper fit.

Adapters and Spacers: Proceed with Caution

Wheel adapters and wheel spacers can be used to change the bolt pattern or offset of your wheels. However, it's crucial to use them responsibly and understand the potential risks. Wheel adapters allow you to mount wheels with a different bolt pattern than your vehicle's hubs, while wheel spacers push the wheels further out from the hub, altering the track width.

Using adapters to change the bolt pattern should be carefully considered and only performed when absolutely necessary. High-quality adapters from reputable manufacturers are essential. Always ensure the adapter is properly installed and torqued to the manufacturer's specifications.

Here are some important considerations when using adapters and spacers:

- Quality Matters: Purchase adapters and spacers from a reputable manufacturer known for producing high-quality, durable products. Avoid cheap imitations, as they may be prone to failure.

- Thickness and Stud Length: The thickness of the adapter or spacer will affect the length of the wheel studs required. Ensure that you have sufficient stud engagement to safely secure the wheel. Extended studs may be necessary.

- Proper Installation: Follow the manufacturer's instructions carefully when installing adapters and spacers. Use a torque wrench to tighten the lug nuts to the specified torque. Re-torque the lug nuts after a short driving distance (typically 50-100 miles).

- Potential Drawbacks: Adapters and spacers can introduce additional stress on the wheel bearings and suspension components. They can also alter the handling characteristics of the vehicle.

Verifying Wheel Fitment

Before committing to a set of wheels, it's always a good idea to test-fit them on your 240SX. This involves temporarily mounting the wheels without tires to check for any clearance issues with the suspension, brakes, or bodywork. Pay close attention to the following:

- Brake Caliper Clearance: Ensure that the wheel spokes clear the brake calipers.

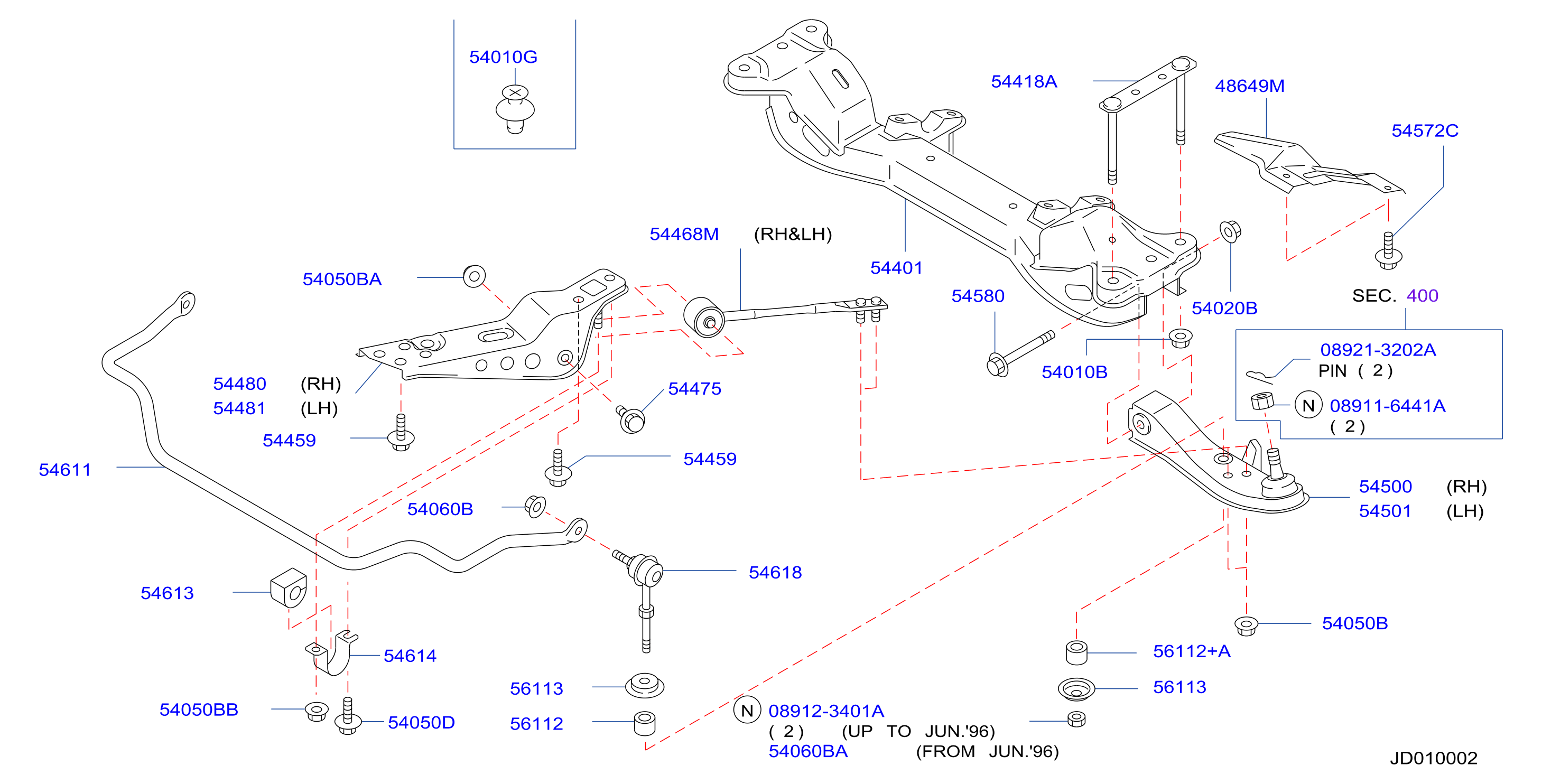

- Suspension Clearance: Check for any rubbing or interference with the suspension components, such as the struts, springs, or control arms.

- Fender Clearance: Make sure that the wheel and tire combination will not rub against the fenders, especially when the suspension is compressed.

If you encounter any clearance issues, you may need to consider using wheel spacers, rolling or pulling the fenders, or choosing a different wheel with a more suitable offset.

Torque Specifications

Once you've verified the correct bolt pattern and fitment, it's crucial to tighten the lug nuts to the manufacturer's specified torque. Using a torque wrench is essential for ensuring proper clamping force and preventing over-tightening, which can damage the studs. For the 1991 Nissan 240SX, the recommended lug nut torque is typically around 80 ft-lbs (108 Nm). However, always consult your vehicle's service manual or a reliable source to confirm the correct torque specification. After the initial torque, re-torque the lug nuts after approximately 50-100 miles of driving.

Conclusion

Understanding the bolt pattern of your 1991 Nissan 240SX is essential for safe and proper wheel fitment. Always double-check the bolt pattern before purchasing new wheels, and be cautious when using adapters or spacers. Proper installation and torqueing of lug nuts are also critical for ensuring wheel security and preventing potential accidents. By following these guidelines, you can confidently choose the right wheels for your 240SX and enjoy a safe and enjoyable driving experience.