1992 Nissan 240sx Distributor: Common Issues And Solutions

The 1992 Nissan 240SX, a beloved sports coupe, remains a popular choice among car enthusiasts. While known for its handling and potential for modification, like any vehicle of its age, it's prone to certain issues. One common area of concern is the distributor. This article dives deep into the common problems associated with the 1992 Nissan 240SX distributor and provides solutions to help you keep your ride running smoothly.

Understanding the Distributor's Role in the 1992 Nissan 240SX

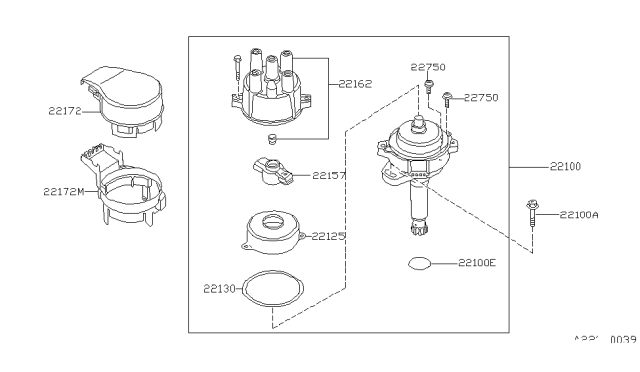

Before tackling the problems, it's essential to understand the distributor's function in the 1992 Nissan 240SX's KA24DE engine. The distributor's primary job is to distribute high-voltage electricity from the ignition coil to the correct spark plugs in the correct firing order. This precisely timed spark is what ignites the air-fuel mixture in the cylinders, creating the power that drives your car. It also houses the ignition module and often, the camshaft position sensor (CAS), which are critical for engine timing and fuel injection.

A properly functioning distributor is crucial for optimal engine performance. When it malfunctions, it can lead to a range of drivability issues, from misfires to a complete no-start condition.

Common Issues with the 1992 Nissan 240SX Distributor

Several factors can contribute to distributor problems in the 1992 Nissan 240SX. Given the age of these vehicles, wear and tear is a significant factor. Here are some of the most frequent issues:

1. Worn Distributor Cap and Rotor

The distributor cap and rotor are mechanical components that physically distribute the high-voltage spark. Over time, these parts wear down due to constant electrical arcing and environmental exposure. Signs of a worn distributor cap and rotor include:

- Cracks or carbon tracking on the distributor cap: Cracks allow moisture to enter, disrupting the spark, while carbon tracking (black lines) provides an easier path for the spark to ground, leading to misfires.

- Corrosion on the rotor button or terminals: Corrosion impedes the flow of electricity.

- Burnt or eroded rotor tip: A worn rotor tip can't efficiently transfer the spark.

Solution: Regularly inspect the distributor cap and rotor for wear. Replace them as part of your routine maintenance, typically every 30,000-50,000 miles, or sooner if you notice any of the above symptoms. High-quality aftermarket options are available, but ensure they meet or exceed OEM specifications.

2. Faulty Ignition Module

The ignition module, often located inside the distributor, controls the spark timing and dwell. When it fails, it can cause a variety of problems:

- Intermittent misfires: The engine may run fine sometimes and misfire at other times.

- Rough idling: The engine may idle unevenly or stall.

- Complete engine failure: In severe cases, a faulty ignition module can prevent the engine from starting altogether.

Solution: Diagnosing a faulty ignition module typically requires a multimeter and some electrical knowledge. You can test the module's resistance and voltage to determine if it's functioning correctly. If it's faulty, replacement is the only option. Be sure to use a quality replacement part.

3. Camshaft Angle Sensor (CAS) Failure

The Camshaft Angle Sensor (CAS), often integrated into the distributor on the 1992 Nissan 240SX, provides the engine control unit (ECU) with information about the camshaft's position. This information is crucial for proper fuel injection and ignition timing. A failing CAS can cause:

- Difficulty starting: The engine may crank but not start.

- Poor fuel economy: Incorrect timing can lead to inefficient combustion.

- Check engine light (CEL): A faulty CAS will often trigger a CEL with a corresponding diagnostic trouble code (DTC).

- Erratic engine performance: Stuttering, hesitation, or surging during acceleration.

Solution: A scan tool can help identify CAS-related DTCs. You can also check the CAS wiring and connectors for damage. If the CAS is faulty, replacement is necessary. When replacing the CAS, it's absolutely critical to ensure the timing is set correctly. Incorrect timing can lead to severe engine damage.

4. Distributor Bearing Wear

The distributor shaft rotates on bearings. Over time, these bearings can wear, causing the distributor shaft to wobble. This wobble can affect the accuracy of the timing and lead to misfires and other performance problems.

- Noisy distributor: A worn distributor bearing may produce a grinding or squealing noise.

- Erratic timing: The timing may fluctuate, causing performance issues.

Solution: Replacing the distributor bearings can be a complex task, often requiring specialized tools. In most cases, it's more cost-effective and easier to replace the entire distributor with a new or remanufactured unit.

5. Oil Leaks

Oil can leak from the distributor, either from the O-ring where it mounts to the engine or from internal seals. Oil leaks can cause:

- Oil consumption: You may notice that your engine is using more oil than usual.

- Messy engine bay: Oil leaks can create a dirty and unsightly engine bay.

- Potential for electrical problems: Oil can contaminate the distributor cap and rotor, leading to misfires.

Solution: Replace the O-ring or seals causing the leak. If the leak is severe or internal seals are failing, replacing the entire distributor may be the best option.

6. Wiring and Connector Issues

The wiring and connectors that connect to the distributor can become damaged or corroded over time. This can disrupt the electrical signals and cause a variety of problems.

- Intermittent problems: The engine may run fine sometimes and experience problems at other times.

- Difficulty starting: A broken wire or corroded connector can prevent the engine from starting.

Solution: Carefully inspect the wiring and connectors for damage. Clean corroded connectors with electrical contact cleaner. Repair or replace damaged wires. A wiring diagram for the 1992 Nissan 240SX can be a valuable tool for troubleshooting wiring problems.

Troubleshooting Tips for 1992 Nissan 240SX Distributor Problems

When diagnosing distributor problems, it's helpful to follow a systematic approach:

- Visual Inspection: Start by visually inspecting the distributor cap, rotor, wiring, and connectors for any signs of damage or wear.

- Check for Spark: Use a spark tester to verify that the spark plugs are receiving a strong spark. If there's no spark, the problem likely lies within the ignition system, potentially the distributor, ignition coil, or ignition module.

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-I scanner to check for any DTCs that may be related to the distributor or ignition system.

- Test the Ignition Module and CAS: Use a multimeter to test the ignition module and CAS according to the manufacturer's specifications.

- Check the Timing: Use a timing light to verify that the ignition timing is set correctly.

Replacing the 1992 Nissan 240SX Distributor

If you determine that the distributor needs to be replaced, here's a general overview of the process. Important: Consult a repair manual specific to your 1992 Nissan 240SX for detailed instructions and safety precautions.

- Disconnect the negative battery cable.

- Remove the distributor cap and rotor.

- Disconnect the wiring harness from the distributor.

- Mark the position of the distributor housing on the engine block. This is crucial for maintaining the correct timing.

- Remove the distributor hold-down bolt.

- Carefully remove the distributor from the engine.

- Install the new distributor, aligning it with the mark you made earlier.

- Install the distributor hold-down bolt.

- Connect the wiring harness to the distributor.

- Install the distributor cap and rotor.

- Connect the negative battery cable.

- Use a timing light to verify and adjust the ignition timing. This is a critical step.

Note: Due to the complexity involved in setting the timing accurately, consider having a qualified mechanic perform the distributor replacement and timing adjustment. Incorrect timing can lead to poor performance or engine damage.

Preventative Maintenance for Your 1992 Nissan 240SX Distributor

Preventative maintenance is key to extending the life of your 1992 Nissan 240SX distributor. Here are some tips:

- Regularly inspect the distributor cap and rotor for wear and tear.

- Replace the distributor cap and rotor as part of your routine maintenance.

- Keep the engine bay clean to prevent corrosion and damage to electrical components.

- Check the distributor for oil leaks and address them promptly.

- Ensure proper ventilation around the distributor to prevent overheating.

Conclusion

The distributor is a vital component of the 1992 Nissan 240SX's engine. By understanding the common problems associated with the distributor and following the troubleshooting and maintenance tips outlined in this article, you can help keep your 240SX running smoothly and reliably for years to come. Remember that when in doubt, consult a qualified mechanic to diagnose and repair any complex issues. Keeping your 240SX in top condition will ensure that you can continue to enjoy its performance and handling for years to come.