1993 Nissan 240sx Convertible Top Mechanism Operation

Alright, let's dive into the 1993 Nissan 240SX convertible top mechanism. This system, while seemingly simple on the surface, involves a series of interconnected components that need to work in harmony for smooth operation. We'll break down the hydraulics, electrical controls, and mechanical linkages so you can understand how it all ticks. This guide assumes you have some basic mechanical knowledge and are comfortable working on your vehicle.

Hydraulic System: The Muscle of the Operation

The 240SX convertible top relies on a hydraulic system to provide the necessary force to raise and lower the top. The main components are:

- Hydraulic Pump and Motor: This is the heart of the system. Located typically in the trunk, often near the spare tire well, the electric motor drives the hydraulic pump. The pump generates hydraulic pressure, which is then directed to the hydraulic cylinders. It's essential to check the fluid level in the reservoir regularly. Low fluid can lead to slow operation, jerky movements, or even complete failure. We'll talk about fluid types later.

- Hydraulic Cylinders (Actuators): These are the linear actuators that do the actual work of moving the top. The 240SX typically has multiple cylinders: One or two main cylinders that lift and lower the main portion of the top frame, and possibly smaller cylinders that assist in latching/unlatching the top from the windshield header. These cylinders contain pistons that move within the cylinder bore. As hydraulic fluid is forced into the cylinder, the piston moves, extending the cylinder rod. This rod is connected to a linkage, which in turn moves the top frame.

- Hydraulic Lines (Hoses): These hoses carry the pressurized hydraulic fluid from the pump to the cylinders and back to the reservoir. They are high-pressure lines and need to be in good condition. Check for cracks, leaks, or kinks. A burst hose can create a significant mess and render the top inoperable.

- Hydraulic Control Valve (Valve Body): This valve directs the flow of hydraulic fluid to the appropriate cylinders, depending on whether you are raising or lowering the top. It's controlled by electrical signals from the top control module. The valve contains solenoids that open and close passages within the valve body. A malfunctioning valve can cause the top to operate erratically or not at all.

- Hydraulic Fluid Reservoir: This holds the hydraulic fluid that powers the system. It's crucial to use the correct type of hydraulic fluid specified in the owner's manual or a service manual. Using the wrong fluid can damage the seals and other components in the system. Typically, a mineral oil-based hydraulic fluid is used.

Understanding the flow of hydraulic fluid is key. When you activate the top switch, the control module energizes the pump motor and the appropriate solenoids in the control valve. The pump then draws fluid from the reservoir, pressurizes it, and sends it through the selected lines to the cylinders. As the cylinders extend or retract, they move the top frame. The fluid displaced from the cylinders returns to the reservoir through other lines.

Electrical Control System: The Brains of the Operation

The electrical control system manages the entire top operation. It's responsible for activating the hydraulic pump, controlling the direction of the hydraulic fluid, and ensuring safety by monitoring various sensors.

- Convertible Top Switch: This is your interface to the system. It signals the control module to either raise or lower the top.

- Convertible Top Control Module (TCU): The "brain" of the operation. This module receives signals from the top switch and various sensors, and then controls the hydraulic pump and control valve accordingly. It also monitors for faults and can disable the system if a problem is detected. Often located under the dash.

- Limit Switches/Position Sensors: These sensors provide feedback to the control module about the position of the top. They are typically located at various points along the top's range of motion, such as the fully open position, the fully closed position, and potentially intermediate positions. These switches are crucial for preventing the top from over-traveling or damaging itself. A common problem is bent or misaligned limit switch arms.

- Wiring Harness: The wiring harness connects all the electrical components together. Check for damaged wires, corroded connectors, and loose connections. A multimeter can be invaluable for tracing electrical faults.

- Relays: Relays act as electrical switches, allowing a small current to control a larger current. They are used to control the hydraulic pump motor and other high-current components.

The control module uses a series of inputs from the top switch and the position sensors to determine the desired action. It then activates the hydraulic pump and control valve to move the top in the correct direction. If any of the sensors are malfunctioning, the control module may prevent the top from operating to avoid damage. This is a safety feature.

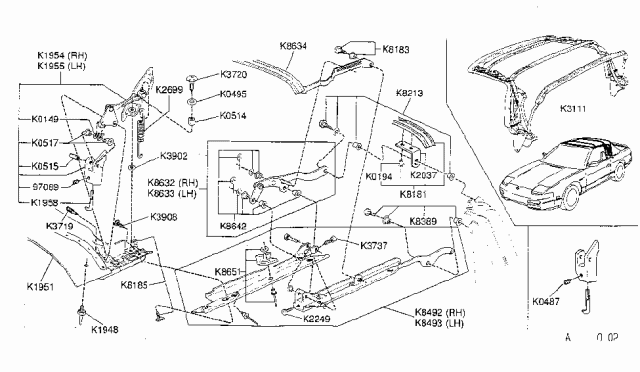

Mechanical Linkages: Translating Force into Motion

The hydraulic cylinders don't directly move the top. Instead, they act on a series of mechanical linkages that translate the linear motion of the cylinders into the rotational motion required to raise and lower the top. These linkages are crucial for ensuring that the top moves smoothly and evenly.

- Top Frame: This is the main structural component of the convertible top. It's made up of several interconnected bows that provide support for the fabric top.

- Linkage Arms: These arms connect the hydraulic cylinders to the top frame. They are designed to provide the correct leverage and geometry to move the top efficiently.

- Pivot Points: These are the points where the linkage arms connect to the top frame and the hydraulic cylinders. They need to be well-lubricated to ensure smooth movement. Grease fittings are sometimes provided.

- Latches: These are the mechanisms that secure the top to the windshield header when it's in the closed position. They are typically operated by a separate hydraulic cylinder or manually. Ensure they are properly adjusted for a tight seal.

Understanding how the linkages work together is important for troubleshooting. If the top is binding or moving unevenly, it could be due to a bent linkage arm, a seized pivot point, or a misadjusted latch. Careful inspection and lubrication can often resolve these issues.

Troubleshooting Tips

Here are some common problems and potential solutions:

- Top Doesn't Move at All:

- Check the fuse for the convertible top system.

- Check the hydraulic fluid level.

- Check the wiring connections to the hydraulic pump and control module.

- Verify the top switch is functioning correctly using a multimeter.

- Listen for the hydraulic pump motor running when the top switch is activated. If it doesn't run, the motor may be faulty.

- Top Moves Slowly or Jerkily:

- Check the hydraulic fluid level.

- Check for leaks in the hydraulic lines.

- Bleed the hydraulic system to remove any air. This process usually involves opening bleed screws on the cylinders while operating the top. Consult a service manual for the correct procedure.

- Inspect the hydraulic cylinders for leaks.

- Top Stops Partway Through Operation:

- Check the limit switches/position sensors. Ensure they are properly aligned and functioning. Use a multimeter to test their continuity.

- Check for obstructions in the top's path.

- The control module may be detecting a fault and stopping the operation.

- Hydraulic Fluid Leaks:

- Identify the source of the leak. Check the hydraulic lines, cylinders, and pump.

- Replace any damaged hoses or seals.

- Ensure all fittings are properly tightened.

Important Notes:

- Safety First: Always disconnect the battery before working on the electrical system. When working on the hydraulic system, be aware that the fluid is under pressure. Relieve the pressure before disconnecting any lines.

- Service Manual: Invest in a good service manual. It will provide detailed diagrams, troubleshooting procedures, and torque specifications.

- Cleanliness: Keep the hydraulic system clean. Dirt and debris can damage the pump and valves.

- Correct Fluid: Use the correct type of hydraulic fluid.

- Patience: Troubleshooting the convertible top system can be time-consuming. Be patient and methodical.

By understanding the different components of the 1993 Nissan 240SX convertible top mechanism and how they work together, you can effectively troubleshoot and repair common problems. Remember to always prioritize safety and consult a service manual for detailed instructions. Good luck!