1995 Fuel Pump Flow Rate And Electrical Requirements

Alright folks, let's dive into the nitty-gritty of 1995 fuel pump flow rates and electrical requirements. This is crucial information whether you're troubleshooting a sputtering engine, planning a performance upgrade, or just trying to understand how your fuel system works. We'll focus primarily on generic systems common in 1995 vehicles, acknowledging that specific makes and models may have slight variations. Always consult your vehicle's service manual for precise details.

Fuel Pump Flow Rate: The Heart of the Matter

First, let's define flow rate. Simply put, it's the volume of fuel the pump can deliver in a given time, usually measured in liters per hour (LPH) or gallons per hour (GPH). A sufficient flow rate ensures your engine receives the necessary fuel to maintain proper combustion under all operating conditions – idle, acceleration, and cruising. If the fuel pump can't keep up with the engine's demand, you'll experience fuel starvation, leading to poor performance, hesitation, and potential engine damage.

Understanding Flow Rate Requirements

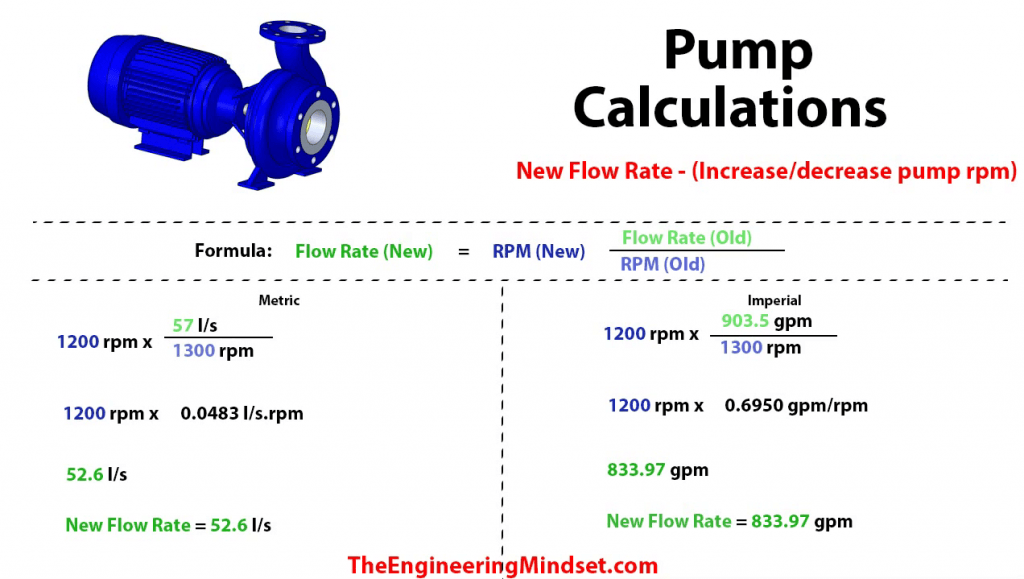

Determining the required flow rate for your 1995 vehicle isn't an exact science without specialized equipment, but we can estimate based on engine horsepower (HP). Generally, a naturally aspirated (non-turbocharged or supercharged) gasoline engine requires approximately 0.5 pounds of fuel per horsepower per hour (lbs/HP/hr). Let's break that down:

- Determine Engine Horsepower: Find the factory-rated horsepower for your engine. This information is usually in your owner's manual or easily searchable online.

- Calculate Fuel Demand: Multiply your engine's horsepower by 0.5 (lbs/HP/hr). This gives you the total fuel demand in pounds per hour.

- Convert to Gallons Per Hour (GPH): Divide the pounds per hour by the fuel density of gasoline, which is approximately 6 pounds per gallon. So, (lbs/hr) / 6 = GPH.

- Convert to Liters Per Hour (LPH): Multiply the GPH by 3.785. So, GPH * 3.785 = LPH.

Example: Let's say your 1995 engine produces 200 HP.

- Fuel Demand: 200 HP * 0.5 lbs/HP/hr = 100 lbs/hr

- GPH: 100 lbs/hr / 6 lbs/gallon = 16.67 GPH

- LPH: 16.67 GPH * 3.785 = 63.1 LPH

Therefore, you'd need a fuel pump capable of delivering at least 63.1 LPH. It's always better to err on the side of caution and choose a fuel pump with a slightly higher flow rate than calculated. This provides a safety margin and accommodates future modifications.

Typical 1995 Fuel Pump Flow Rates

Most fuel pumps in 1995 vehicles ranged from approximately 50 LPH to 90 LPH, depending on the engine size and performance level. Smaller, four-cylinder engines generally used pumps on the lower end of that range, while larger V6 or V8 engines required pumps with higher flow rates. Remember, this is a generalization; always verify the specific requirements for your vehicle.

Important Note: Fuel pump manufacturers typically publish flow rates at a specific fuel pressure (e.g., 43.5 PSI). The actual flow rate delivered by the pump will decrease as fuel pressure increases. This is something to consider when choosing a pump, especially if you plan to increase fuel pressure for performance reasons.

Fuel Pump Electrical Requirements: Voltage, Amperage, and Wiring

Now, let's switch gears and discuss the electrical side of things. Understanding the voltage, amperage, and wiring requirements of your fuel pump is critical for ensuring proper operation and preventing electrical failures.

Voltage

Most 1995 vehicles utilize a 12-volt electrical system, and the fuel pump is designed to operate at this voltage. However, voltage drops can occur along the wiring harness, especially with older vehicles. A significant voltage drop can reduce the fuel pump's performance and potentially lead to premature failure. It's good practice to measure the voltage at the fuel pump connector while the pump is running. Ideally, it should be as close to 12 volts as possible.

Amperage

Amperage, or current draw, is the amount of electricity the fuel pump consumes. A typical 1995 fuel pump might draw anywhere from 5 to 10 amps while operating under normal conditions. The exact amperage draw will depend on the pump's design, flow rate, and fuel pressure. Excessive amperage draw can indicate a problem with the pump, such as a worn motor or internal blockage.

Wiring and Relays

The fuel pump circuit typically includes a relay, a fuse, and various wiring connections. The relay acts as a switch, allowing a small electrical signal from the engine control unit (ECU) to control the high-current circuit that powers the fuel pump. The fuse protects the circuit from overcurrent situations. A blown fuse or faulty relay is a common cause of fuel pump failure.

Here's a simplified overview of a typical 1995 fuel pump circuit:

- Battery: Provides the power source.

- Ignition Switch: Activates the fuel pump circuit when the key is turned to the "on" position.

- ECU: Controls the fuel pump relay based on engine operating conditions.

- Fuel Pump Relay: Switches the high-current circuit to power the fuel pump.

- Fuel Pump Fuse: Protects the circuit from overcurrent.

- Fuel Pump: Pumps fuel from the fuel tank to the engine.

- Ground: Completes the electrical circuit.

Common Wiring Issues:

- Corrosion: Over time, corrosion can build up on wiring connectors, increasing resistance and reducing voltage to the fuel pump.

- Damaged Wiring: Cracked or frayed wires can cause shorts or open circuits.

- Faulty Ground Connection: A poor ground connection can prevent the fuel pump from operating properly.

Upgrading Your Fuel Pump

If you're modifying your 1995 engine for increased performance, you'll likely need to upgrade your fuel pump to provide a higher flow rate. When choosing an aftermarket fuel pump, be sure to consider the following:

- Flow Rate: Select a pump with a flow rate that matches or exceeds your engine's fuel demand.

- Fuel Pressure: Ensure the pump can maintain the desired fuel pressure at the required flow rate.

- Electrical Compatibility: Verify that the pump is compatible with your vehicle's electrical system. Higher-flowing pumps often draw more amperage and may require upgrading the wiring and relay.

- Fuel Type Compatibility: Ensure the pump is compatible with the type of fuel you'll be using (e.g., gasoline, E85).

Warning: Installing a fuel pump that draws significantly more amperage than the original pump can overload the existing wiring and potentially cause a fire. Always upgrade the wiring and relay if necessary. Consult a qualified mechanic or electrician if you're unsure about how to do this safely.

Troubleshooting Fuel Pump Problems

If you suspect a problem with your fuel pump, here are some common symptoms and troubleshooting steps:

- Engine Won't Start: Check the fuel pump fuse and relay. Listen for the fuel pump priming noise (a brief buzzing sound) when you turn the key to the "on" position. If you don't hear the pump, it may be faulty.

- Poor Performance/Hesitation: This can indicate a fuel pump that's not delivering enough fuel. Check the fuel pressure at the fuel rail.

- Stalling: Stalling can be caused by fuel starvation, which can be due to a faulty fuel pump, clogged fuel filter, or fuel pressure regulator.

- Fuel Pump Noise: Excessive noise from the fuel pump can indicate wear or damage.

Tools You'll Need:

- Multimeter: For measuring voltage and amperage.

- Fuel Pressure Gauge: For measuring fuel pressure at the fuel rail.

- Wiring Diagram: To help you trace the fuel pump circuit.

By understanding the fuel pump flow rate and electrical requirements of your 1995 vehicle, you'll be better equipped to diagnose and repair fuel system problems, as well as make informed decisions about performance upgrades. Remember to always prioritize safety and consult your vehicle's service manual for specific instructions.