1995 Nissan 240sx Headlight Assembly Specifications And Beam Pattern Analysis

Okay, so you're having some trouble with your 1995 Nissan 240SX headlights. Let's get this sorted. Whether you're dealing with dim lights, a misaligned beam pattern, or just plain broken assemblies, understanding the specs and how the system works is the first step toward fixing the problem. This guide will help you diagnose common issues and hopefully point you in the right direction for a solution.

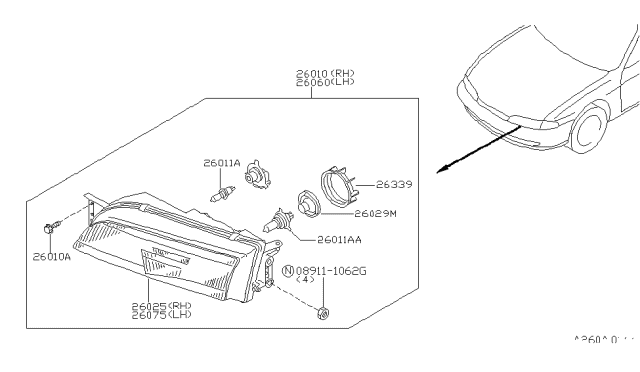

Understanding the 1995 240SX Headlight Assembly

The 1995 240SX uses a sealed beam headlight system. This means the bulb and lens are integrated into a single, replaceable unit. While this design is relatively simple, it's still crucial to understand the specifications to ensure you're using the correct parts and achieving proper illumination.

Headlight Bulb Type and Wattage

The stock 1995 240SX headlight uses a H4656 sealed beam headlight. This is a rectangular headlight. It's important to use the correct bulb type as others may not fit properly or have the correct beam pattern. The standard wattage for these bulbs is typically 35/55 watts (low beam/high beam). Using higher wattage bulbs can overload the wiring and potentially melt the headlight housing or damage the electrical system. Stick to the recommended wattage!

Alternative bulb types, depending on aftermarket modification, could include H4 conversions. These kits replace the sealed beam with a replaceable H4 bulb and a reflector housing. If you have one of these, you'll need to identify the specific H4 bulb type (usually 55/60W). If unsure, check the housing for markings or consult the kit manufacturer's documentation.

Housing and Lens Material

The original headlight housing is typically made of a durable plastic, and the lens is made of glass. Over time, the plastic can become brittle and the lens can become cloudy or yellowed due to UV exposure. This can significantly reduce light output. Cracks or damage to the housing can also allow moisture to enter, causing further issues like corrosion.

Beam Pattern Analysis and Adjustment

A proper headlight beam pattern is essential for safe driving, providing adequate visibility without blinding oncoming drivers. The 240SX's headlight beam pattern should follow a standardized pattern, typically with a slight downward and outward angle.

Typical Beam Pattern Characteristics

The low beam should illuminate the road directly in front of the vehicle and to the right side, extending a reasonable distance without projecting too high. The high beam should provide a longer, more focused beam of light for improved visibility at higher speeds or in dark rural areas. Both beams should have a clear cutoff line to avoid blinding oncoming traffic.

Symptoms of a Misaligned Beam

- Poor Visibility: Difficulty seeing the road clearly, especially at night.

- Blinding Oncoming Drivers: Frequent flashing from other drivers indicating your headlights are too high.

- Uneven Illumination: One headlight shines higher or lower than the other.

- Patches of Darkness: Dark spots or areas with reduced visibility in the beam pattern.

Headlight Adjustment Procedure

Adjusting the headlights on a 240SX is relatively straightforward. You'll need a Phillips head screwdriver and a level surface, like a garage floor. It's best to do this at night or in a dimly lit area to clearly see the beam pattern.

- Preparation: Park the car on a level surface, approximately 25 feet away from a wall or garage door. Ensure the tires are properly inflated and the vehicle is not carrying any heavy loads.

- Marking the Wall: Measure the height of the headlight centers from the ground and mark this height on the wall with tape. Draw a horizontal line across the wall at this height. This will be your reference line.

- Vertical Adjustment: Locate the vertical adjustment screw on the headlight assembly. Typically, there's an adjuster screw located on the top or side of the headlight assembly. Turn the screw clockwise or counterclockwise to raise or lower the beam. Aim the top of the brightest part of the low beam pattern slightly below the reference line on the wall.

- Horizontal Adjustment: Locate the horizontal adjustment screw, which is usually on the side of the headlight assembly. Turn the screw to move the beam left or right. Align the brightest part of the low beam pattern with the center of the headlight (or slightly to the right, depending on your local regulations).

- Fine-Tuning: Repeat steps 3 and 4 for the other headlight. After adjusting both headlights, drive the car at night to test the beam pattern and make any further adjustments as needed.

Tools Needed for Adjustment

- Phillips head screwdriver

- Measuring tape

- Level surface

- Masking tape

Common Problems and Solutions

Let's address some common issues you might encounter with your 240SX headlights:

Dim Headlights

Possible Causes:

- Oxidized/Corroded Connections: Check the headlight connectors and ground connections for corrosion. Clean them with electrical contact cleaner and apply dielectric grease to prevent future corrosion.

- Old Bulbs: Headlight bulbs lose brightness over time. Replace the bulbs with new ones.

- Voltage Drop: A voltage drop in the wiring can reduce the brightness of the headlights. Use a multimeter to check the voltage at the headlight connectors. If the voltage is significantly lower than battery voltage, trace the wiring to identify the source of the voltage drop (e.g., corroded connections, damaged wiring).

- Faulty Ground: A poor ground connection can also cause dim headlights. Ensure the ground connections are clean and secure.

Solution: Clean connections, replace bulbs, trace wiring for voltage drops, and ensure proper grounding.

Headlights Not Working

Possible Causes:

- Blown Fuse: Check the headlight fuse in the fuse box. Replace the fuse with a new one of the same amperage.

- Faulty Headlight Switch: The headlight switch may be faulty. Use a multimeter to test the switch for continuity. If the switch is faulty, replace it.

- Faulty Headlight Relay: Some 240SX models have a headlight relay. If the relay is faulty, replace it.

- Broken Wiring: Check the wiring for damage, such as cuts or breaks. Repair or replace any damaged wiring.

Solution: Check/replace fuses, test/replace headlight switch, test/replace headlight relay, inspect/repair wiring.

Cloudy or Yellowed Headlight Lenses

Possible Causes:

- UV Exposure: Prolonged exposure to sunlight can cause the headlight lenses to become cloudy or yellowed.

Solution:

Headlight Restoration Kit: Use a headlight restoration kit to remove the oxidation and restore the clarity of the lenses. These kits typically include sandpaper, polishing compounds, and a UV protectant.

Professional Detailing: A professional detailer can also restore the headlight lenses.

Replacement: If the lenses are severely damaged, consider replacing the entire headlight assembly.

Broken Headlight Assembly

Possible Causes:

- Accidents: Collisions or impacts can damage the headlight assembly.

- Vandalism: Intentional damage to the headlight assembly.

- Age and Wear: Over time, the headlight assembly can become brittle and crack or break.

Solution: Replace the damaged headlight assembly with a new or used one. Ensure the replacement assembly is compatible with your 1995 Nissan 240SX.

Estimated Repair Costs

Here's a rough estimate of repair costs. Keep in mind that these are just estimates, and the actual cost may vary depending on your location, the specific parts needed, and whether you do the work yourself or hire a mechanic.

- Headlight Bulb Replacement: $10 - $30 per bulb (DIY) / $30 - $60 per bulb (professional installation)

- Headlight Restoration Kit: $20 - $40 (DIY) / $80 - $150 (professional detailing)

- Headlight Assembly Replacement: $50 - $200 per assembly (used) / $100 - $400 per assembly (new) + labor costs if not DIY. Labor costs can range from $50 to $150 per headlight depending on the shop.

- Wiring Repair: $50 - $200, depending on the extent of the damage and labor costs.

- Headlight Switch Replacement: $30 - $100 for the switch + labor costs if not DIY.

Important Note: When purchasing replacement parts, especially electrical components, always buy from a reputable source to ensure quality and compatibility.

Final Thoughts

Dealing with headlight issues on your 240SX can be frustrating, but hopefully, this guide has provided you with some useful information and practical solutions. Remember to always prioritize safety and ensure your headlights are properly aligned and functioning correctly. If you're uncomfortable working on your car's electrical system, don't hesitate to consult a qualified mechanic. Good luck, and happy driving!