1995 Nissan 240sx Power Window Switch

Alright, let's dive into the power window switch on your 1995 Nissan 240sx (S14). This is a component that's often overlooked until it fails, leaving you stuck with a window that won't budge. We'll break down its operation, common failure points, troubleshooting, and even some potential modifications.

Understanding the 240sx Power Window Circuit

Before we dissect the switch itself, it’s essential to grasp the basic principles of the power window circuit in your S14. Think of it as a closed loop. The main components are:

- Battery: The power source, providing 12V DC electricity.

- Fuse: A safety device designed to blow if excessive current flows, protecting the wiring and components. Usually located in the fuse box, check your owner's manual for the specific power window fuse location and amperage rating.

- Power Window Switch: This is our main focus. It acts as a control hub, directing power flow to the window motor.

- Window Motor: A small electric motor that drives the window regulator, raising and lowering the glass.

- Wiring: Connects all the components, carrying the electrical current.

- Ground: Provides a return path for the current to the battery, completing the circuit. A good ground is absolutely crucial for proper operation.

The power window switch controls the polarity of the voltage supplied to the window motor. This polarity reversal dictates whether the motor rotates clockwise (raising the window) or counter-clockwise (lowering the window).

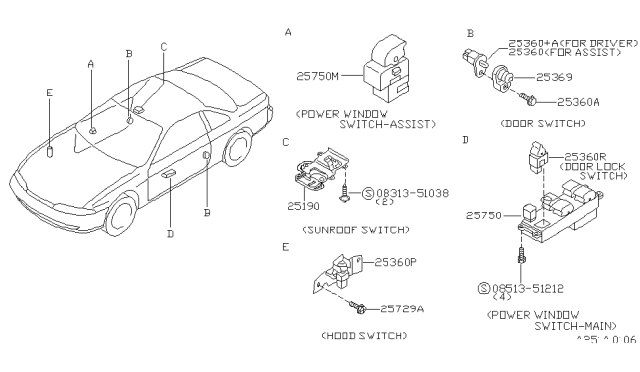

The Anatomy of the Power Window Switch

The stock 240sx power window switch isn't particularly complex, but understanding its internal workings will aid in troubleshooting. The switch typically comprises a few key elements:

- Housing: The physical casing that holds all the internal components together.

- Contacts: These are metallic points that make or break electrical connections. They are typically made of copper or brass. Over time, these contacts can corrode or become dirty, leading to intermittent operation or complete failure.

- Rocker/Lever: The part you physically manipulate to raise or lower the window. It mechanically moves the internal contacts.

- Springs: Provides resistance and helps return the rocker/lever to its neutral position.

- Wiring Harness Connector: Where the switch connects to the vehicle's wiring harness.

Inside the switch, when you press the rocker upwards, it pushes certain contacts together, creating a circuit that sends positive voltage to one terminal of the window motor and negative (ground) to the other, causing the motor to raise the window. Pressing the rocker downwards reverses this polarity, lowering the window.

Common Failure Points

Several factors can contribute to a faulty power window switch:

- Corrosion and Dirt: This is the most common culprit. Over time, dust, dirt, and moisture can infiltrate the switch, corroding the contacts and hindering their ability to make a good connection. This is especially prevalent in older vehicles.

- Wear and Tear: Constant use can wear down the contacts and internal mechanisms, leading to failure. Think of it like wearing down the brake pads on your car.

- Electrical Overload: A short circuit or excessive current draw in the window motor can damage the switch's internal components. While the fuse *should* protect it, repeated overloads can weaken the switch.

- Physical Damage: Dropping the switch or subjecting it to excessive force can break internal components.

- Wiring Issues: Problems within the wiring harness *connected* to the switch can *mimic* switch failure. This is why proper diagnosis is crucial.

Troubleshooting a Faulty Power Window Switch

Before replacing the switch, follow these steps to properly diagnose the problem. Remember to disconnect the battery's negative terminal before working on any electrical components.

- Visual Inspection: Check the switch for any visible signs of damage, such as cracks, broken levers, or corrosion.

- Fuse Check: Use a multimeter to verify that the power window fuse is intact. A blown fuse indicates a problem elsewhere in the circuit, such as a short circuit in the window motor or wiring.

- Test the Window Motor Directly: Disconnect the wiring harness from the window motor. Using jumper wires connected directly to the battery, carefully apply 12V to the motor terminals. Reverse the polarity to test both directions. If the motor works when powered directly, the problem lies *upstream*, likely in the switch or wiring. Warning: Be extremely careful when working with direct battery power. Avoid shorts.

- Continuity Test (Multimeter Required): Disconnect the switch from the wiring harness. Using a multimeter set to continuity mode (the "beep" setting), test the continuity between the various terminals of the switch while manipulating the rocker/lever. Consult the 240sx wiring diagram for the specific terminals to test. You should see continuity between the appropriate terminals when the switch is in the "up" or "down" position, and no continuity when in the neutral position. If you don't get the expected results, the switch is likely faulty.

- Voltage Test (Multimeter Required): With the ignition key in the "ON" position (but engine off), use a multimeter to check for voltage at the wiring harness connector that plugs into the power window switch. You should see 12V at the appropriate terminal. If you don't, there's a problem with the wiring leading to the switch, such as a broken wire or a bad connection.

- Ground Check (Multimeter Required): Using a multimeter set to continuity mode, check the ground connection at the switch's wiring harness. There should be near-zero resistance between the ground terminal and a known good ground point on the vehicle's chassis. A poor ground can cause all sorts of electrical problems.

- Check the Master Switch: If only one window isn't working, and the master switch on the driver's door controls all windows, test the master switch first. It's a common point of failure.

Repairing or Replacing the Switch

If the switch is determined to be the culprit, you have two main options:

- Repair: If the issue is simply dirty or corroded contacts, you can attempt to clean the switch. Disassemble the switch carefully (take pictures as you go!), clean the contacts with electrical contact cleaner and a small brush, and reassemble. This is a cost-effective solution if the damage isn't too severe. Be extremely careful with the small springs and components inside.

- Replace: If the switch is severely damaged or cleaning doesn't solve the problem, replacement is the best option. You can purchase a new OEM (Original Equipment Manufacturer) switch or an aftermarket replacement. Aftermarket switches can sometimes be cheaper, but quality can vary.

Installation is generally straightforward:

- Disconnect the battery negative terminal.

- Remove the old switch from the door panel (usually held in place by clips or screws).

- Disconnect the wiring harness from the old switch.

- Connect the wiring harness to the new switch.

- Install the new switch in the door panel.

- Reconnect the battery negative terminal.

- Test the window operation.

Potential Modifications and Upgrades

While the stock power window switch is functional, some owners choose to upgrade or modify it. Here are a few ideas:

- Aftermarket Switches: Explore different aftermarket switch designs and aesthetics. Some prefer a sleeker, more modern look.

- Relay Upgrade: Adding relays to the power window circuit can reduce the load on the switch and improve window motor performance. Relays act as remote switches, using a small current from the switch to control a larger current to the motor. This can help prevent switch burnout and improve window speed.

- One-Touch Auto-Up/Down: Integrate a module that provides one-touch auto-up and auto-down functionality for the windows. This requires additional wiring and a compatible module.

Important Note: When modifying the power window circuit, always use appropriately sized wiring and fuses to prevent electrical fires. Consult a qualified electrician if you're unsure about any aspect of the modification.

Final Thoughts

The 1995 Nissan 240sx power window switch is a relatively simple component, but its proper function is essential for comfortable driving. By understanding its operation, common failure points, and troubleshooting techniques, you can effectively diagnose and repair any problems that may arise. Remember to always prioritize safety when working with electrical systems, and don't hesitate to seek professional help if you're unsure about any aspect of the repair.