1995 Rack And Pinion Steering System Specifications

Let's dive deep into the intricacies of a 1995 rack and pinion steering system. This type of steering system, common in many vehicles of that era, offers a direct and responsive feel. While modern systems often incorporate electronic assistance and variable ratios, understanding the mechanics of a '95 system provides a solid foundation for appreciating the evolution of steering technology.

Components and Operation

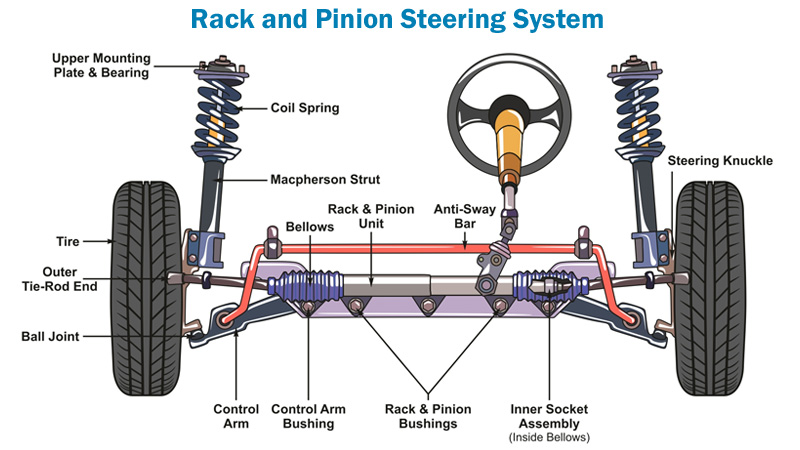

The rack and pinion system's primary goal is simple: translate the rotational motion of the steering wheel into the linear motion required to turn the wheels. It achieves this with a relatively small number of key components:

- Steering Wheel and Column: The driver's input point. The steering wheel is connected to the steering column, which transmits the rotational force downwards.

- Steering Shaft: Typically consists of one or more shafts connected by U-joints (universal joints). These U-joints allow for changes in angle between the steering wheel and the rack and pinion unit, accommodating the vehicle's chassis layout.

- Pinion Gear: A small, cylindrical gear located at the end of the steering shaft. This gear is the heart of the system, directly engaging with the rack.

- Rack: A linear toothed bar. As the pinion gear rotates, it meshes with the teeth on the rack, causing the rack to move either left or right, depending on the direction of rotation.

- Tie Rods: Connect the ends of the rack to the steering knuckles (also known as spindle carriers) on each front wheel. These rods transmit the linear motion of the rack to the wheels, causing them to turn.

- Steering Knuckles: The pivoting components to which the wheel hubs are mounted. The tie rods connect to the steering knuckles via ball joints, allowing for articulation and suspension movement.

- Ball Joints: Spherical bearings that allow the tie rods to move freely in multiple directions, accommodating the suspension's vertical travel and steering input.

- Power Steering Pump (if equipped): Provides hydraulic pressure to assist the driver in turning the steering wheel. A belt driven by the engine powers the pump.

- Power Steering Hoses (if equipped): High-pressure hoses that carry hydraulic fluid from the pump to the steering gear and back.

- Power Steering Gear Housing (if equipped): Contains the rack and pinion mechanism and incorporates hydraulic passages to provide power assist.

- Fluid Reservoir (if equipped): Stores power steering fluid.

The operation is straightforward. Turning the steering wheel rotates the steering shaft, which in turn rotates the pinion gear. The pinion gear’s rotation forces the rack to move linearly. This linear motion is then transferred through the tie rods to the steering knuckles, causing the wheels to pivot and the vehicle to turn. The gear ratio, the ratio between the rotation of the steering wheel and the movement of the wheels, determines the steering sensitivity. A lower ratio means less steering wheel rotation is needed for a given wheel angle, resulting in quicker, more responsive steering.

Power Steering Specifics (If Equipped)

In 1995, many vehicles offered power steering, which dramatically reduces the effort required to turn the steering wheel, especially at low speeds. This is achieved using hydraulic assistance.

The power steering pump generates hydraulic pressure, which is then directed to the steering gear. Inside the gear housing, a rotary valve controls the flow of hydraulic fluid to either side of a piston that is integrated with the rack. When the steering wheel is turned, the rotary valve opens, directing pressurized fluid to the appropriate side of the piston, assisting the rack's movement. The amount of assistance is proportional to the effort applied to the steering wheel. This hydraulic assist supplements the driver’s input, making steering easier.

A critical element is the pressure relief valve in the power steering pump. This valve prevents excessive pressure buildup in the system, protecting the pump and hoses from damage. It's also important to note that the power steering system requires regular maintenance, including fluid level checks and periodic fluid replacement, to ensure optimal performance and longevity.

Common Failure Points and Diagnostics

Rack and pinion steering systems, while generally reliable, can experience various problems over time. Understanding these issues and their symptoms is crucial for proper diagnosis and repair.

Common Problems:

- Loose Steering: Excessive play in the steering wheel before the wheels begin to turn. This can be caused by worn tie rod ends, ball joints, or internal wear within the rack and pinion unit itself.

- Hard Steering: Requires excessive effort to turn the steering wheel. This could be due to a failing power steering pump, low power steering fluid, a clogged power steering hose, or internal damage to the rack and pinion unit. If power steering is not equipped, hard steering may be caused by lack of lubrication or damage to the steering gear.

- Steering Wheel Vibration or Shimmy: Vibration felt through the steering wheel, especially at certain speeds. This can be caused by unbalanced tires, bent wheels, worn suspension components, or a failing rack and pinion unit.

- Noises (Groaning, Whining, Clicking): Unusual noises emanating from the steering system. Groaning or whining noises are often associated with a failing power steering pump. Clicking noises can indicate worn tie rod ends or ball joints.

- Fluid Leaks: Leaks from the power steering pump, hoses, or rack and pinion unit. Leaks can lead to low fluid levels, which can damage the pump and affect steering performance.

- Uneven Tire Wear: Can be caused by misaligned front wheels due to worn or damaged steering components.

Diagnostic Procedures:

Diagnosing steering system problems often involves a combination of visual inspection, physical examination, and, in some cases, specialized tools.

- Visual Inspection: Carefully inspect all steering components for signs of wear, damage, or leaks. Check tie rod ends and ball joints for looseness. Examine the rack and pinion unit for signs of leakage or damage to the boots.

- Physical Examination: With the vehicle safely supported, manually check for play in the tie rod ends and ball joints. Move the steering wheel back and forth slightly to check for excessive play in the steering system.

- Power Steering Fluid Check: Check the power steering fluid level and condition. Low fluid levels indicate a leak. Dark or contaminated fluid can indicate a failing pump.

- Pressure Testing (Power Steering): A pressure gauge can be used to measure the output pressure of the power steering pump. Low pressure indicates a failing pump.

- Alignment Check: A wheel alignment machine can be used to measure the alignment angles of the front wheels. Misalignment can indicate worn or damaged steering components.

Maintenance and Care

Proper maintenance is crucial for extending the life of a 1995 rack and pinion steering system.

- Regular Lubrication: Ensure that all grease fittings (if equipped) are lubricated regularly with a high-quality grease.

- Power Steering Fluid Maintenance: Check the power steering fluid level regularly and top off as needed. Replace the fluid according to the manufacturer's recommendations.

- Alignment Checks: Have the front wheel alignment checked periodically, especially after hitting a curb or pothole.

- Boot Inspection: Regularly inspect the rack and pinion boots for tears or damage. Replace damaged boots promptly to prevent dirt and debris from entering the steering gear.

- Prompt Repairs: Address any steering system problems promptly. Ignoring minor issues can lead to more serious and costly repairs down the road.

Evolution Beyond 1995

The 1995 rack and pinion system, while effective, has been further refined in modern vehicles. Electronic power steering (EPS) systems have largely replaced hydraulic power steering, offering improved fuel efficiency and greater control over steering assist. Variable steering ratios are also common, allowing for quicker steering at low speeds and greater stability at high speeds. However, understanding the foundational principles of the 1995 system provides a strong base for appreciating the advancements in steering technology.

Ultimately, the 1995 rack and pinion steering system represents a crucial stage in automotive engineering. Its simple yet effective design provided drivers with a responsive and reliable steering experience, paving the way for the more sophisticated systems we see today. A thorough understanding of its components, operation, and maintenance allows enthusiasts and aspiring engineers to appreciate the ingenuity behind this essential automotive technology.