2000 Nissan Frontier Exhaust Manifold

The 2000 Nissan Frontier, a popular compact pickup truck, relies on a robust and well-engineered exhaust system to manage the byproducts of combustion. A key component of this system is the exhaust manifold, a seemingly simple part with a crucial function. This guide provides an in-depth look at the exhaust manifold of a 2000 Nissan Frontier, exploring its design, function, materials, common issues, and potential upgrades.

Function and Purpose

The exhaust manifold's primary job is to collect exhaust gases from the engine's cylinders after the combustion process. Each cylinder expels hot, high-pressure gases through exhaust ports in the cylinder head. The manifold, bolted directly to the cylinder head, provides a passageway for these gases to converge. Think of it as a funnel, directing the exhaust flow into a single (or sometimes two, in the case of a V-engine) larger pipe, ultimately leading to the catalytic converter and the rest of the exhaust system.

Efficiently managing these exhaust gases is critical for several reasons:

- Reducing Backpressure: The smoother the flow of exhaust gases, the less backpressure the engine experiences. Excessive backpressure hinders the engine's ability to expel exhaust cleanly, reducing power output and fuel efficiency. A well-designed exhaust manifold minimizes restrictions and promotes a smoother flow.

- Emissions Control: While the catalytic converter bears the brunt of emissions reduction, the exhaust manifold plays a role in delivering exhaust gases to the converter at an appropriate temperature for optimal catalytic conversion. Some manifolds also incorporate provisions for air injection, which helps to burn off unburned hydrocarbons.

- Noise Reduction: While the muffler is primarily responsible for silencing the exhaust, the manifold contributes to overall noise reduction by initially containing and channeling the pulsating exhaust gases.

Design and Construction

The exhaust manifold on a 2000 Nissan Frontier is typically made of cast iron or, in some higher-performance or aftermarket applications, stainless steel. Cast iron manifolds are common due to their durability, heat resistance, and relatively low manufacturing cost. The design is generally a log-style manifold, which is a simpler design compared to tubular headers.

Material Considerations

- Cast Iron: The most common material, cast iron is chosen for its:

- High heat resistance: Withstanding the extreme temperatures of exhaust gases.

- Durability: Resisting cracking and warping over extended use.

- Cost-effectiveness: Being relatively inexpensive to manufacture.

- Stainless Steel: Aftermarket headers are often made from stainless steel. Stainless steel offers:

- Improved Flow: Tubular designs allow for smoother, less restrictive exhaust flow.

- Lighter Weight: Reducing overall vehicle weight.

- Corrosion Resistance: Providing longer life, especially in harsh environments.

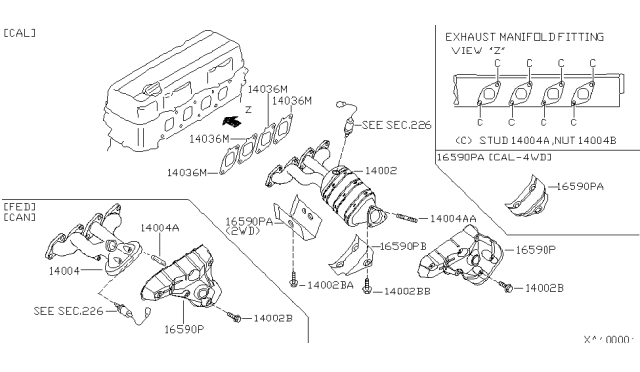

Layout and Configuration

The specific layout of the exhaust manifold depends on the engine configuration. The 2000 Frontier typically features either a 2.4L inline-four (KA24DE) or a 3.3L V6 (VG33E) engine. The inline-four engine has a single exhaust manifold that collects exhaust from all four cylinders. The V6 engine, on the other hand, has two exhaust manifolds, one for each bank of three cylinders. The manifolds are bolted to the cylinder head using studs and nuts, with a gasket in between to create a seal and prevent exhaust leaks. Pay close attention to the torque specifications when reinstalling the manifold to avoid warping or damaging the gasket.

Common Problems and Issues

Exhaust manifolds are subjected to extreme temperatures and pressures, making them susceptible to several common problems:

- Cracking: Repeated heating and cooling cycles can cause thermal stress, leading to cracks in the manifold, especially in cast iron versions. Cracks usually manifest around welds or areas of high stress concentration.

- Warping: Uneven heating can cause the manifold to warp, leading to exhaust leaks. Warping is more common in manifolds that have been overheated or improperly torqued during installation.

- Gasket Failure: The exhaust manifold gasket, usually made of a composite material, can degrade over time due to heat and pressure, leading to exhaust leaks.

- Stud Breakage: The studs that hold the manifold to the cylinder head can corrode and break, making it difficult to remove the manifold.

- Catalytic Converter Clogging: Though not directly the manifold's fault, a failing or clogged catalytic converter can increase backpressure in the exhaust system, which can exacerbate existing problems with the manifold and contribute to its early failure.

Symptoms of Exhaust Manifold Problems

Recognizing the signs of a failing exhaust manifold is crucial for timely repairs:

- Loud Exhaust Noise: An exhaust leak, often caused by a crack in the manifold or a failed gasket, will produce a noticeable increase in exhaust noise, particularly during acceleration. This noise is often described as a hissing or ticking sound.

- Reduced Fuel Efficiency: An exhaust leak can disrupt the engine's air-fuel ratio, leading to decreased fuel economy.

- Loss of Power: Excessive backpressure due to a clogged or damaged manifold can restrict exhaust flow, reducing engine power, especially at higher RPMs.

- Check Engine Light: An exhaust leak can trigger the check engine light, with codes related to oxygen sensor readings or lean/rich conditions.

- Burning Smell: Exhaust gases leaking from the manifold can sometimes produce a burning smell, especially if the gases are contacting other engine components.

Diagnosis and Repair

Diagnosing an exhaust manifold problem typically involves a visual inspection of the manifold and gasket for cracks, leaks, or damage. A common method is to use a soapy water solution sprayed around the manifold while the engine is running. Bubbles forming indicate an exhaust leak. A mechanic's stethoscope can also be used to pinpoint the location of an exhaust leak. For cracked manifolds, welding may be a temporary solution, but replacement is often the most reliable long-term fix. Gasket replacement is usually straightforward, but broken studs can complicate the process.

Repair Considerations

- Safety First: Always allow the engine to cool completely before working on the exhaust system to avoid burns.

- Penetrating Oil: Use a penetrating oil on the exhaust manifold studs several hours before attempting to remove them, to help loosen them and prevent breakage.

- Gasket Selection: Choose a high-quality replacement gasket to ensure a proper seal.

- Torque Specifications: Always tighten the exhaust manifold bolts to the manufacturer's specified torque to prevent warping or leaks. Follow a proper tightening sequence.

- Stud Replacement: If any studs are broken or corroded, replace them with new, high-quality studs.

Performance Upgrades and Aftermarket Options

For those seeking to improve the performance of their 2000 Nissan Frontier, aftermarket exhaust headers offer a potential upgrade over the stock cast iron manifold. Headers are typically made from stainless steel and feature a tubular design that promotes smoother exhaust flow and reduces backpressure. Long tube headers are especially effective at improving power, but they may require modifications to the exhaust system and are often not emissions-legal in all areas.

Considerations for Upgrading

- Legality: Ensure that any aftermarket exhaust modifications comply with local emissions regulations. Some headers may not be CARB (California Air Resources Board) compliant.

- Fitment: Verify that the headers are designed to fit your specific engine and chassis configuration.

- Performance Gains: Consider the potential performance gains relative to the cost of the upgrade. Header upgrades are most effective when combined with other performance modifications, such as a cold air intake and a performance exhaust system.

- Installation: Header installation can be more complex than simply replacing the stock manifold, and may require specialized tools and expertise.

- Tuning: To fully realize the potential benefits of header upgrades, it is often necessary to have the engine's computer (ECU) re-tuned to optimize the air-fuel ratio and ignition timing.

In conclusion, the exhaust manifold is a vital component of the 2000 Nissan Frontier's engine. Understanding its function, design, and common problems can help owners maintain their vehicles and potentially improve performance. By carefully considering the options and following proper repair procedures, enthusiasts and everyday drivers alike can ensure that their Frontier continues to run smoothly for years to come. Always consult a qualified mechanic if you are unsure about any aspect of exhaust system repair or modification.