2001 Nissan Maxima Cadillac Converter

The 2001 Nissan Maxima, a popular choice for its blend of performance and practicality, relies on a catalytic converter as a crucial component of its emission control system. This article delves into the technical intricacies of the 2001 Maxima's catalytic converter, exploring its function, design, common issues, and potential solutions.

What is a Catalytic Converter and Why is it Important?

At its core, a catalytic converter is an emissions control device that reduces harmful pollutants in an engine's exhaust gas stream. These pollutants, primarily hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx), are byproducts of the combustion process. Regulations mandate the reduction of these emissions to protect air quality and public health.

The converter achieves this reduction through chemical reactions catalyzed by precious metals, typically platinum, palladium, and rhodium. These metals are coated onto a ceramic substrate within the converter housing. The exhaust gases pass over this substrate, and the metals facilitate reactions that convert the harmful pollutants into less harmful substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2).

The 2001 Maxima, like most modern vehicles, utilizes a three-way catalytic converter. This type of converter simultaneously addresses all three main pollutant categories: hydrocarbons, carbon monoxide, and nitrogen oxides.

The 2001 Maxima's Catalytic Converter: Specifics

The exact design and specifications of the 2001 Maxima's catalytic converter can vary depending on the specific engine (either the VQ30DE or VQ35DE) and the vehicle's trim level. However, the fundamental principles remain the same.

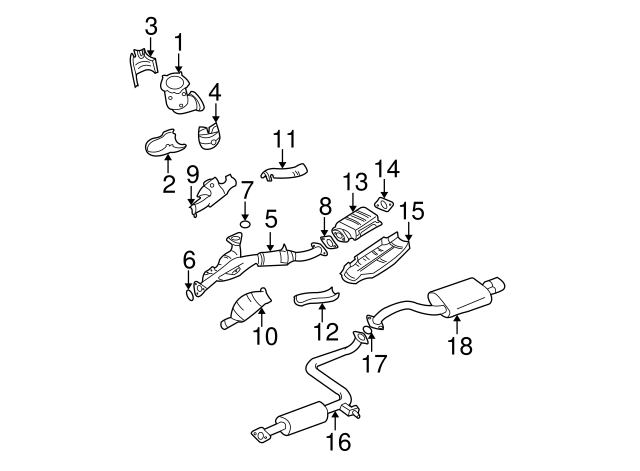

Typically, the 2001 Maxima will have at least one catalytic converter, and in some cases, two. The primary converter is usually located close to the exhaust manifold, maximizing its operating temperature. Higher temperatures improve catalytic efficiency. Some models may also have a secondary converter located further downstream in the exhaust system to further reduce emissions.

The substrate within the converter is usually a monolithic ceramic structure with a honeycomb-like design. This design provides a large surface area for the catalytic metals to react with the exhaust gases. The converter housing is constructed from stainless steel or aluminized steel to withstand the high temperatures and corrosive environment of the exhaust system.

Oxygen sensors play a critical role in the operation of the catalytic converter. One sensor is located upstream of the converter (before the exhaust gases enter the converter), and another is located downstream (after the exhaust gases exit the converter). The upstream sensor monitors the air-fuel ratio entering the engine and provides feedback to the engine control unit (ECU). The downstream sensor monitors the oxygen content of the exhaust gases exiting the converter and provides feedback on the converter's efficiency. This information allows the ECU to adjust the air-fuel ratio to optimize the converter's performance.

How the Three-Way Catalytic Converter Works

The "three-way" nature of the catalytic converter refers to its ability to address three different chemical reactions simultaneously:

1. Reduction of Nitrogen Oxides (NOx)

Nitrogen oxides are reduced to nitrogen and oxygen. Rhodium is the primary catalyst for this reaction:

2NOx → xO2 + N2

2. Oxidation of Carbon Monoxide (CO)

Carbon monoxide is oxidized to carbon dioxide. Platinum and palladium are the primary catalysts for this reaction:

2CO + O2 → 2CO2

3. Oxidation of Hydrocarbons (HC)

Hydrocarbons are oxidized to carbon dioxide and water. Platinum and palladium are the primary catalysts for this reaction:

4HC + 5O2 → 4CO2 + 2H2O

For these reactions to occur efficiently, the air-fuel ratio entering the converter must be tightly controlled. The ideal air-fuel ratio is approximately 14.7:1, which is known as the stoichiometric ratio. The ECU uses the oxygen sensor readings to maintain this ratio as closely as possible.

Common Problems and Symptoms

Catalytic converters can fail over time due to various factors. Some common issues include:

- Contamination: Leaded fuel, engine oil, or coolant entering the exhaust system can contaminate the catalytic converter and reduce its efficiency.

- Overheating: A rich-running engine can cause the converter to overheat, leading to damage and failure. This can happen if spark plugs are misfiring, causing unburnt fuel to enter the exhaust stream.

- Physical Damage: Impacts from road debris can damage the converter housing or the ceramic substrate.

- Age and Wear: Over time, the catalytic metals can become depleted, reducing the converter's efficiency.

Common symptoms of a failing catalytic converter include:

- Check Engine Light: The most common symptom is the illumination of the check engine light. Diagnostic trouble codes (DTCs) related to the catalytic converter, such as P0420 ("Catalyst System Efficiency Below Threshold"), will be stored in the ECU.

- Reduced Engine Performance: A clogged or inefficient converter can restrict exhaust flow, leading to reduced engine power, acceleration, and fuel economy.

- Rattling Noise: A damaged substrate can rattle inside the converter housing, creating a noticeable noise, especially during acceleration.

- Failed Emissions Test: A failing converter will likely cause the vehicle to fail an emissions test.

- Sulfur Smell: A rotten egg smell (sulfur) can indicate a problem with the catalytic converter. This is often caused by excessive sulfur in the fuel or a malfunctioning fuel system.

Diagnosis and Troubleshooting

Diagnosing a catalytic converter problem typically involves the following steps:

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve any stored DTCs. Codes related to the catalytic converter or oxygen sensors can provide clues to the problem.

- Inspect the Converter: Visually inspect the converter for any signs of physical damage, such as dents, cracks, or rust.

- Check Oxygen Sensor Readings: Use a scan tool to monitor the oxygen sensor readings upstream and downstream of the converter. The downstream sensor reading should be relatively stable compared to the upstream sensor reading if the converter is functioning properly. Large fluctuations in the downstream sensor reading can indicate a problem with the converter.

- Exhaust Backpressure Test: A backpressure test can be performed to check for restrictions in the exhaust system, including the catalytic converter. Excessive backpressure can indicate a clogged converter.

Replacement and Repair

If the catalytic converter is determined to be faulty, replacement is usually the best option. While some repairs, such as welding cracks in the housing, may be possible, they are often temporary fixes.

When replacing the catalytic converter, it's crucial to use a high-quality replacement that meets or exceeds the original equipment manufacturer (OEM) specifications. Aftermarket converters are available, but their quality can vary significantly. It's often worth investing in a reputable brand to ensure proper performance and longevity.

Before replacing the converter, it's essential to address the underlying cause of the failure. For example, if the converter failed due to a rich-running engine, the engine problem must be resolved to prevent the new converter from failing prematurely. Common causes include faulty oxygen sensors, fuel injectors, or spark plugs.

After replacing the catalytic converter, it's recommended to clear the DTCs from the ECU and perform a drive cycle to ensure that the system is functioning properly. The oxygen sensor readings should be monitored to verify that the new converter is operating efficiently.

Conclusion

The catalytic converter is an essential component of the 2001 Nissan Maxima's emission control system. Understanding its function, potential problems, and diagnostic procedures can help owners maintain their vehicle's performance and comply with emissions regulations. Regular maintenance and prompt attention to any warning signs can help extend the life of the catalytic converter and ensure optimal engine performance. By understanding the inner workings of this vital component, owners can make informed decisions regarding its care and maintenance, contributing to a cleaner and more efficient driving experience.