2004 Nissan Quest Catalytic Converter

The 2004 Nissan Quest, a minivan known for its practicality and family-friendly features, relies on a catalytic converter as a crucial component of its emissions control system. This seemingly simple device plays a complex and vital role in reducing harmful pollutants before they are released into the atmosphere. Understanding the 2004 Quest's catalytic converter requires delving into its design, function, common failure points, and replacement considerations. This guide provides an in-depth look at this often-overlooked, yet critically important, part of your vehicle.

Catalytic Converter Fundamentals

At its core, a catalytic converter is a reaction chamber designed to transform noxious exhaust gases produced during internal combustion into less harmful substances. These gases, primarily hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx), are products of incomplete combustion and contribute significantly to air pollution. The converter uses catalysis, a process where chemical reactions are accelerated by the presence of a catalyst, without the catalyst itself being consumed.

The typical catalytic converter consists of a ceramic or metallic substrate coated with a catalyst material. This substrate is usually shaped like a honeycomb or a collection of beads, maximizing the surface area available for the exhaust gases to interact with the catalyst. The catalyst itself typically comprises precious metals, most commonly platinum, palladium, and rhodium. Platinum and palladium promote the oxidation of HC and CO, while rhodium reduces NOx into nitrogen (N2) and oxygen (O2).

Two-Way vs. Three-Way Converters

Older catalytic converters were often two-way converters, designed to only oxidize HC and CO. However, modern vehicles like the 2004 Nissan Quest utilize three-way converters, which simultaneously reduce NOx in addition to oxidizing HC and CO. This necessitates a precise air-fuel ratio maintained by the engine's control system, as the NOx reduction process is most effective under slightly rich conditions (slightly more fuel than air), while the HC and CO oxidation is most effective under slightly lean conditions (slightly more air than fuel). The engine control unit (ECU) relies on oxygen sensors placed upstream and downstream of the catalytic converter to monitor the exhaust gas composition and adjust the air-fuel mixture accordingly, ensuring optimal converter performance.

The 2004 Nissan Quest's Catalytic Converter System

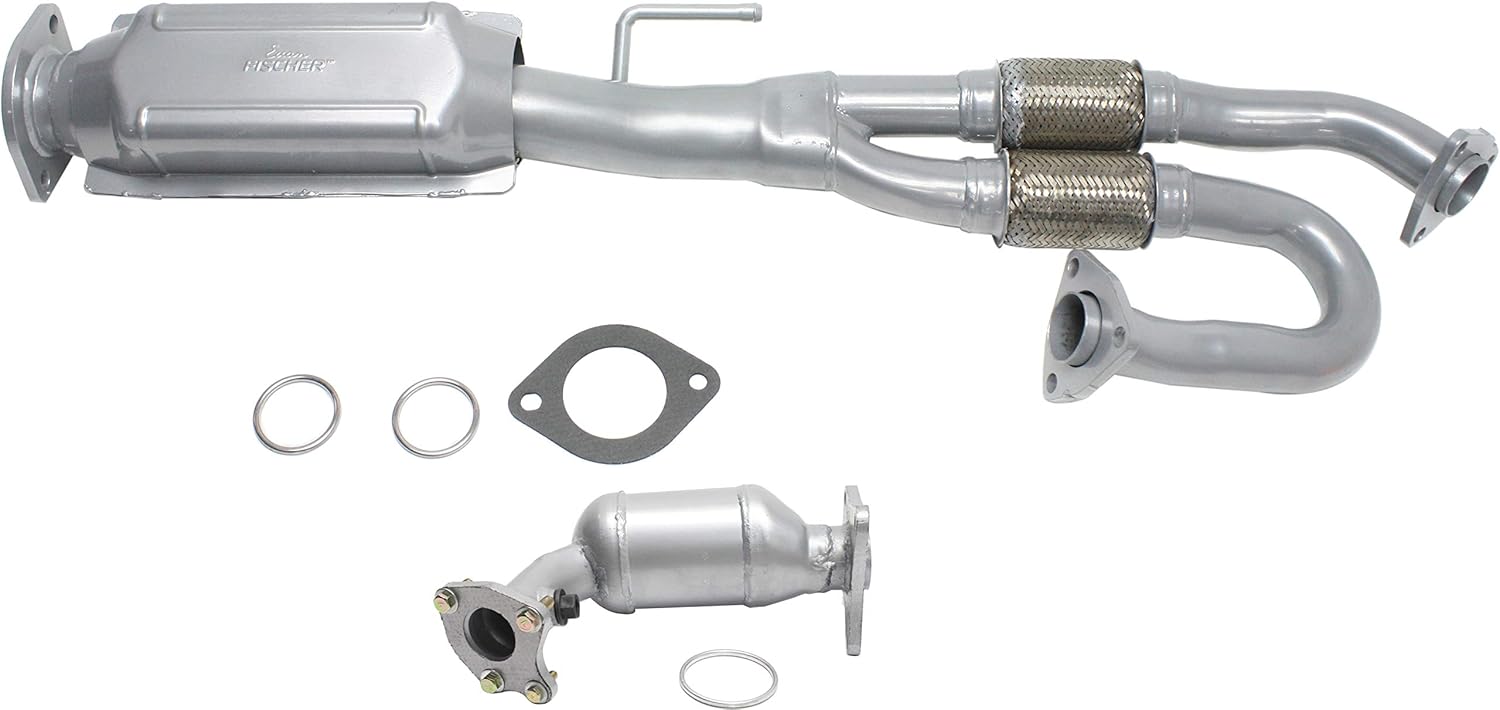

The 2004 Nissan Quest, powered by a 3.5-liter V6 engine, features a more complex catalytic converter arrangement than some older vehicles. It typically employs multiple catalytic converters – often a pre-converter located closer to the exhaust manifold and a main converter further downstream. This design aims to achieve quicker converter light-off (reaching operating temperature) and improved overall emissions reduction.

The pre-converter, positioned closer to the engine, heats up faster due to the higher exhaust gas temperatures. This allows it to begin catalyzing reactions sooner after engine start-up, which is a critical period for emissions control. The main converter then further reduces any remaining pollutants that passed through the pre-converter. The oxygen sensors play a crucial role in monitoring the efficiency of both converters. The upstream sensor provides feedback to the ECU to control the air-fuel ratio, while the downstream sensor monitors the converter's performance. If the downstream sensor detects an increase in HC, CO, or NOx levels, it indicates that the converter is not functioning properly and will typically trigger the "Check Engine" light.

Location and Construction

The precise location of the catalytic converters on the 2004 Quest can vary slightly depending on the specific model and trim level. However, they are generally situated within the exhaust system, downstream of the exhaust manifolds and upstream of the muffler. They are typically enclosed in a metal housing to protect the delicate internal components from damage and to maintain operating temperatures. The housing is designed to withstand the high temperatures and corrosive environment of the exhaust system.

Common Catalytic Converter Problems

Catalytic converters are robust components, but they are not immune to failure. Several factors can contribute to their malfunction, leading to reduced performance and potentially triggering the "Check Engine" light. Understanding these potential causes is essential for proper diagnosis and maintenance.

- Contamination: The most common cause of catalytic converter failure is contamination by substances that coat or poison the catalyst material. This can include oil, coolant, engine additives, or leaded fuel (although leaded fuel is highly uncommon in modern vehicles). These contaminants reduce the catalyst's ability to promote chemical reactions, decreasing its efficiency.

Oil leaks from worn valve stem seals or piston rings can introduce oil into the combustion chamber, eventually finding its way into the exhaust and poisoning the catalytic converter.

- Overheating: Excessive heat can also damage a catalytic converter. This can occur due to a misfiring engine, which dumps unburned fuel into the exhaust system. This unburned fuel ignites within the converter, causing a rapid and significant temperature increase that can melt or degrade the catalyst material.

- Physical Damage: Impact damage from road debris or accidents can physically damage the converter housing or the internal substrate. A cracked or damaged substrate reduces the surface area available for catalysis, decreasing its efficiency.

- Age and Wear: Over time, the catalyst material can degrade naturally due to repeated heating and cooling cycles and exposure to exhaust gases. This gradual degradation reduces the converter's ability to effectively reduce emissions.

- Faulty Oxygen Sensors: Malfunctioning oxygen sensors can provide incorrect feedback to the ECU, leading to an improper air-fuel ratio. This, in turn, can overload the catalytic converter and contribute to its failure.

Symptoms of a Failing Catalytic Converter

Recognizing the symptoms of a failing catalytic converter is crucial for timely diagnosis and repair, preventing further damage to the vehicle and minimizing emissions.

- Illuminated "Check Engine" Light: This is often the first and most obvious sign of a problem. Diagnostic trouble codes (DTCs) related to catalytic converter efficiency (e.g., P0420, P0430) will typically be stored in the ECU's memory.

- Reduced Engine Performance: A clogged or inefficient catalytic converter can restrict exhaust flow, leading to a noticeable reduction in engine power and acceleration.

- Poor Fuel Economy: The engine may have to work harder to overcome the exhaust restriction, resulting in decreased fuel efficiency.

- Rattling Noise: A damaged or broken internal substrate can create a rattling noise from within the converter housing, especially during acceleration or deceleration.

- Failed Emissions Test: If the catalytic converter is not functioning properly, the vehicle will likely fail an emissions test, preventing it from being legally operated on public roads.

- Sulfur Smell: In some cases, a failing catalytic converter can produce a sulfur-like smell (often described as rotten eggs), particularly during acceleration.

Diagnosis and Replacement

Diagnosing a catalytic converter problem typically involves a combination of visual inspection, diagnostic code reading, and potentially, exhaust gas analysis. A qualified technician can use a scan tool to retrieve any stored DTCs and to monitor the oxygen sensor readings. An exhaust gas analyzer can be used to measure the levels of HC, CO, and NOx in the exhaust stream, providing a more direct assessment of the converter's performance.

If the catalytic converter is determined to be faulty, replacement is often the only viable solution. There are several options available, ranging from aftermarket converters to OEM (Original Equipment Manufacturer) replacements. OEM converters are generally more expensive but are designed to meet the exact specifications of the original part. Aftermarket converters can be a more affordable alternative, but it's crucial to choose a reputable brand that meets applicable emissions standards. Ensure that the replacement converter is certified to meet EPA or CARB (California Air Resources Board) requirements, depending on your location.

Replacement involves removing the old converter and installing the new one. This typically requires disconnecting the exhaust system components, removing any associated oxygen sensors, and then bolting or welding the new converter into place. After installation, it's important to clear any stored DTCs from the ECU and to verify that the oxygen sensors are functioning correctly.

In conclusion, the catalytic converter on the 2004 Nissan Quest is a critical component of the vehicle's emissions control system. Understanding its function, potential failure modes, and symptoms of malfunction is essential for maintaining optimal engine performance and minimizing environmental impact. Regular maintenance, including addressing any engine issues that could contribute to converter failure, can help to extend the lifespan of this important component.