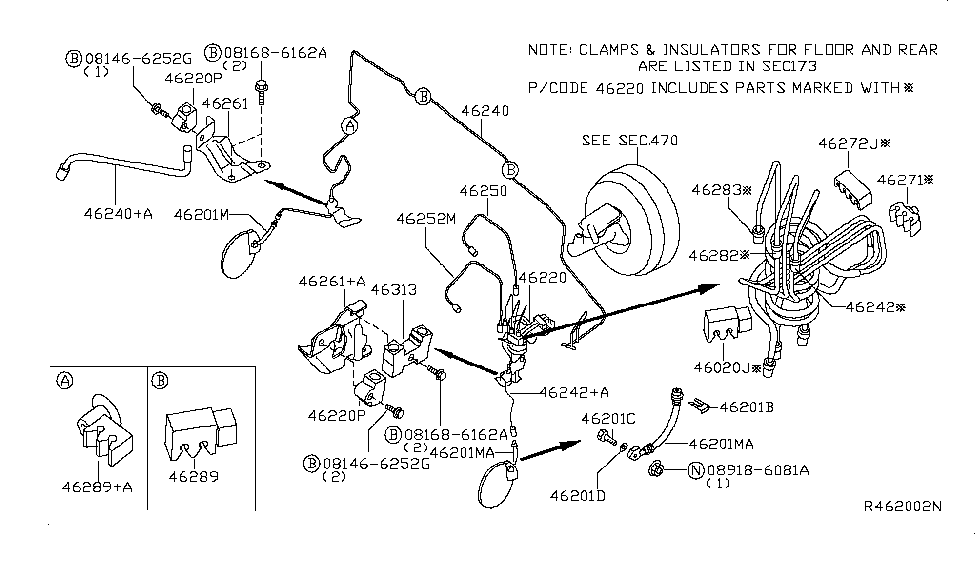

2004 Nissan Titan Brake Line Diagram

The 2004 Nissan Titan, a full-size pickup truck, relies on a hydraulic braking system to safely and effectively bring the vehicle to a halt. Understanding the brake line diagram is crucial for troubleshooting issues, performing maintenance, and ensuring the overall safety of the vehicle. This guide provides an in-depth look at the system, examining its components and layout, while aiming to provide an approachable introduction for anyone with a general curiosity or a drive to tinker.

Hydraulic Braking System Fundamentals

Before diving into the specific layout of the 2004 Titan's brake lines, it's important to understand the basic principles of a hydraulic braking system. This type of system uses a non-compressible fluid (brake fluid) to transmit force from the driver's foot on the brake pedal to the brake calipers and wheel cylinders at each wheel.

Here's a simplified overview of the process:

- When the driver presses the brake pedal, the master cylinder is activated.

- The master cylinder contains a piston that pressurizes the brake fluid within the brake lines.

- This pressurized fluid travels through the brake lines to the calipers (in disc brake systems) or wheel cylinders (in drum brake systems) at each wheel.

- The pressure forces the calipers to clamp the brake pads against the brake rotors, or the wheel cylinders to push the brake shoes against the brake drums.

- This friction slows down the wheels, bringing the vehicle to a stop.

The entire system must be free of leaks and air bubbles to function properly. Any compromise in the hydraulic integrity will result in reduced braking performance and a potentially dangerous situation.

2004 Nissan Titan Brake Line Diagram: A Detailed Look

The brake line system in the 2004 Nissan Titan can be broken down into several key sections:

1. Master Cylinder and Brake Booster

The master cylinder is the heart of the braking system. It's typically mounted on the firewall, directly in front of the driver's seat. The 2004 Titan uses a tandem master cylinder, meaning it has two separate hydraulic circuits. This provides a degree of redundancy – if one circuit fails, the other can still provide some braking power. The master cylinder is assisted by the brake booster, a vacuum-assisted or hydraulically-assisted device that amplifies the force applied by the driver's foot, making it easier to press the brake pedal.

From the master cylinder, two main brake lines emerge. These lines are often referred to as the primary and secondary circuits.

2. Primary and Secondary Brake Circuits

The 2004 Titan, like most modern vehicles, utilizes a split braking system for safety. The most common configuration is a diagonal split. Let’s say the primary circuit is dedicated to the front left wheel and the rear right wheel, while the secondary circuit goes to the front right and the rear left wheel. This design ensures that if one circuit fails, the driver will still have braking force on at least one front wheel, which is critical for maintaining steering control. This is important for safe stops under less-than-ideal conditions.

3. Proportioning Valve (or Combination Valve)

A proportioning valve, or often a combination valve (which integrates other functions), is typically located downstream from the master cylinder. Its primary function is to regulate the brake pressure applied to the rear wheels. Without a proportioning valve, the rear wheels could lock up before the front wheels during hard braking. This is because the weight distribution shifts forward under deceleration, reducing the load on the rear wheels and making them more susceptible to locking. The proportioning valve reduces the pressure to the rear brakes, preventing premature lockup and improving stability.

Modern vehicles may also use electronic brake-force distribution (EBD) as part of the Anti-lock Braking System (ABS), which dynamically adjusts the braking force at each wheel based on sensor data. The 2004 Titan offered ABS as an option, which would include EBD.

4. Brake Lines and Hoses

The brake lines themselves are typically made of steel tubing, which is rigid and durable. These lines run along the vehicle's frame, connecting the master cylinder, proportioning valve, and ABS modulator (if equipped) to the flexible brake hoses near each wheel.

Brake hoses are made of flexible rubber or reinforced materials. They are necessary because the wheels move independently of the vehicle's chassis. These hoses allow the brake fluid to flow to the calipers or wheel cylinders without being damaged by the movement of the suspension.

5. Front Brake Calipers and Rear Brakes (Disc or Drum)

The 2004 Nissan Titan typically features disc brakes on the front wheels. These consist of a caliper, brake pads, and a rotor. The brake lines connect directly to the calipers. When the brake pedal is pressed, the pressurized brake fluid forces the caliper's piston(s) to clamp the brake pads against the rotor, creating friction and slowing the wheel.

The rear brakes on the 2004 Titan could be either disc brakes or drum brakes depending on the specific trim level and options. If equipped with drum brakes, the brake lines connect to the wheel cylinders. When the brake pedal is pressed, the pressurized fluid forces the wheel cylinder pistons to push the brake shoes against the inside of the brake drum, creating friction and slowing the wheel.

6. Anti-lock Braking System (ABS)

If the 2004 Titan is equipped with ABS, the brake lines will run through an ABS modulator. The ABS modulator is a complex unit that monitors wheel speed sensors at each wheel. If the system detects that a wheel is about to lock up during braking, the ABS modulator rapidly modulates the brake pressure to that wheel, preventing the lockup and allowing the driver to maintain steering control. This modulation is accomplished through a series of valves and pumps within the modulator.

Troubleshooting Brake Line Issues

Several problems can arise within the brake line system, leading to reduced braking performance or even complete brake failure. Here are some common issues:

- Leaks: Brake fluid leaks are a common problem, usually occurring at fittings, hoses, or the master cylinder. Leaks reduce the amount of pressure that can be generated in the system, resulting in a soft or spongy brake pedal and reduced stopping power.

- Air in the Lines: Air can enter the brake lines if the system is opened (e.g., during brake repairs) or if there is a leak. Air is compressible, unlike brake fluid, and its presence will reduce the effectiveness of the braking system. Bleeding the brakes is necessary to remove air from the lines.

- Corroded or Damaged Brake Lines: Over time, steel brake lines can corrode, especially in areas where salt is used on the roads. Corroded brake lines can weaken and eventually rupture, leading to a loss of brake fluid and brake failure. Physical damage to brake lines can also occur, especially off-road.

- Collapsed Brake Hoses: Brake hoses can deteriorate internally over time, causing them to collapse. A collapsed brake hose can restrict the flow of brake fluid, leading to uneven braking or a stuck brake caliper.

Performing Maintenance and Repairs

Regular maintenance is essential to keep the brake line system in good working order. This includes:

- Checking Brake Fluid Level: Regularly check the brake fluid level in the master cylinder reservoir and top it off as needed. Use only the brake fluid type specified in the owner's manual (usually DOT 3 or DOT 4).

- Inspecting Brake Lines and Hoses: Visually inspect the brake lines and hoses for signs of corrosion, leaks, cracks, or damage. Replace any damaged components immediately.

- Bleeding the Brakes: Bleed the brakes periodically to remove air from the lines. This is especially important after performing brake repairs or if the brake pedal feels spongy.

- Replacing Brake Fluid: Brake fluid absorbs moisture over time, which can lead to corrosion and reduced braking performance. Replace the brake fluid every two to three years.

Warning: Working on brake systems can be dangerous. If you are not comfortable performing brake repairs, it is best to take your vehicle to a qualified mechanic. Improper brake repairs can lead to brake failure and serious accidents.

Conclusion

Understanding the 2004 Nissan Titan brake line diagram is crucial for both general knowledge and practical maintenance. By familiarizing yourself with the components and layout of the system, you can better diagnose problems, perform necessary repairs, and ensure the safe and reliable operation of your vehicle's brakes. Remember to always prioritize safety and consult a qualified mechanic if you are unsure about any aspect of brake system maintenance or repair. Remember: safety first! Keeping the hydraulic system sound will make sure the braking system of your vehicle works when it needs to.