2005 Nissan Altima 2.5 S Fuel Pump

The 2005 Nissan Altima 2.5 S, a popular mid-size sedan, relies on a robust fuel system to deliver gasoline to its engine. At the heart of this system lies the fuel pump, a critical component responsible for providing a consistent and reliable fuel supply. This guide delves into the intricacies of the 2005 Altima 2.5 S fuel pump, examining its function, construction, operation, potential issues, and troubleshooting methods.

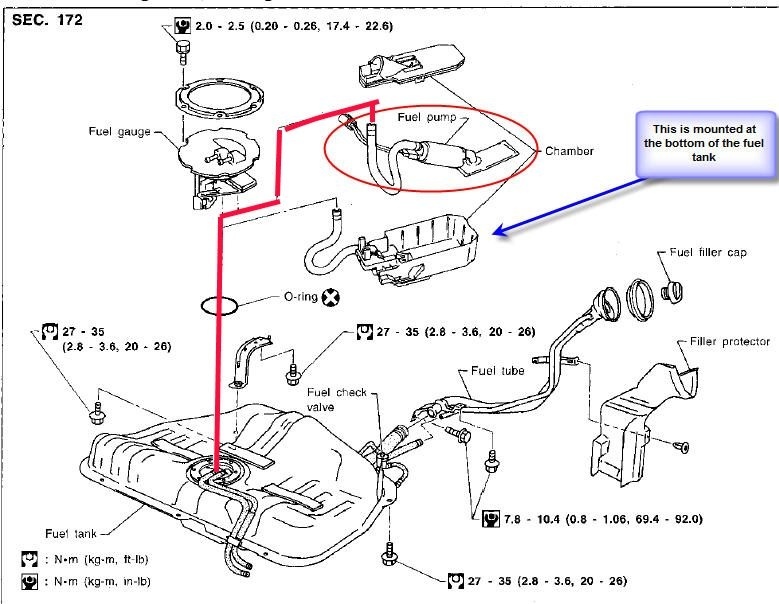

Fuel Pump Function and Location

The fuel pump's primary function is to transfer fuel from the fuel tank to the engine, maintaining adequate pressure within the fuel lines. This pressure is crucial for the proper operation of the fuel injectors, which meter the fuel delivered to the cylinders for combustion. In the 2005 Altima 2.5 S, the fuel pump is an in-tank electric fuel pump, meaning it's located inside the fuel tank. This submerged location offers several advantages:

- Cooling: The fuel itself acts as a coolant, helping to dissipate heat generated by the pump's electric motor, thereby extending its lifespan.

- Noise Reduction: Submerging the pump dampens the noise produced by its operation.

- Reduced Vapor Lock: Being submerged reduces the risk of vapor lock, a condition where fuel vaporizes in the fuel lines, hindering fuel delivery.

Accessing the fuel pump typically requires removing the rear seat cushion to expose the fuel pump access panel located underneath.

Fuel Pump Assembly and Components

The 2005 Altima 2.5 S fuel pump isn't just a simple pump; it's an assembly comprising several key components:

- Electric Fuel Pump: This is the core of the assembly, typically a gerotor or turbine-type pump driven by a small electric motor. The motor draws power from the vehicle's electrical system to create suction and pressure.

- Fuel Strainer (Sock): A filter, often referred to as a "sock," is attached to the pump's inlet. This strainer prevents large particles and debris from entering the pump, protecting it from damage and ensuring a clean fuel supply.

- Fuel Pressure Regulator: While not always integrated directly *on* the pump itself on all vehicles, the fuel pressure regulator plays a critical role in maintaining a constant fuel pressure at the fuel rail. Excess fuel is routed back to the fuel tank via a return line. On some later models, the regulator is integrated into the fuel pump assembly. The 2005 Altima 2.5 S utilizes a return style fuel system, meaning a mechanical fuel pressure regulator controls pressure at the fuel rail and returns excess fuel to the tank.

- Fuel Level Sending Unit: This component measures the fuel level in the tank and transmits the information to the fuel gauge on the instrument panel. It's often a float connected to a variable resistor.

- Fuel Reservoir/Sump: A small reservoir surrounding the pump ensures that the pump remains submerged in fuel, even when the fuel level is low or during cornering, preventing fuel starvation.

- Check Valve: Located within the pump assembly, the check valve maintains fuel pressure in the fuel lines when the engine is off, aiding in easier starting.

Fuel Pump Operation

When the ignition key is turned to the "ON" position (but before starting), the Engine Control Module (ECM) activates the fuel pump relay. This relay supplies power to the fuel pump's electric motor. The motor then spins, drawing fuel through the strainer and pumping it through the fuel lines to the fuel rail.

The fuel pressure regulator maintains a constant fuel pressure. Any fuel not used by the injectors is returned to the fuel tank via the return line. Once the engine starts, the ECM continuously monitors engine parameters and adjusts fuel delivery accordingly. The fuel pump operates continuously while the engine is running.

The system relies on a closed loop. The ECM monitors the oxygen sensor(s) in the exhaust. These sensors feedback information about the air-fuel mixture. If the mixture is too lean (too much air, not enough fuel), the ECM commands the injectors to open for a longer duration, injecting more fuel. If the mixture is too rich (too much fuel, not enough air), the ECM reduces the injector pulse width.

Common Fuel Pump Problems

Like any mechanical device, the fuel pump is susceptible to wear and tear and can eventually fail. Several factors can contribute to fuel pump problems in the 2005 Altima 2.5 S:

- Contaminated Fuel: Debris and contaminants in the fuel can clog the fuel strainer and damage the pump's internal components, reducing its efficiency and lifespan. Regularly changing the fuel filter (an inline filter, typically located under the vehicle) helps mitigate this.

- Running on Low Fuel: Consistently operating the vehicle with a low fuel level can cause the fuel pump to overheat. When the fuel level is low, the pump is less effectively cooled by the surrounding fuel. Overheating can damage the motor windings and shorten the pump's lifespan.

- Electrical Issues: Problems with the fuel pump relay, wiring harness, or ground connections can prevent the pump from receiving adequate power, leading to intermittent operation or complete failure. Corrosion and loose connections are common culprits.

- Age and Wear: Over time, the fuel pump's internal components can simply wear out due to normal use. The motor's brushes can wear down, the pump's internal seals can deteriorate, and the pump's efficiency can decrease.

- Ethanol Content: While the 2005 Altima 2.5 S is designed to handle fuels with some ethanol, excessive ethanol content (above the specified limit) can corrode fuel system components over time.

Symptoms of a Failing Fuel Pump

Several symptoms can indicate a failing fuel pump:

- Difficulty Starting: A failing fuel pump may not be able to provide sufficient fuel pressure to start the engine, resulting in prolonged cranking or failure to start.

- Stalling: The engine may stall, especially under load or when accelerating. This occurs when the fuel pump cannot maintain adequate fuel pressure to meet the engine's demands.

- Hesitation or Loss of Power: The engine may hesitate or experience a loss of power, particularly during acceleration. This is often a sign of reduced fuel pump output.

- Rough Idle: An inconsistent fuel supply can cause the engine to idle roughly.

- Poor Fuel Economy: A failing fuel pump may deliver fuel inefficiently, resulting in decreased fuel economy.

- Whining Noise from Fuel Tank: A failing fuel pump may emit a noticeable whining noise from the fuel tank. This noise is often caused by the pump struggling to draw fuel or by worn internal components.

- Check Engine Light: A failing fuel pump can trigger the check engine light, and diagnostic trouble codes (DTCs) related to fuel delivery (e.g., P0087, P0088, P0191) may be stored in the ECM.

Troubleshooting the Fuel Pump

Diagnosing fuel pump problems requires a systematic approach:

- Check the Fuel Pump Relay and Fuse: Use a multimeter or test light to verify that the fuel pump relay is receiving power and that the fuse is intact. Replace any blown fuses or faulty relays. Refer to the vehicle's wiring diagram for the location of these components.

- Check Fuel Pressure: Use a fuel pressure gauge connected to the fuel rail test port to measure fuel pressure. Compare the reading to the manufacturer's specifications. Low fuel pressure can indicate a failing fuel pump, a clogged fuel filter, or a faulty fuel pressure regulator.

- Listen for Fuel Pump Operation: With the ignition key in the "ON" position (but before starting), listen for the fuel pump to prime. A healthy fuel pump should emit a brief buzzing sound. If you don't hear anything, the pump may not be receiving power or may be completely dead.

- Check for Voltage at the Fuel Pump: Use a multimeter to check for voltage at the fuel pump connector. If voltage is present, the pump is receiving power, but may still be faulty. If no voltage is present, there is an electrical problem in the wiring harness, relay, or ECM.

- Inspect the Fuel Strainer: If possible, remove the fuel pump assembly and inspect the fuel strainer for clogs or debris. Clean or replace the strainer as needed.

- Check the Ground Connection: Ensure the fuel pump's ground connection is clean and secure. A poor ground connection can cause intermittent fuel pump operation.

- Consider a Fuel Pump Test: Some auto parts stores offer fuel pump testing services. This involves removing the fuel pump and testing its output and pressure on a specialized bench tester.

Important Note: Working on the fuel system can be dangerous due to the flammability of gasoline. Always disconnect the negative battery cable before working on the fuel system, and work in a well-ventilated area. Have a fire extinguisher readily available.

Replacement Considerations

If the fuel pump is determined to be faulty, replacement is usually the most reliable solution. When replacing the fuel pump, consider the following:

- Quality: Opt for a reputable brand and a fuel pump that meets or exceeds the original equipment (OE) specifications.

- Complete Assembly: Consider replacing the entire fuel pump assembly, including the fuel strainer, fuel pressure regulator (if applicable), and fuel level sending unit. This can help prevent future problems and ensure proper operation.

- Installation: Follow the manufacturer's instructions carefully when installing the new fuel pump. Ensure all connections are secure and that the fuel lines are properly connected. Replace any worn or damaged fuel lines or connectors.

- Fuel Filter: Replace the fuel filter at the same time as the fuel pump. This ensures a clean fuel supply and protects the new pump from contamination.

By understanding the function, components, operation, and potential issues of the 2005 Nissan Altima 2.5 S fuel pump, owners and enthusiasts can better diagnose and address fuel system problems, ensuring optimal engine performance and reliability. Remember to always prioritize safety when working with fuel systems.